Impact device and control terminal

A technology for controlling terminals and percussion devices, which is applied in the direction of instruments, analysis materials, ultrasonic/sonic/infrasonic generation, etc., which can solve the problems of heavy workload, cumbersome process, and long detection time of detection personnel, and achieve shortened detection time and improved Detection efficiency, the effect of simplifying the detection process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

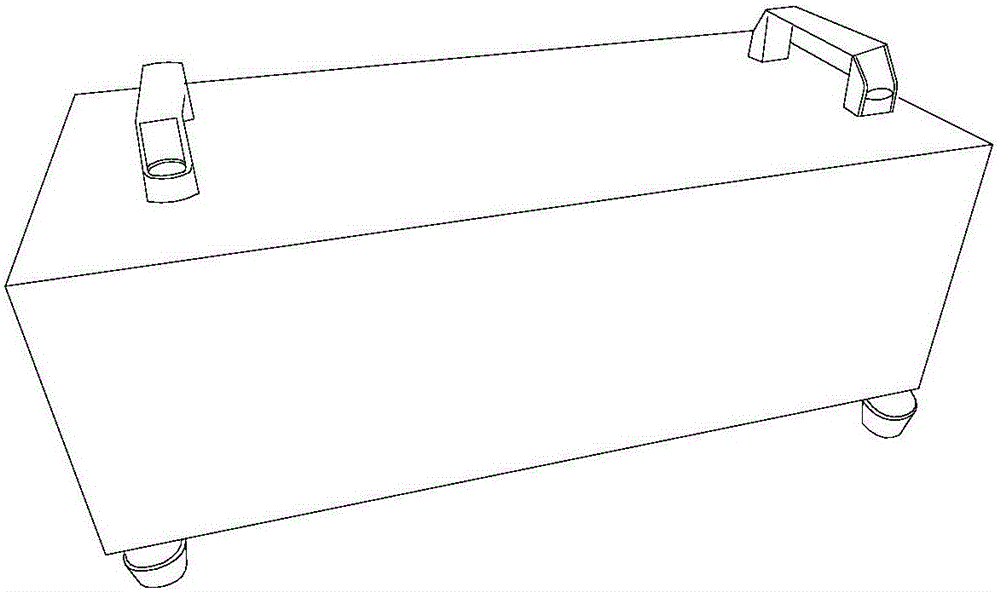

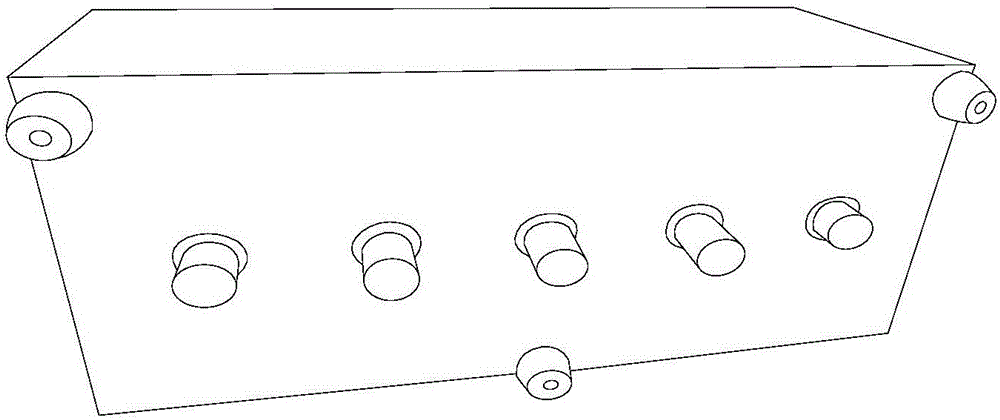

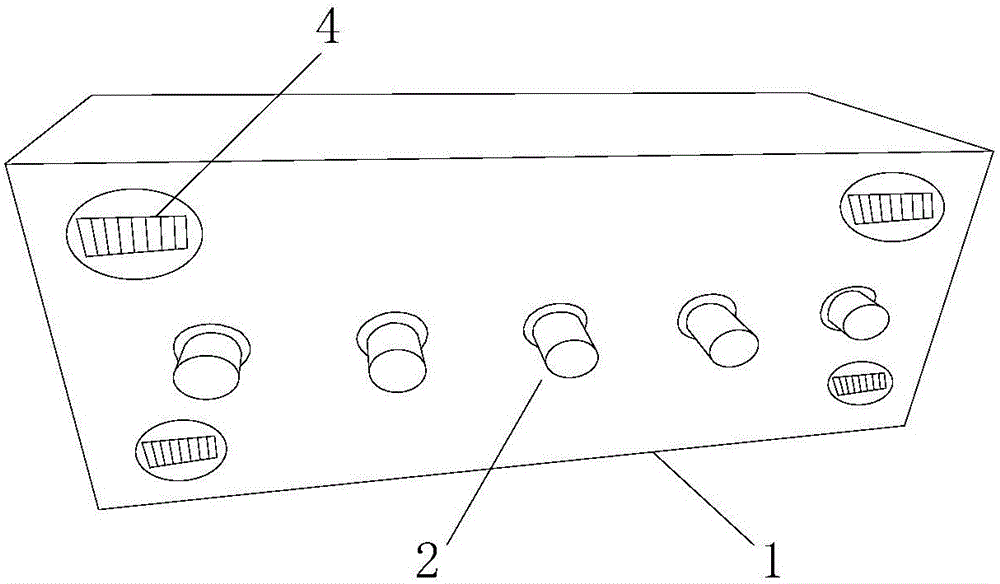

[0037] This embodiment provides a striker, such as Figure 3A As shown, it includes chassis 1, hammer 2 and power connection terminal. The power connection end is used to connect to a power supply, and one end of the cable can be connected to the power connection end and the other end can be connected to an AC power socket, or the power connection end can be connected to a battery. Striking hammer 2 is positioned at the bottom of cabinet 1, is used for hitting ground. Inside the cabinet 1 there is a first driving device 3 for driving the hammer 2 to hit the ground. The power connection terminal is connected with a power source and supplies power to the first driving device 3 .

[0038] The striker also includes a walking device 4, a second driving device 5, a first wireless communication unit 6 and a main controller 7, such as Figure 3B shown.

[0039] The running device 4 is located at the bottom of the chassis 1 and is used to drive the chassis 1 to walk.

[0040] The se...

Embodiment 2

[0050] This embodiment provides a control terminal, such as Figure 4A As shown, it includes a striker control interface 41 and a second wireless communication unit 42 .

[0051] The percussion device control interface 41 is used for receiving the control command of the percussion device described in Embodiment 1. When the inspector operates the control terminal to control the percussion device, the control command is input through the percussion device control interface.

[0052] The second wireless communication unit 42 is connected to the percussion device control interface, and is used for transmitting control commands to the percussion device.

[0053] The above-mentioned control terminal receives the control command of the striker through the striker control interface; transmits the control command to the striker through the second wireless communication unit. Using the control terminal, the inspector can conveniently control the walk of the striker.

[0054] As a pref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com