A continuous dissolver for spent fuel elements with a screw pusher device

A pusher and spent fuel technology, applied in the fields of reactor fuel elements, climate sustainability, reactors, etc., can solve the problems of huge plant facilities, complex technology and equipment, and high construction, operation and maintenance costs, and improve the flexibility of use. performance, ease of maintenance or replacement, and the effect of preventing the formation of foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

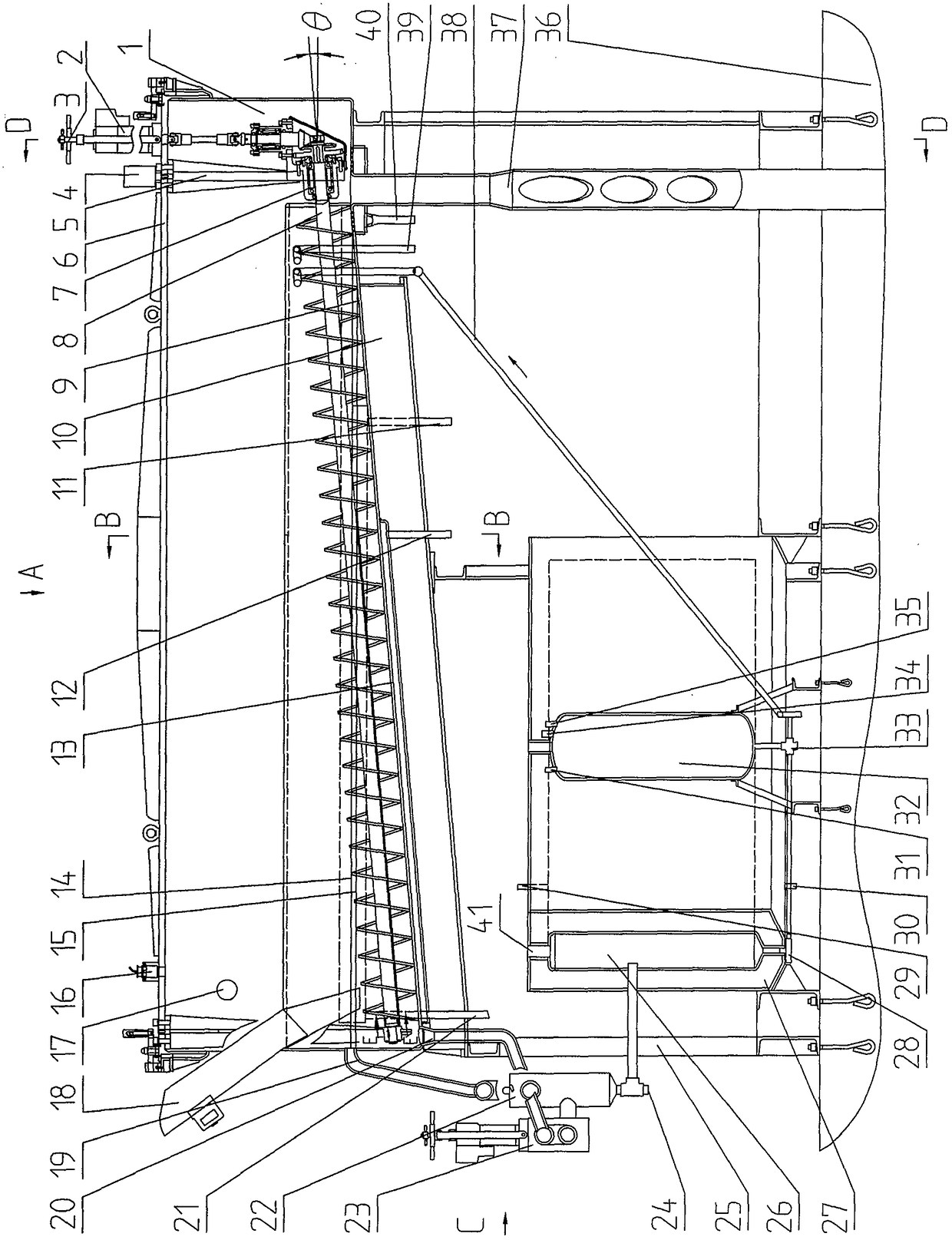

