Cold rolling method for internally threaded pipe

An internal threaded pipe and internal thread technology, applied in threaded products, metal rolling, metal rolling and other directions, can solve the problem of low precision and achieve the effect of normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] This specific embodiment is only an explanation of the present invention, but not a limitation of the present invention. Any changes made by those skilled in the art after reading the description of the present invention, as long as they are within the scope of the claims, will be protected by the patent law.

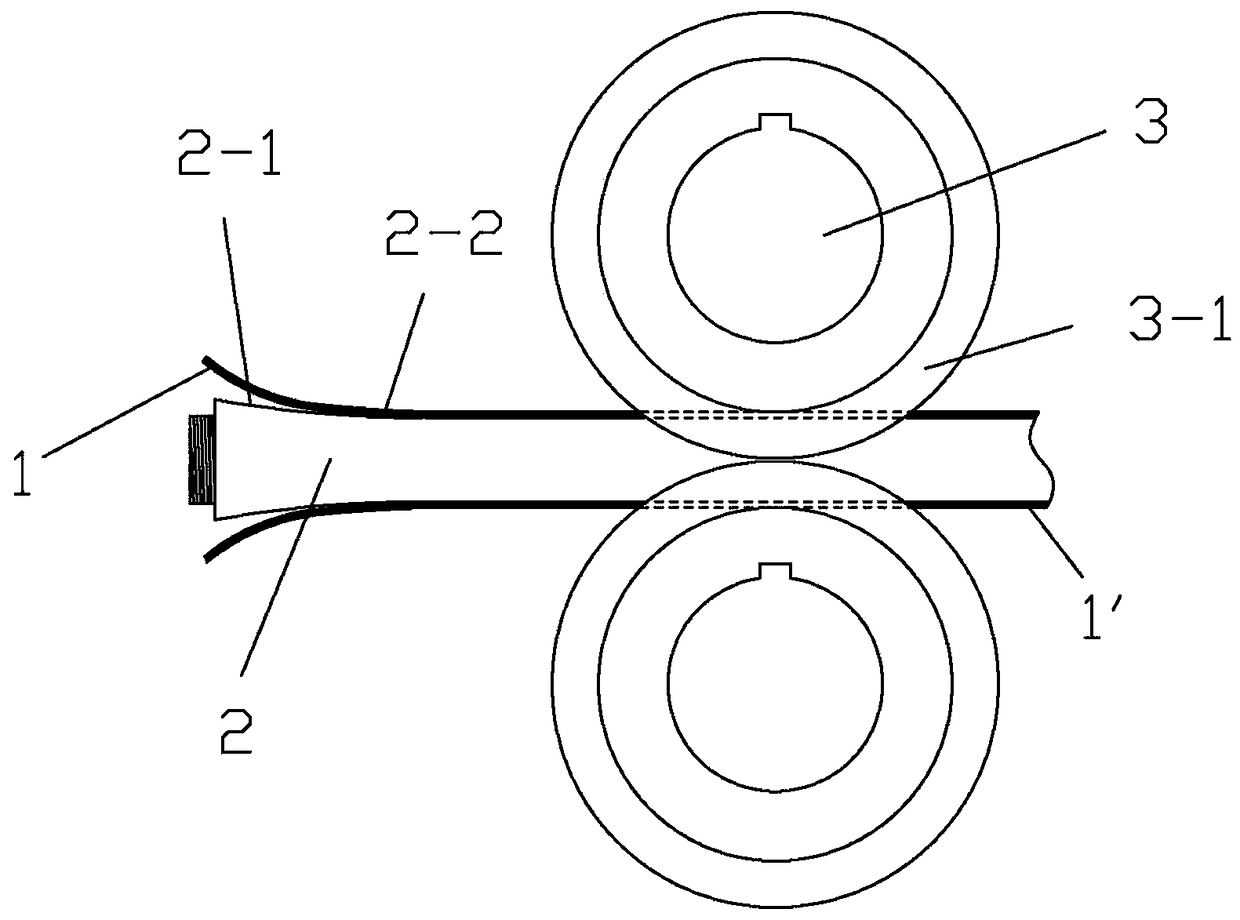

