An in-situ self-calibrating temperature sensor device

A sensing device and in-situ technology, applied in thermometers, measuring devices, electrical devices, etc., can solve problems such as unfavorable real-time calibration and self-calibration, long calibration process time, loss of accuracy, etc., to achieve scientific and reliable design principles , Stable electrical performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

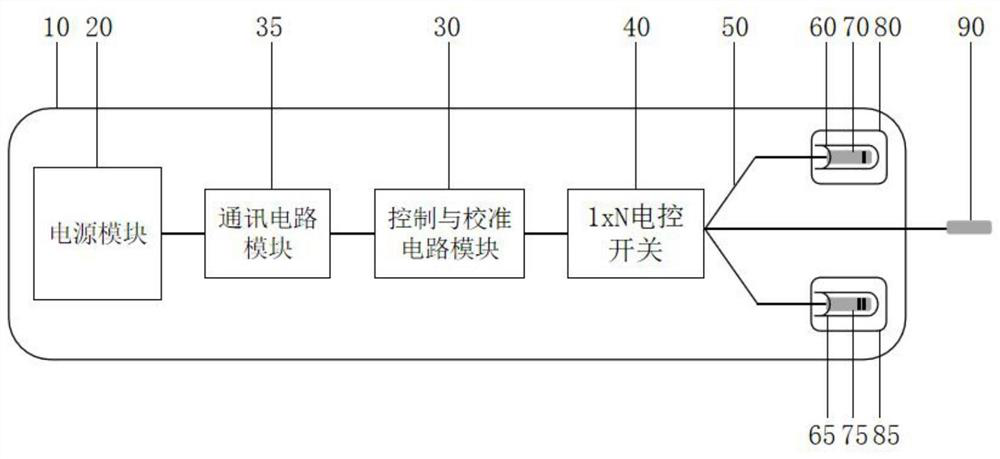

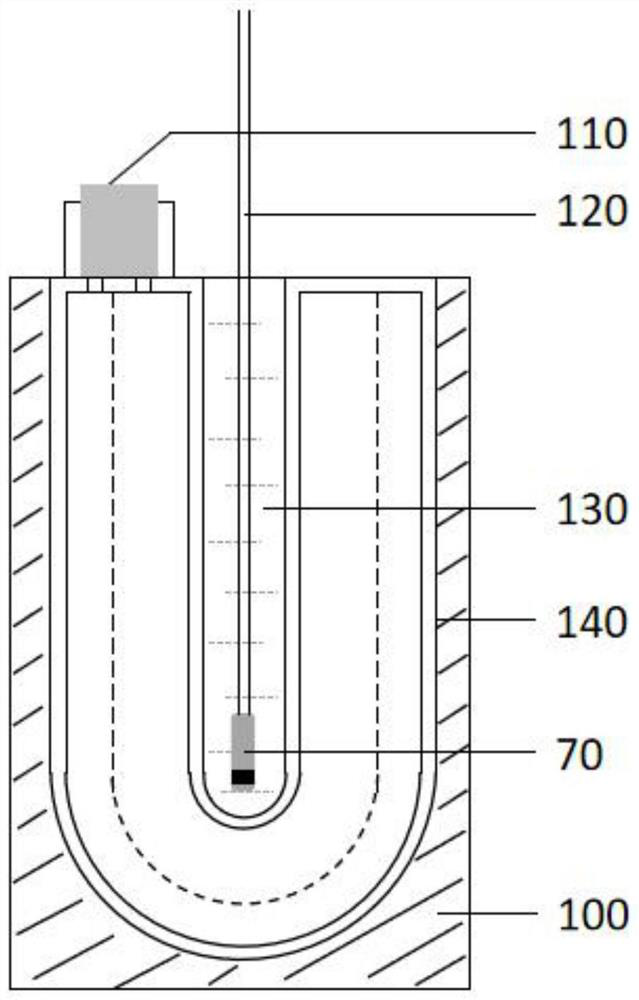

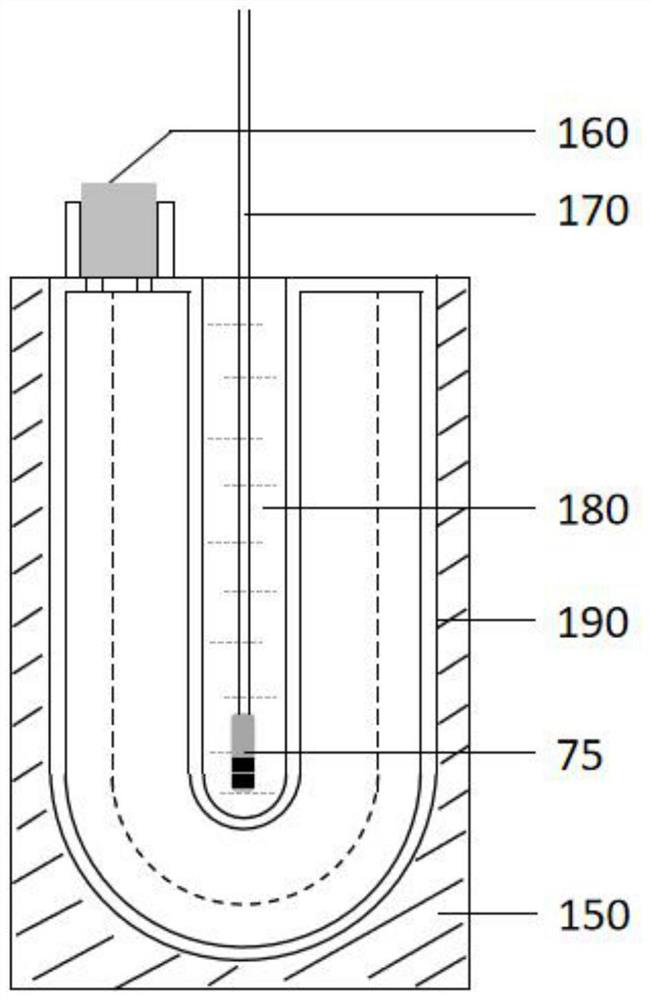

[0018] The main structure of the in-situ self-calibration temperature sensing device involved in this embodiment includes a packaging case 10, a power supply module 20, a control and calibration circuit module 30, a communication circuit module 35, a 1xN electric control switch 40, a wire 50, a micro water Triple point vial 60, miniature gallium triple point vial 65, miniature water temperature calibration sensing probe 70, miniature gallium temperature calibration sensing probe 75, integrated miniature water triple point vial device 80, integrated miniature gallium triple point Bottle device 85, temperature measurement sensor probe 90, first refrigerator 100, second refrigerator 150, first sealing plug 110, second sealing plug 160, first conducting wire 120, second conducting wire 170, first alcohol 130, the second alcohol 180, the first outer casing 140, and the second outer casing 190; each component is electrically connected and fixed in the packaging casing 10 with a water...

example example 2

[0024] The in-situ self-calibration temperature sensor prepared in this embodiment is applied to the measurement of the ambient temperature of seawater in the deep sea, and can in-situ calibrate the temperature drift caused by the sensor affected by the deep sea pressure. Its temperature parameters are stable and can achieve long-term stability of temperature measurement better than 1mK and above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com