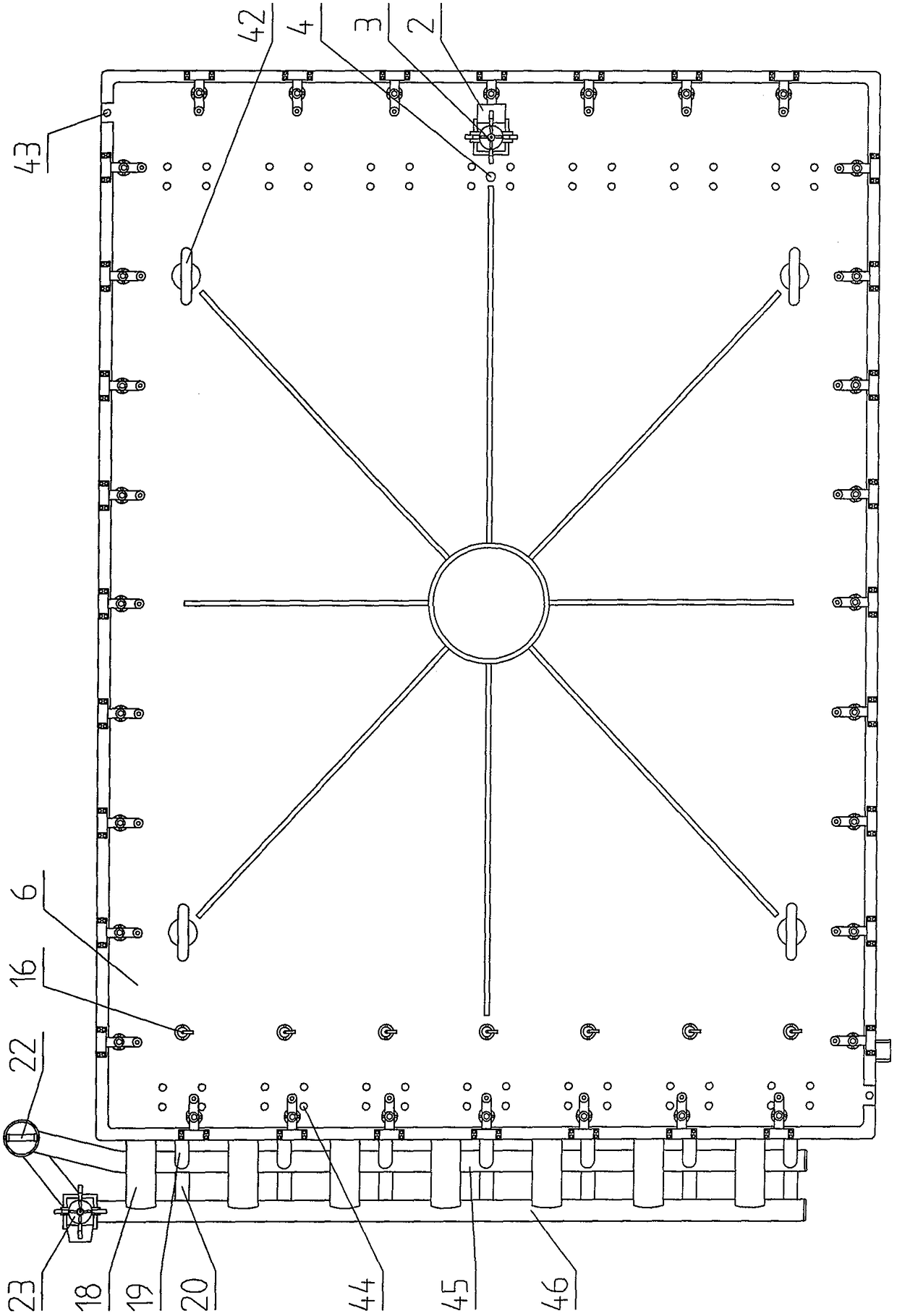

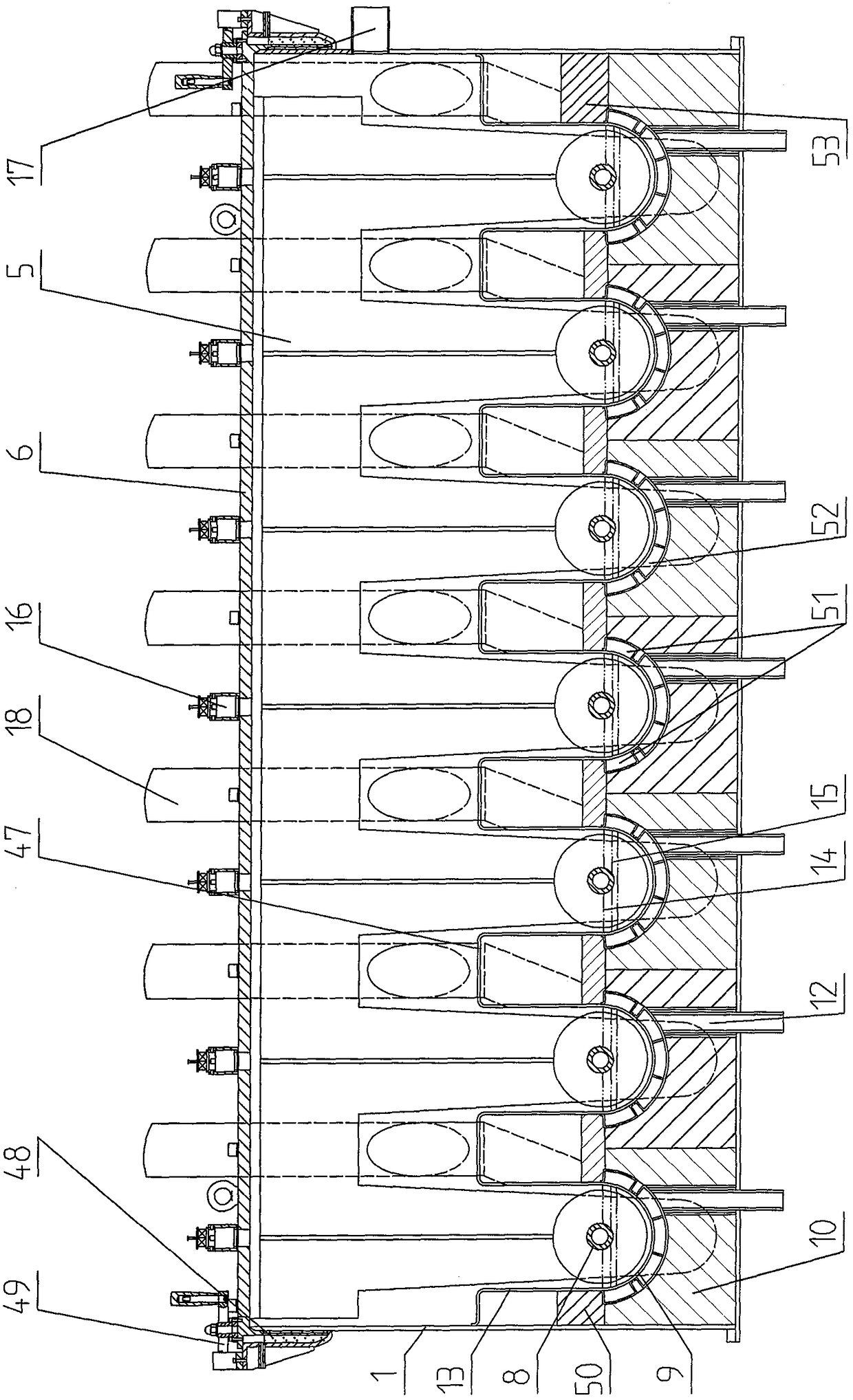

[0034] Such as Figure 1-8 Shown is a continuous dissolver for spent fuel elements with a screw pusher device, which includes a dissolution system, a dissolution circulation and filtration system, a waste cladding removal system, and a tank bottom fouling removal system.

[0035] Such as Figure 1-8 As shown, the dissolving system is provided with a rectangular tray dissolving tank 1 and a plurality of mutually separated long tanks 13 equidistantly distributed in parallel at the bottom, and each long tank 13 is provided with a screw shaft 8, the long tank 13 and the screw shaft 8 The axis and the horizontal plane form a certain inclination angle θ, and are lifted from the short-section feed end of the component to the discharge end; the dissolution cycle and filtration system are set under the dissolution tank 1; the waste cladding removal system is set under the high end of the sloping bottom of the dissolution tank 1 ; The bottom of the dissolution tank 1 is provided with a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap