Iron core transport method and iron core transport device for on-site assembled transformer

An on-site assembly and transformer technology, applied in the field of transformer manufacturing, can solve the problems of high transportation cost, increase the on-site iron core assembly process, complex process, etc., and achieve the effect of reducing transportation weight, meeting transportation restrictions, and reducing assembly processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

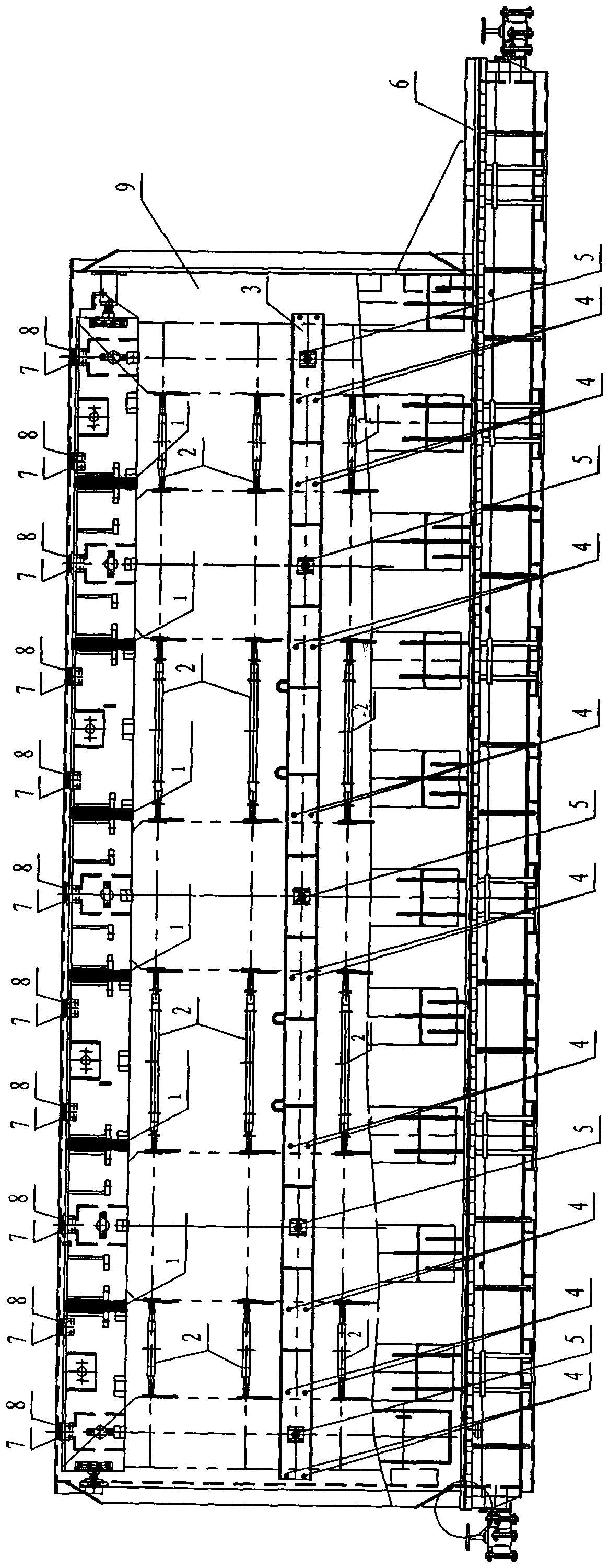

[0059] This embodiment provides a method for transporting an iron core of an on-site assembled transformer, and the on-site assembled transformer is specifically an on-site assembled transformer of 500 kV or above. The iron core of the field-assembled transformer in this embodiment is specifically a three-phase five-column iron core.

[0060] The iron core transportation method of the field-assembled transformer in this embodiment includes the following steps:

[0061] Step 1: Remove the upper iron yoke, the upper beam of the iron core and the coil assembly part of the iron core of the on-site assembled transformer to be transported.

[0062] In this embodiment, the weight of the undisassembled iron core in the on-site assembled transformer can satisfy the existing transportation weight conditions and the hoisting weight allowable conditions of the on-site factory building.

[0063] Among them, the upper iron yoke, the upper beam of the iron core and the coil assembly part wi...