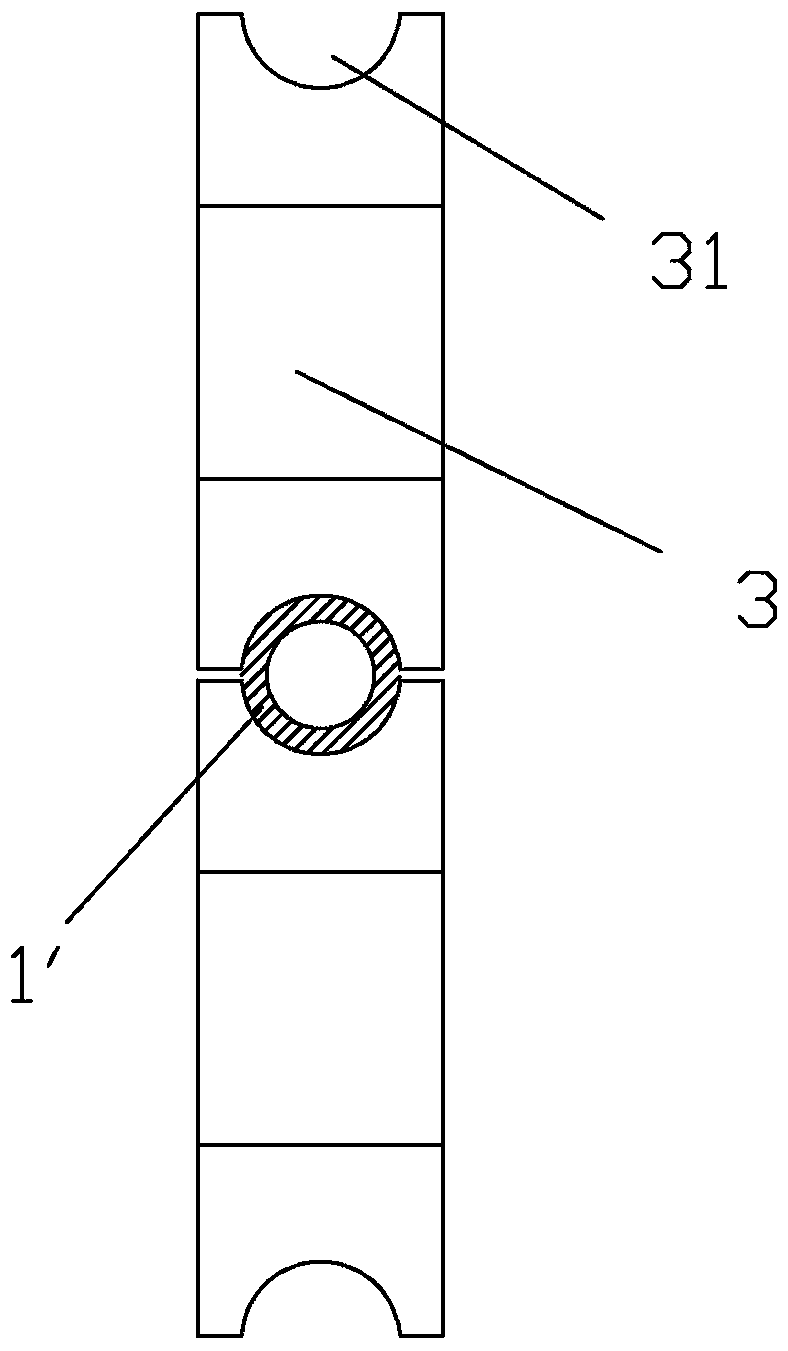

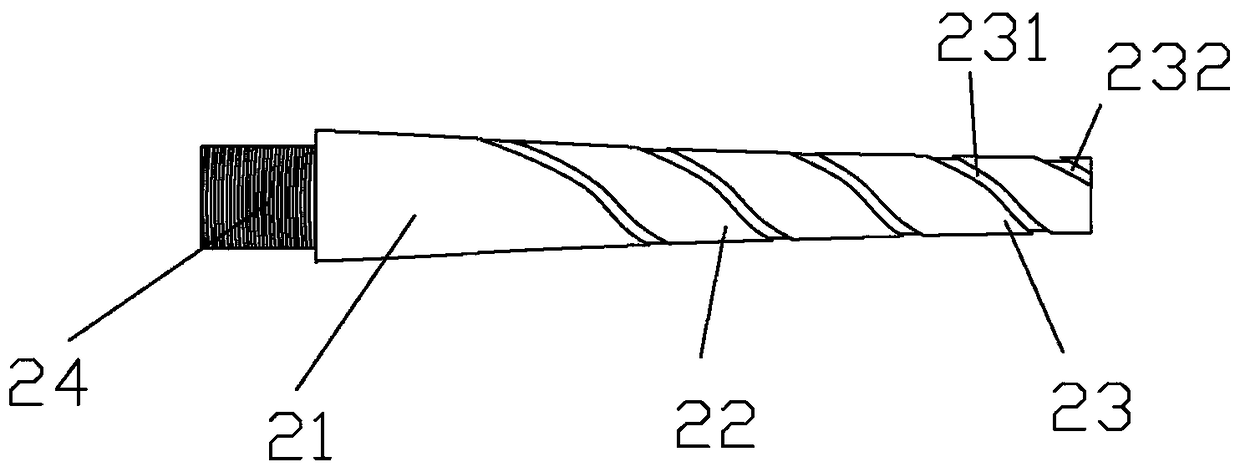

[0030] Such as figure 1 and 2 As shown, this figure 2 shows the cold rolling method of the internally threaded pipe. In the figure, 1 is an empty pipe, and 1' is an internally threaded pipe formed by the empty pipe 1 after being rolled by a mold. The mold includes a mandrel 2 and an outer mold 3. The mandrel 2 is lined in the waste pipe 1, and the outer mold 3 includes an upper mold and a lower mold, and the upper mold and the lower mold are paired, and the pipe is in the ring groove 3-1 of the upper mold and the lower mold. The specific method is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com