Composite damping plate made of low-frequency damping metamaterial

A technology of composite damping and metamaterials, applied in the direction of rubber layered products, layered products, chemical instruments and methods, etc., can solve the problem of space conditions or cost prohibition, failure to meet the requirements of low frequency reduction, vibration isolation, and bulky structure and other issues, to achieve the effect of easy batch processing, easy layout, and flexible plane size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

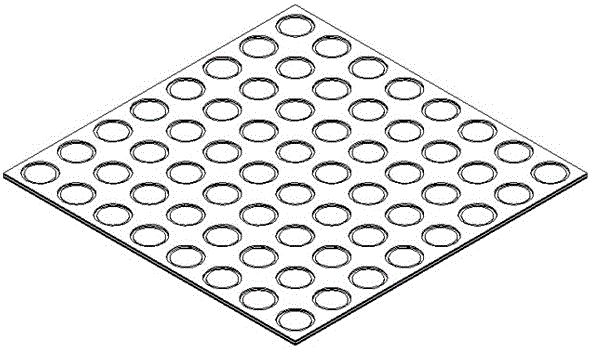

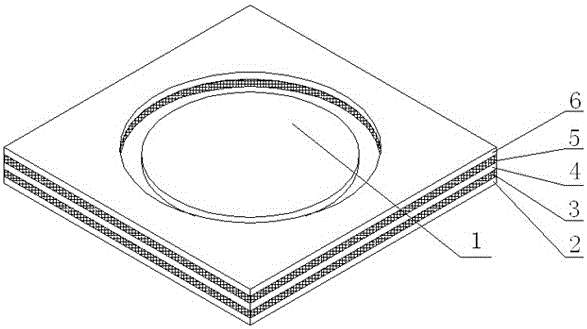

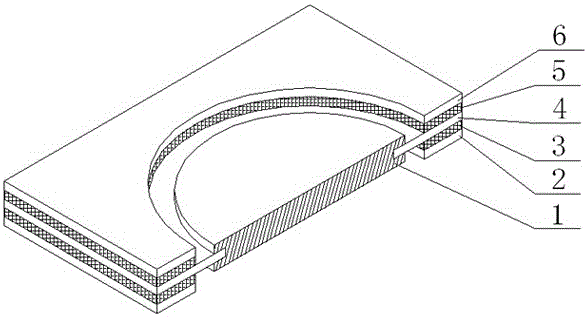

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a low-frequency vibration-absorbing supermaterial composite damping plate of the present invention includes a plate body, and the plate body is composed of a first upper composite layer 5, an intermediate layer 4 and a first lower composite layer 2, and the first Both the upper composite layer 5 and the first lower composite layer 2 are fiber composite material layers, the middle layer 4 is a viscoelastic film damping layer, and between the first upper composite layer 5 and the middle layer 4 and the first lower composite layer 2 and the middle layer 4 are bonded by viscous fluid damping glue; an array of holes is opened on the board body, and a quality sheet 1 is installed in each hole, and the quality sheet 1 is embedded in the The viscoelastic thin film damping layer....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com