A fully automatic rotary screen printing machine patch heating table

A technology for heating tables and printing machines, which can be applied to screen printing machines, printing machines, rotary printing machines, etc., and can solve problems such as unfavorable fabric adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

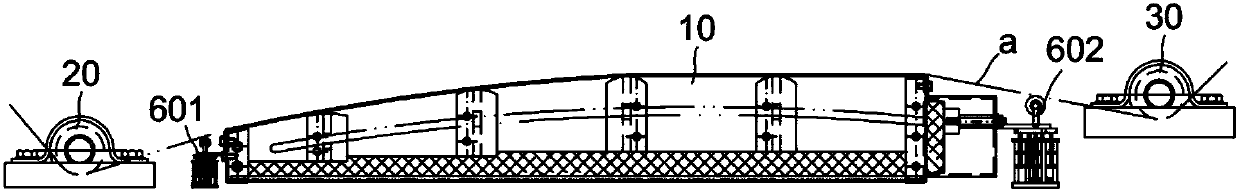

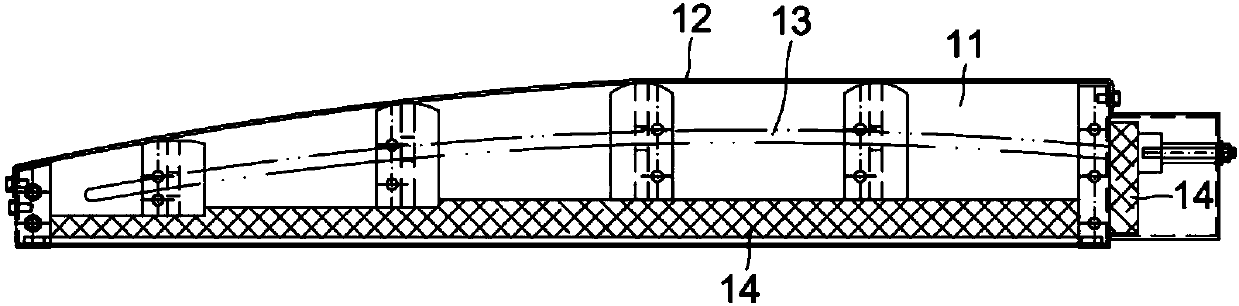

[0025] combine figure 1 , figure 2 , a fully automatic rotary screen printing machine pasting cloth heating table, comprising a heating table 10, a leading guide roller 20 positioned at the front end of the heating table, a rear guide roller 30 positioned at the rear end of the heating table; the heating table includes a frame 11, The arc-shaped plate 12 installed on the top of the frame, the thermoelectric tube 13 installed in the frame and below the arc-shaped plate. The frame 11 is paved with heat insulating material 14 , and the heat insulating material is located around the thermoelectric tube 13 . The number of the thermoelectric tubes 13 is twelve, and the twelve thermoelectric tubes are evenly arranged from the center of the frame 11 to the left and right sides, and the thermoelectric tubes are arc-shaped.

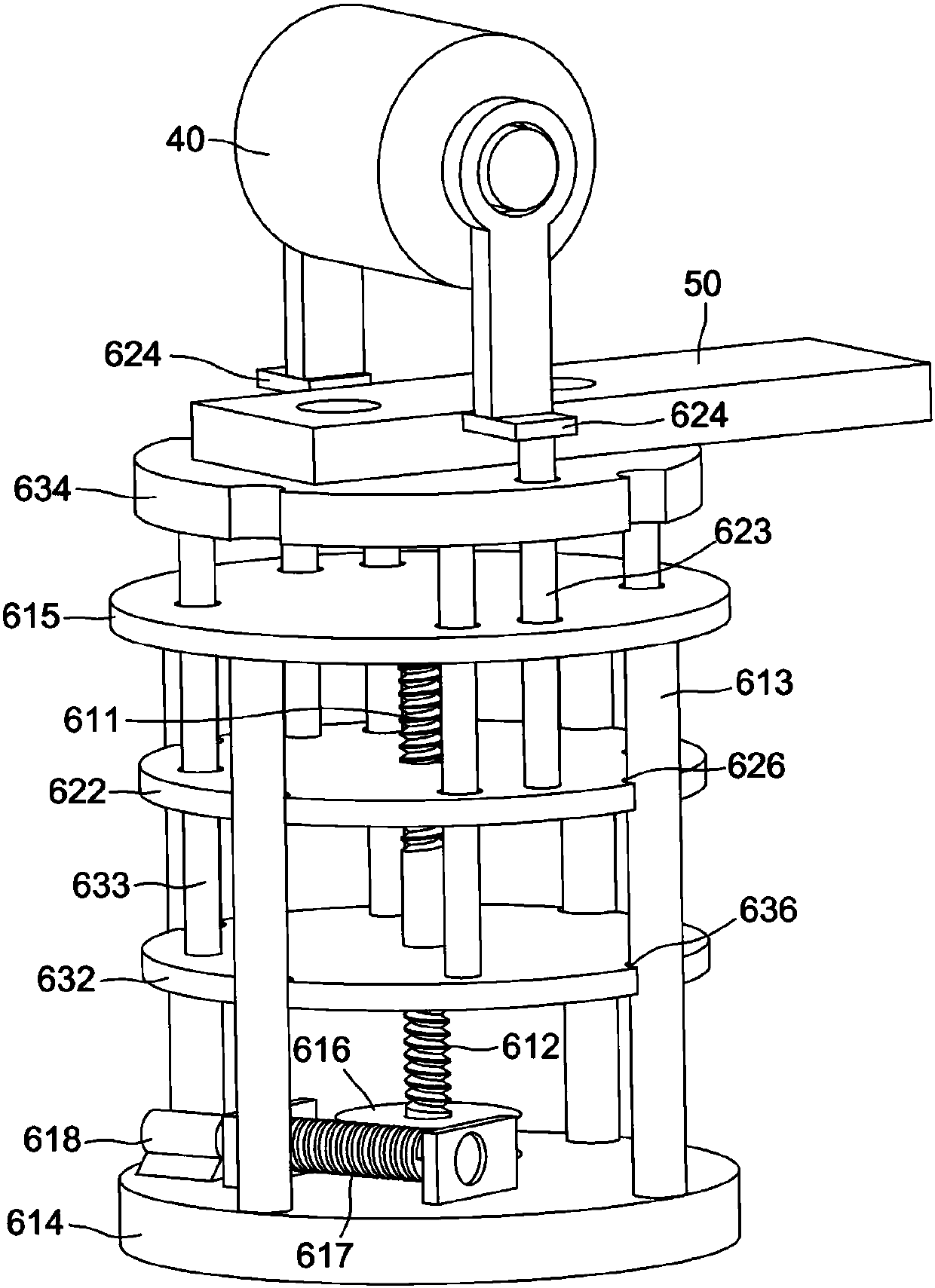

[0026] combine figure 1 , image 3 , the front end of the heating platform 10 is provided with a first lifting mechanism 601, and the rear end of the heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com