Defect-state structure acoustic metamaterial plate

A technology of acoustic metamaterials and defect states, applied in the field of acoustic metamaterials, can solve unrealistic and unsatisfactory low-frequency vibration and noise reduction problems, and achieve the effects of easy layout, easy batch processing, and flexible plane size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

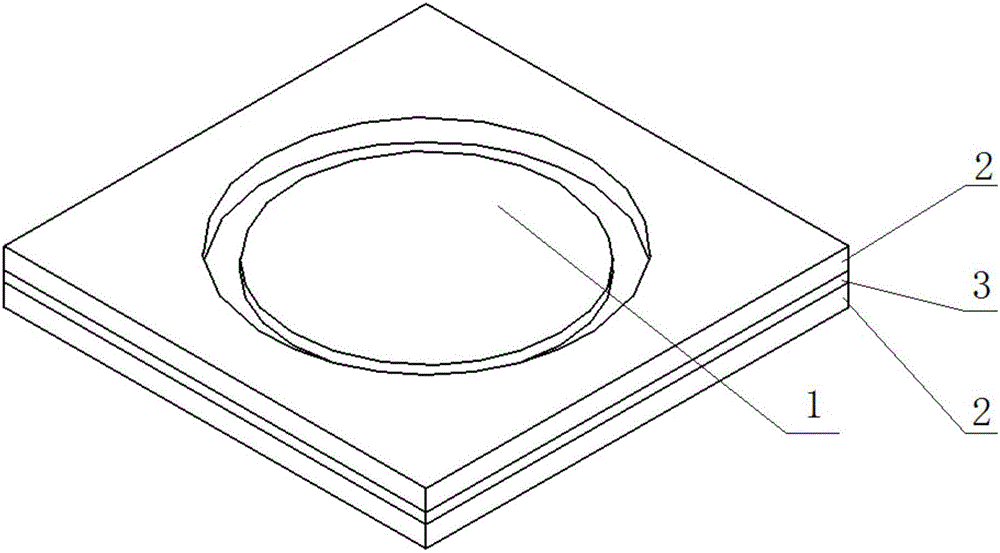

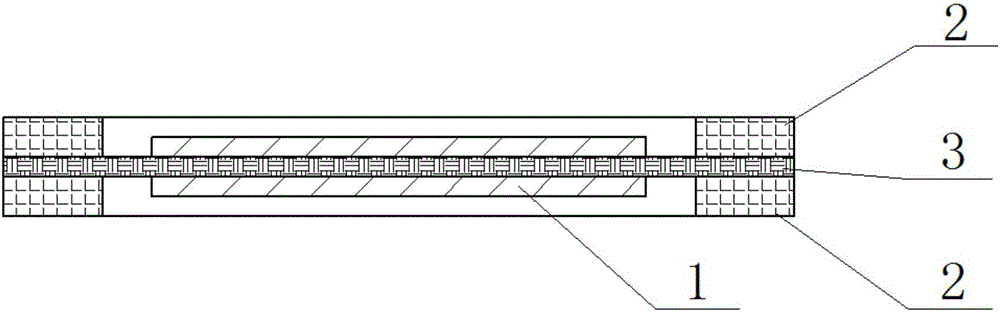

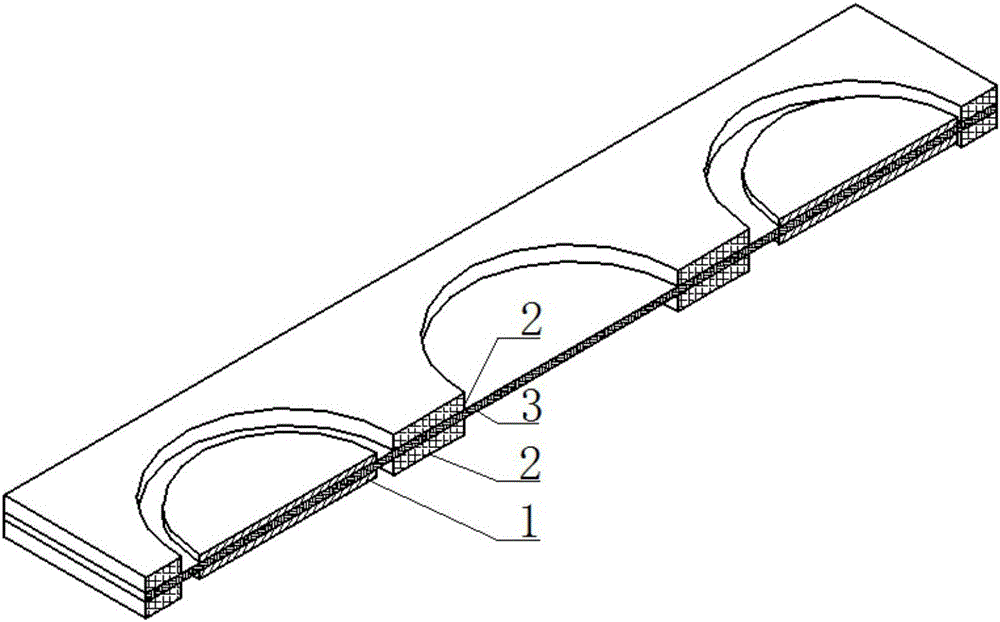

[0022] Such as Figure 1-4 As shown, the defect-state structural acoustic metamaterial plate of the present invention includes an elastic film 3 , two composite material plates 2 and several mass sheets 1 . Two composite material boards 2 are bonded to the upper and lower sides of the elastic film 3 respectively. The composite material board 2 is provided with periodically arranged openings, and several mass sheets 1 are respectively bonded to the elastic film 3 at the openings. The quality sheets 1 Has defect state structure 4 in the distribution. The defect state structure 4 is for the arrangement of several mass slices as a whole, including at least one of mass slice 1 quality unevenness, mass slice 1 eccentricity, or mass slice 1 absence.

[0023] It should be noted that for the periodically arranged openings on the composite material plate 2 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com