High Stress Induced Blasting Blasting Method in Deep Stope

A high-stress, deep technology, applied in blasting, surface mining, underground mining, etc., can solve problems such as poor application effect, lack of theoretical basis, and inability to adapt to the complex and changeable characteristics of high-stress fields in deep ore and rocks, reducing The effect of small explosive unit consumption, safe and efficient recovery, and improvement of mine production economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 High stress-induced blasting ore collapse method in deep stope

[0041] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

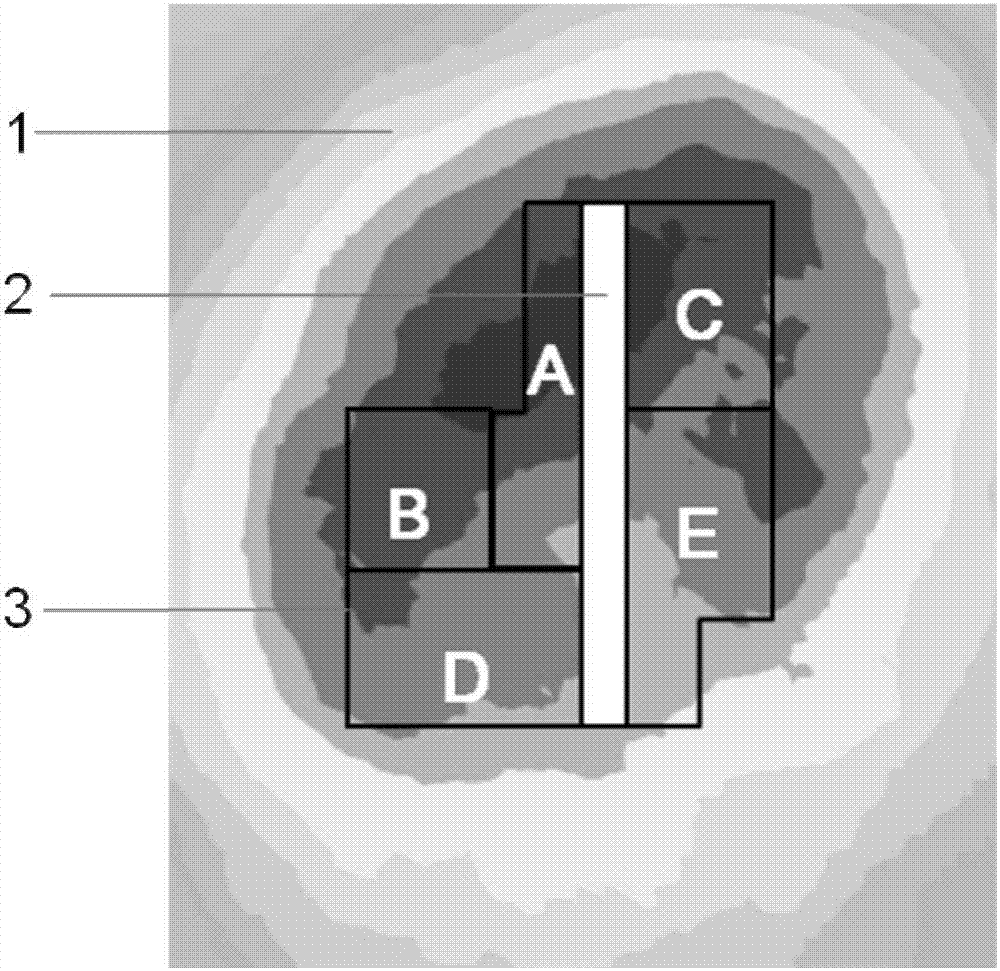

[0042] refer to figure 1 , the high stress induced blasting ore collapse method in the deep stope of the copper-zinc mine in this embodiment, the specific steps are as follows:

[0043] 1) First, microseismic sensors are arranged in the surrounding space of the selected deep stope to collect microseismic event signals.

[0044] Deep stope mining operation

[0045] 2) The first step of mining: in the process of mining, the bottom cutting project is taken as the first step of mining.

[0046] 3) After the stope bottom cutting project (cutting groove 2) is completed and the distribution of ore stress field 1 is stable, the signal collected by the microseismic monitoring system is analyzed and processed to obtain the stress field cloud after deep stope cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com