Embodiment 2

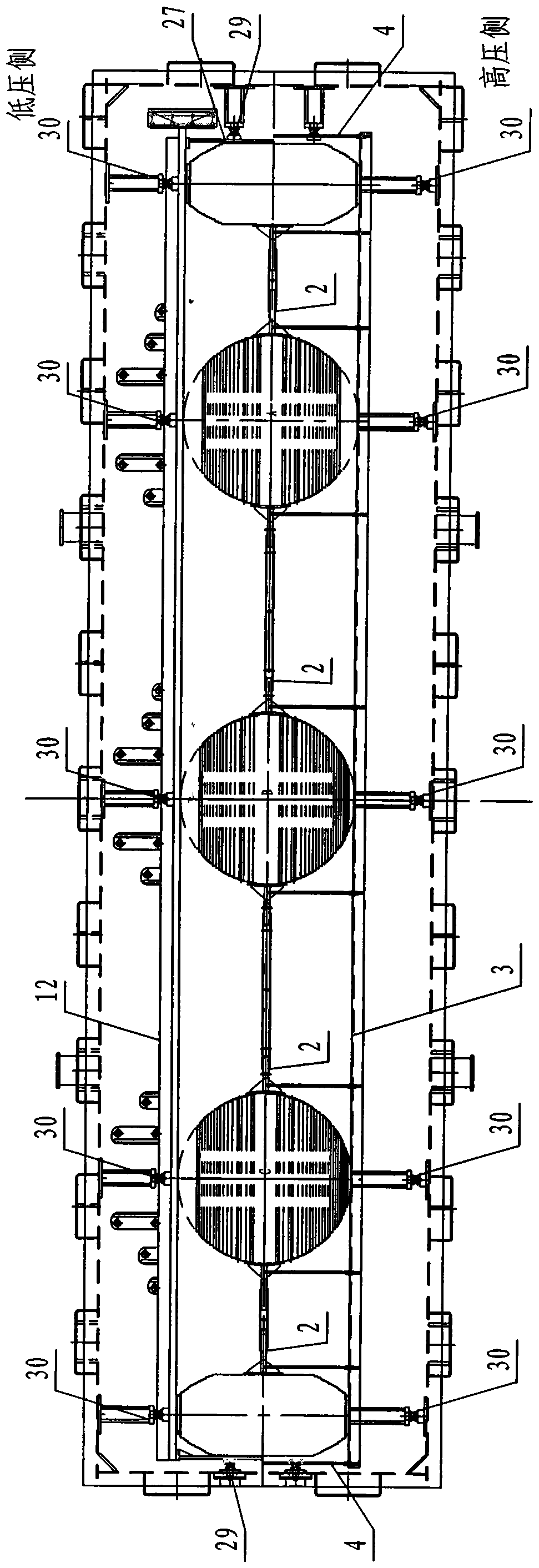

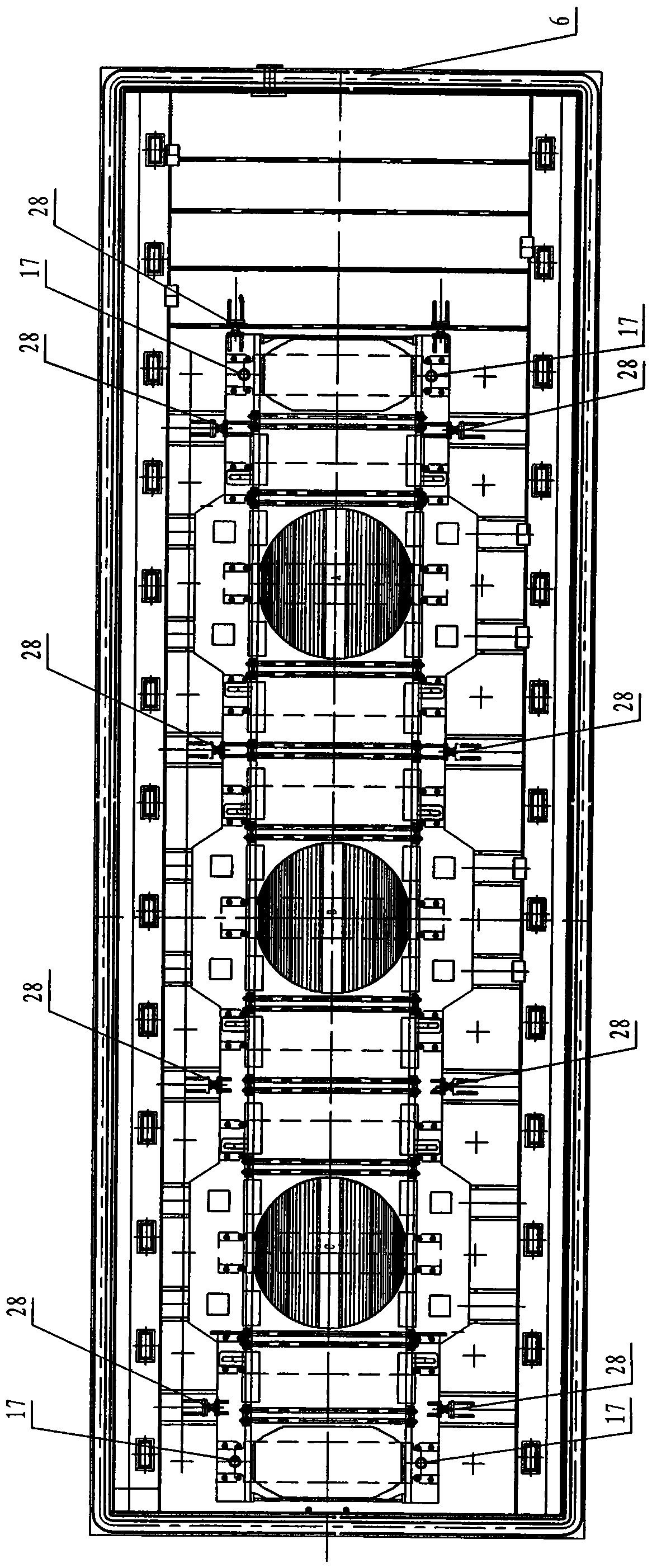

[0112] This implementation provides an iron core transportation device for on-site assembly of transformers, the device includes a temporary iron core upper section transportation box and a transformer body lower section fuel tank, the temporary iron core upper section transportation box includes a box cover and a box wall connected to the box cover,

[0113] The temporary iron core upper section transport box is arranged on the lower fuel section of the transformer body and is connected with the lower fuel section of the transformer body to form a transport box. The transport box can accommodate and dismantle the upper iron yoke, the iron core upper beam and the coil assembly. Part of the iron core, the iron core from which the upper iron yoke, the upper beam of the iron core and the coil assembly part are removed is a non-disassembled iron core.

[0114] Preferably, the device further includes a temporary upper beam 10 and a spacer 8 .

[0115] The temporary upper beam 10 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com