Test-tube taking and placing device

A pick-and-place device and test tube technology, applied in the direction of test tube brackets/clamps, etc., can solve the problems of high risk, high equipment cost, waste of resources, etc., and achieve the effect of solving disinfection and sterilization resources, reducing experimental risks, and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

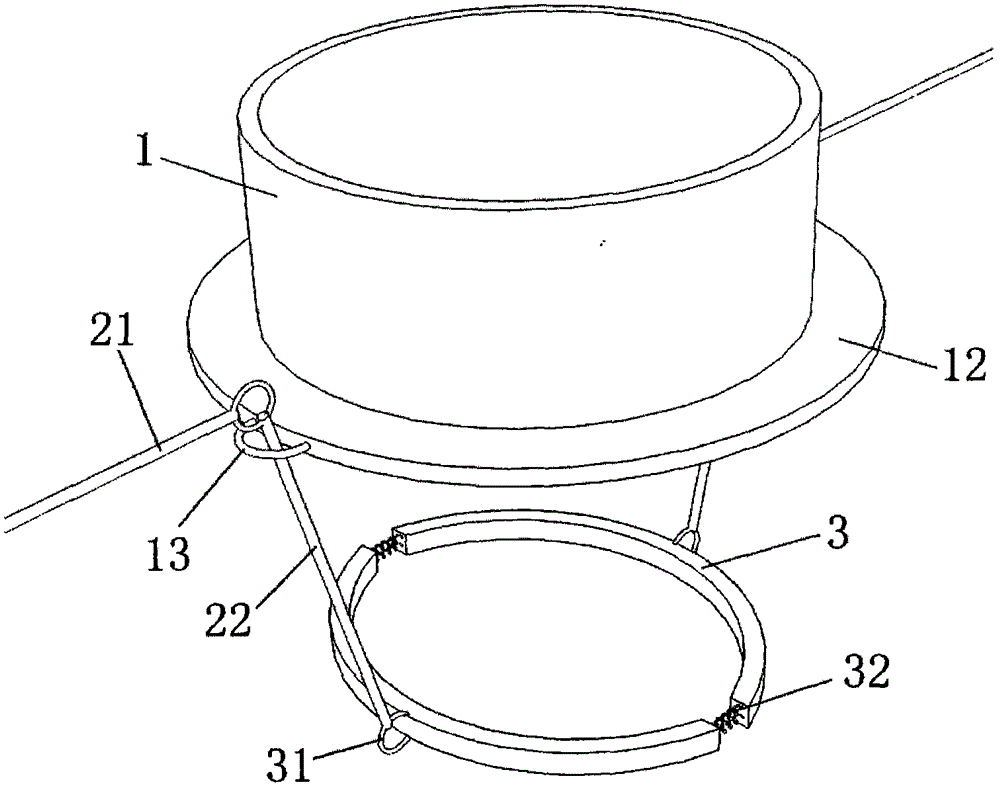

[0013] Such as figure 1 A test tube pick-and-place device shown includes an operating ring 1, a transverse rod 21, a moving rod 22, and a clamping ring 3; the operating ring 1 is a vertically arranged cylindrical ring, and its bottom edge is opposite to a fixed ring 13 ; The horizontal rod 21 is horizontally arranged above the fixed ring 13; the moving rod 22 passes through the fixed ring 13 from the vertical direction; 3 are arranged horizontally opposite to each other and connected by the ends of the elastic structure; the clamping ring 3 is provided with a pull ring 31 at the top of the arc; Pull ring 31 in.

[0014] Thus, the transverse rod 21 is arranged in the sterile room, and the position of the operating ring 1 is adjusted through the transverse rod 21 during use, and a single test tube can be taken and placed by looseni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com