Butterfly-shaped garbage sieve

A kind of garbage butterfly and butterfly technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of poor actual effect, jamming, large influence of screening rate, etc. The effect of screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

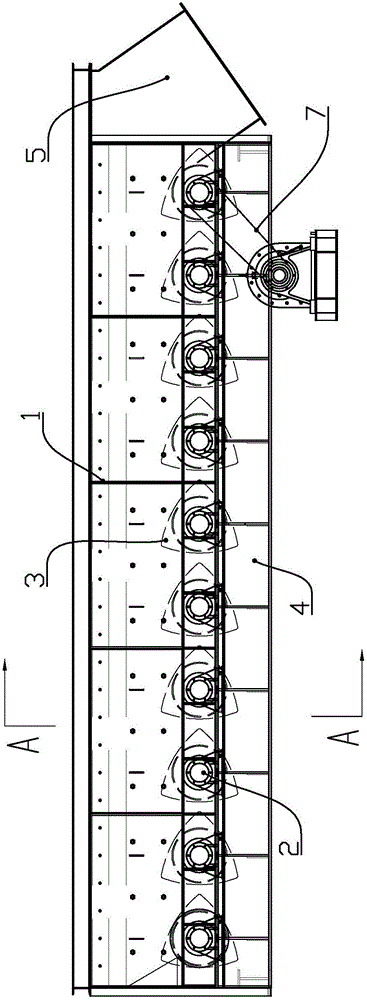

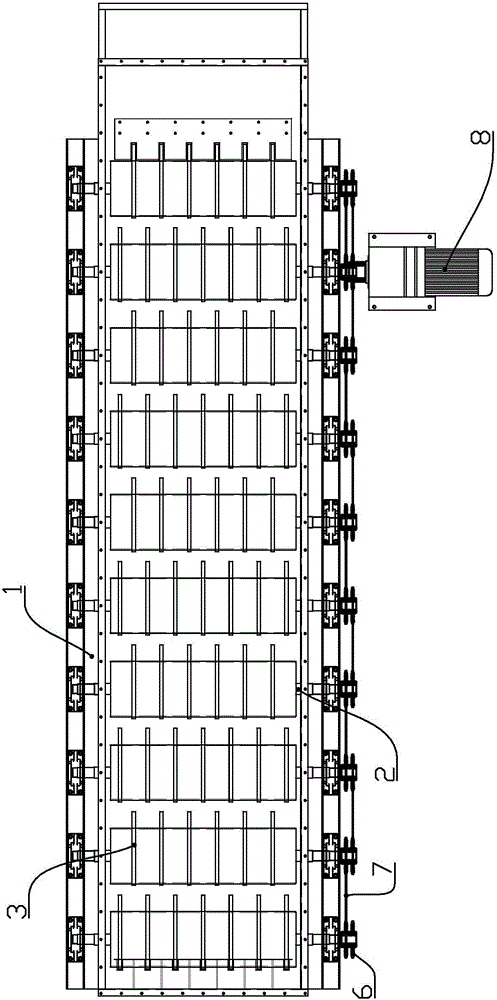

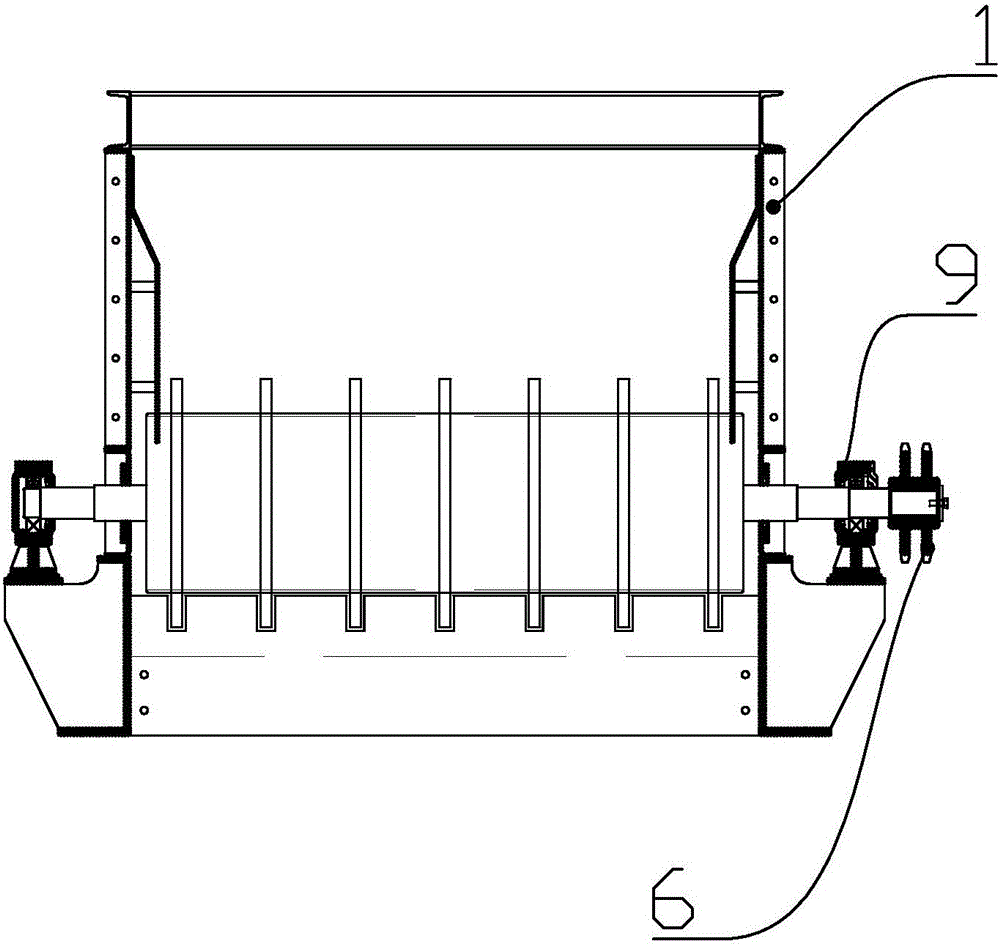

[0020] Such as figure 1 , 2 , 3, the present invention discloses a garbage butterfly screen, comprising a frame 1 with an upper opening, a plurality of screen shafts 2 parallel to each other are evenly installed in the frame 1, and the screen shafts 2 and The frame 1 is rotatably connected, and a plurality of sieve shafts 2 are interlocked with each other, and the outermost sieve shaft 2 is controlled to rotate by a driving mechanism. The sieve trays 3 on the adjacent sieve shafts 2 are arranged at intervals, the bottom of the frame 1 is provided with a bottom outlet 4, and one side of the frame 1 is provided with a side part above the axis of the sieve shaft 2. Outlet 5.

[0021] The driving mechanism drives multiple sieve shafts 2 to rotate synchronously. The sieve disc 3 on the sieve shaft 2 rotates synchronously with the sieve shaft 2. The garbage scattered on the sieve shaft 2 rotates with the sieve disc 3, and the smaller garbage passes through. The sieve holes betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com