Fluorescent lamp test frame with flat cable grooves

A technology of fluorescent lamps and test racks, which is applied in the direction of the measuring device casing, etc., can solve the problems of confusing wire connections, restless workers, and low work efficiency, and achieves the effects of convenient operation, large up and down space, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

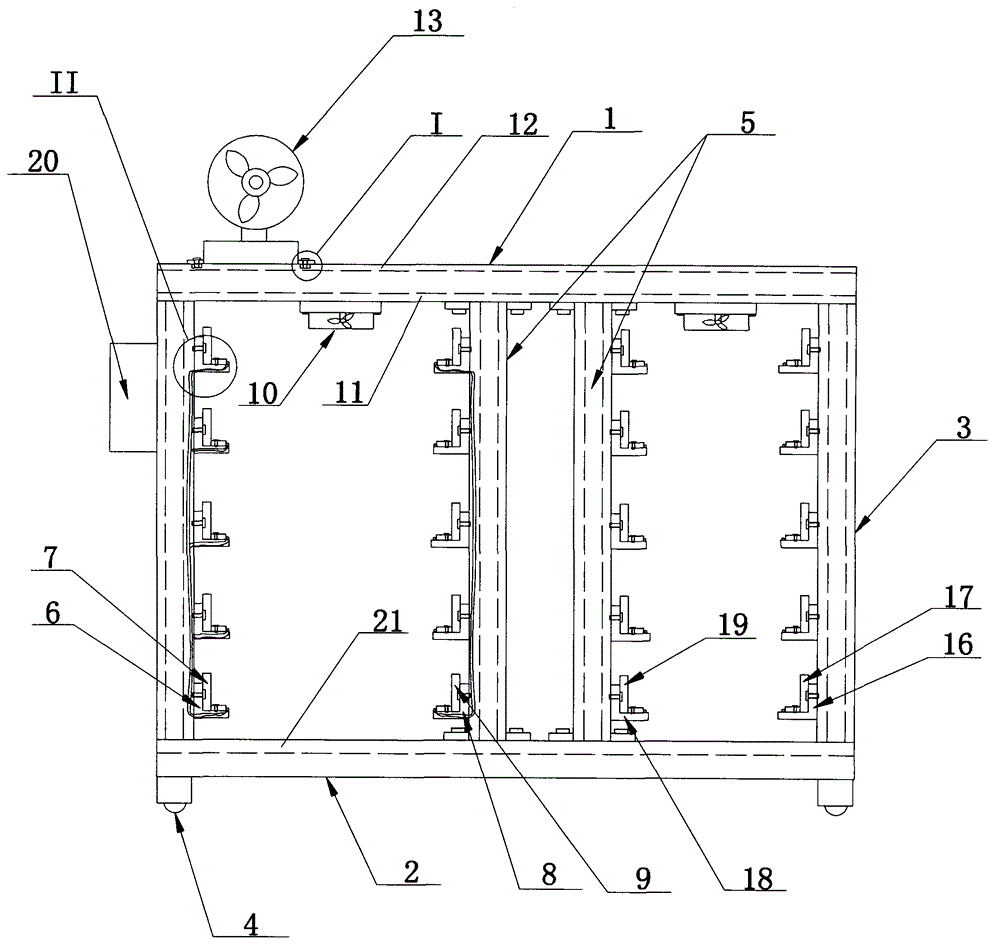

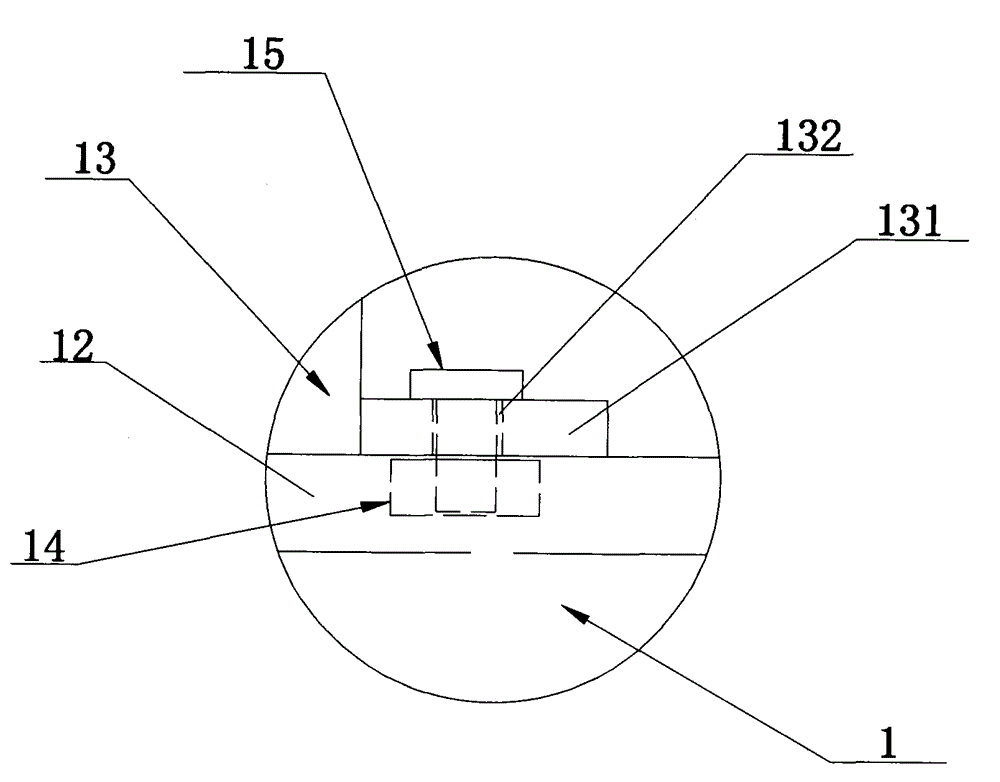

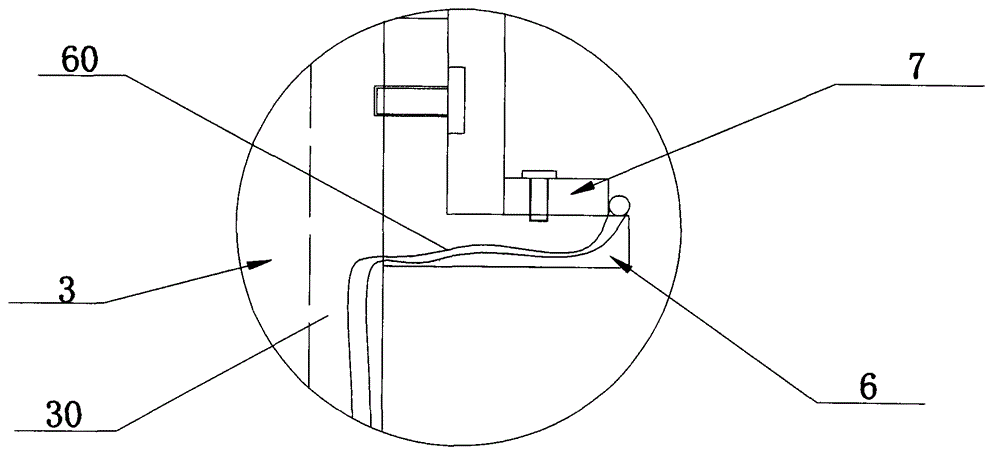

[0017] see figure 1 , figure 2 , image 3 and Figure 4 , the present invention discloses a fluorescent lamp test frame with a wiring trough, which includes a bracket, which is a rectangular body constructed of profiles, including an upper rectangular frame 1, a lower rectangular frame 2, and four fixed columns 3. The lower rectangular frame A pulley 4 is installed at the bottom of the frame 2, an upper groove rail 11 is provided in the middle of the lower end faces of the two long sides of the upper rectangular frame 1, and a lower groove rail 21 is arranged in the middle of the upper end faces of the two long sides of the lower rectangular frame 2. Four sliding uprights 5 are arranged between the rail 11 and the lower grooved rail 21, and several first angle steels 6 are evenly arranged between the two fixed uprights 3 at the left end of the lower rectangular frame 2 from bottom to top, each first Several first lamp holders 7 are detachably arranged on the angle steel 6,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap