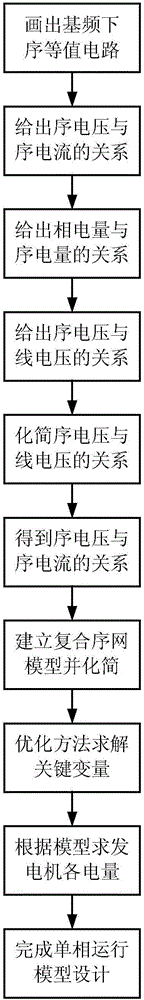

Design method for achieving single-phase operation of star-connection three-phase asynchronous generator

An asynchronous generator, three-phase asynchronous technology, applied in the direction of asynchronous generator control, control of generators, electrical components, etc., can solve the problems of small capacity of single-phase asynchronous generators, difficult to meet operating requirements, low efficiency, etc., to achieve the design The principle is scientific and reliable, the operation is flexible, and the application effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

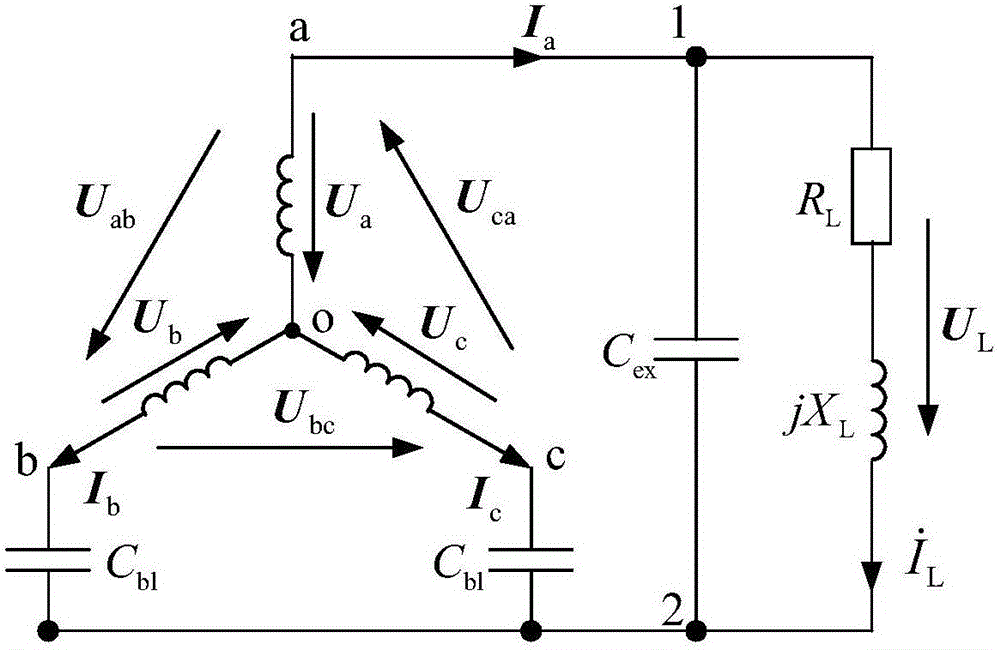

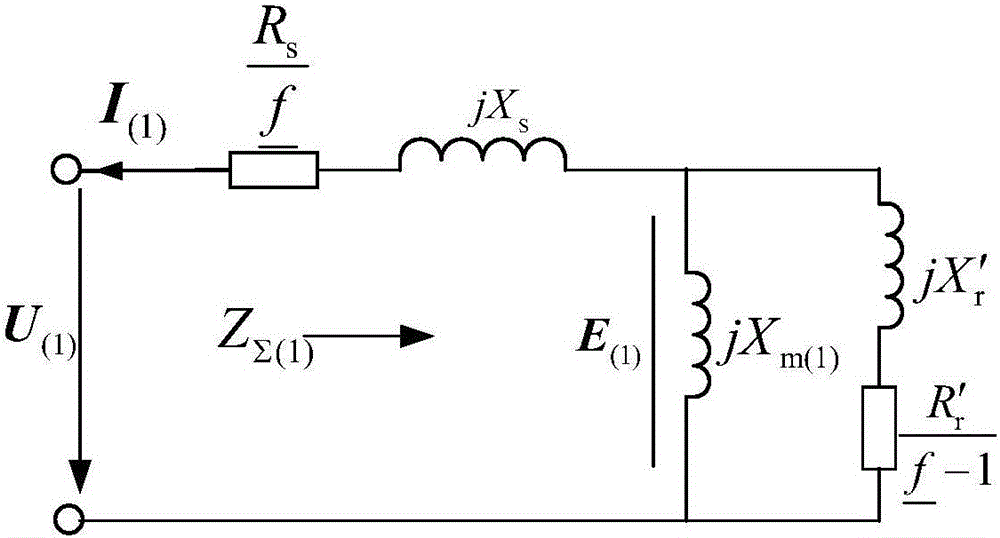

[0024] Example: First select a conventional star-connected three-phase asynchronous generator with a rated power P N 2.2kW, rated voltage U N 380V, rated current I N 5A, rated speed n N 1500r / min, rated frequency (base frequency) f N 50Hz, stator resistance R s 2.80Ω, rotor resistance (converted value) R r Is 3.20Ω, stator reactance X s Is 3.44Ω, rotor reactance (converted value) X r ′ Is 3.44Ω; the induced potential E at the base frequency (1) And positive sequence magnetizing reactance X m(1) The relationship is expressed as:

[0025] E ( 1 ) = 355.4 - 1.725 X m ( 1 ) , X m ( 1 ) 69.69 369.7 - 1.930 X m ( 1 ) , 69.69 ≤ X m ( 1 ) 99.76 422.6 - 2.460 X m ( 1 ) , 99.76 ≤ X m ( 1 ) 107.5 523.0 - 3.394 X m ( 1 ) , 107.5 ≤ X m ( 1 ) 154.1 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com