Biomass gasifying machine

A biomass and gasification agent technology, applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of no practicality and promotion value, poor continuity and stability, and insufficient fuel burnout, etc., to achieve simple structure, work Stable and continuous effect with long gas production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

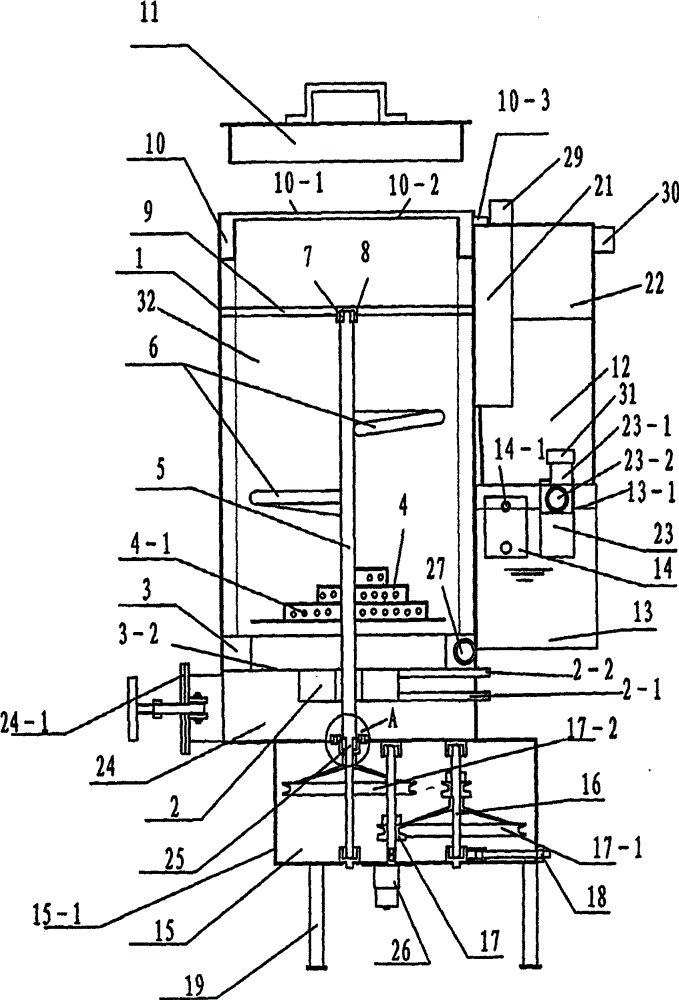

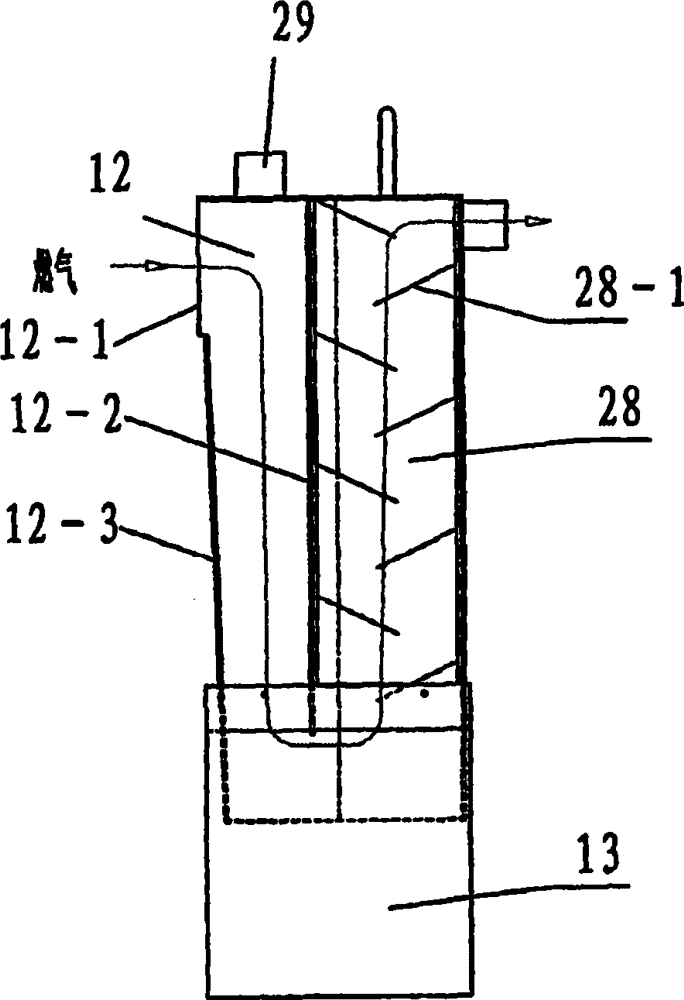

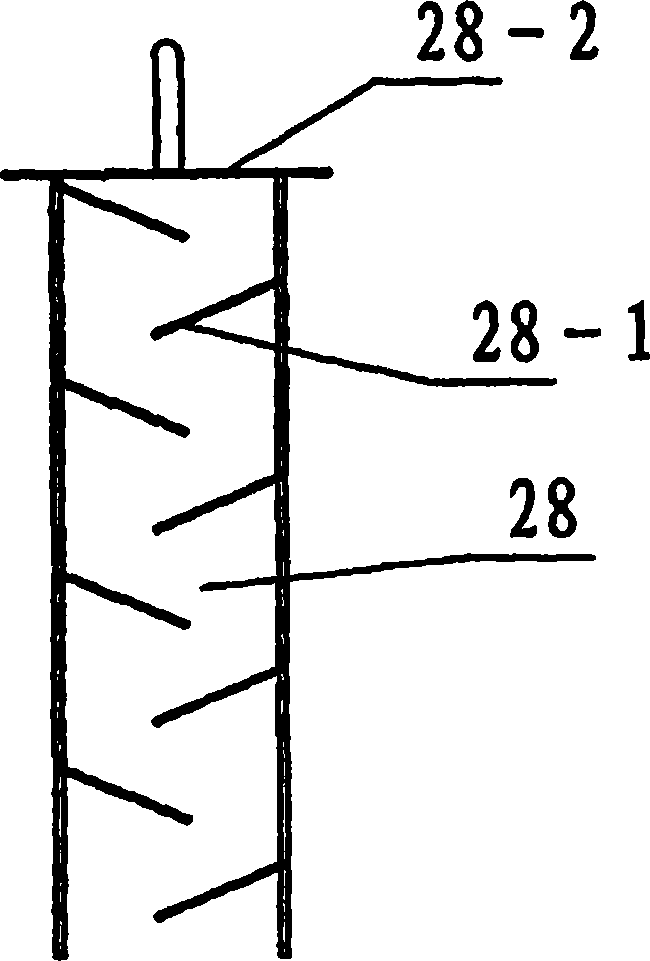

[0021] Such as Figures 1 to 5 As shown, a biomass gasifier includes a furnace body 1 with a furnace cover 11, wherein the annular gasification agent preheating chamber 3 at the lower end of the furnace body 1 divides its inner chamber into upper and lower chambers, namely The upper chamber is the furnace 32, the lower chamber is the ash chamber 24, the lower end of the furnace body 1 is provided with a gearbox 15, the gearbox 15 includes a casing 15-1 and a motor 26, and the motor 26 is inserted into the output shaft of the casing 15-1 for loading Belt pulley 17 is arranged, and this belt pulley 17 is connected with belt pulley 17-1 on the belt pulley rotating shaft 16, and belt pulley 17-1 on the belt pulley rotating shaft 16 is connected with belt pulley 17-2 on the center shaft 5, and belt tightness adjustment is also connected on the belt pulley rotating shaft 16 Rod 18, that is, the output shaft of the gearbox is the central axis 5 of the furnace body; the central axis 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com