A crushing and stirring type dough kneading device

A stirring and noodle maker technology, which is applied in home appliances, applications, kitchen utensils, etc., can solve the problems of inconvenient food processing, no general processing equipment, and inconvenient electricity use, so as to improve convenience and scientific design principles Reliable, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

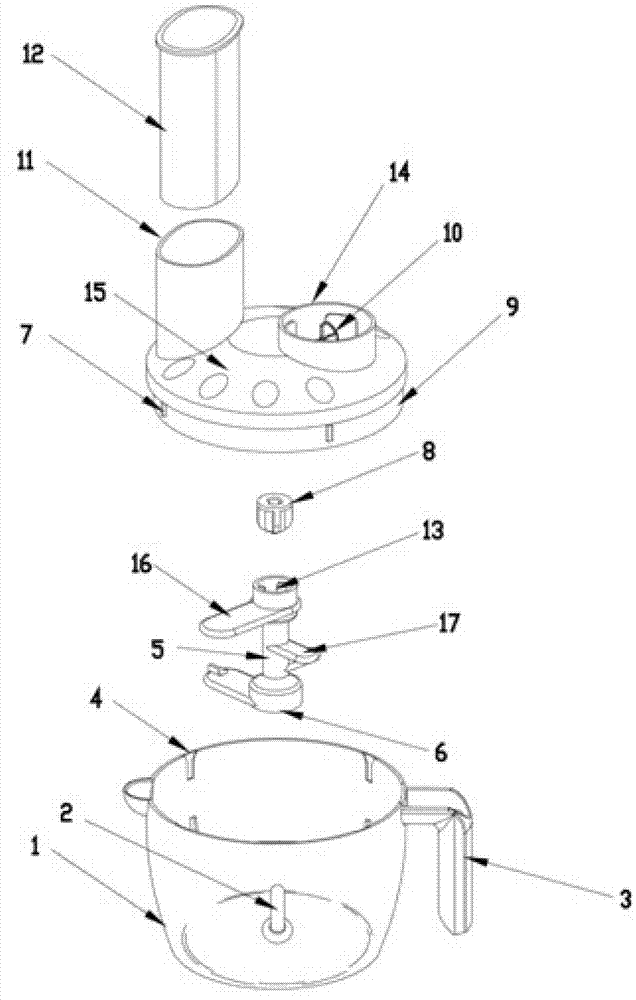

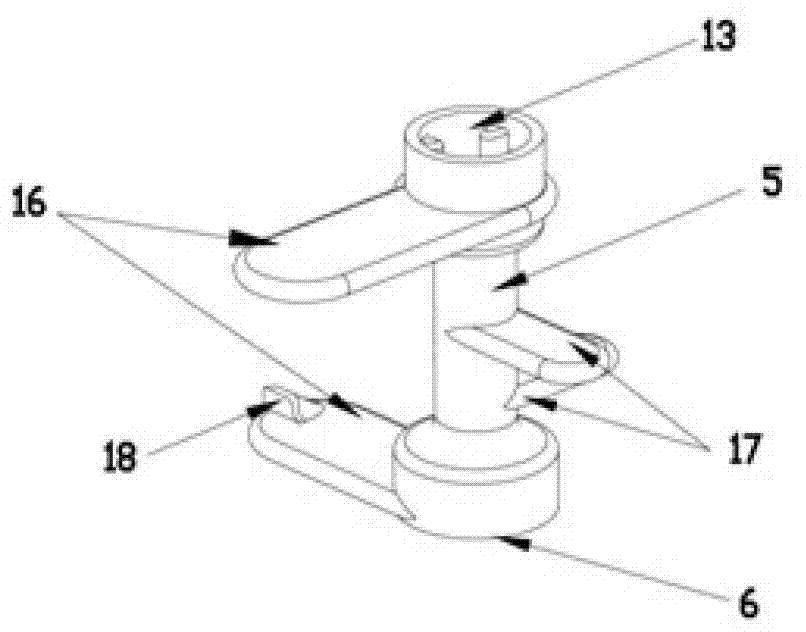

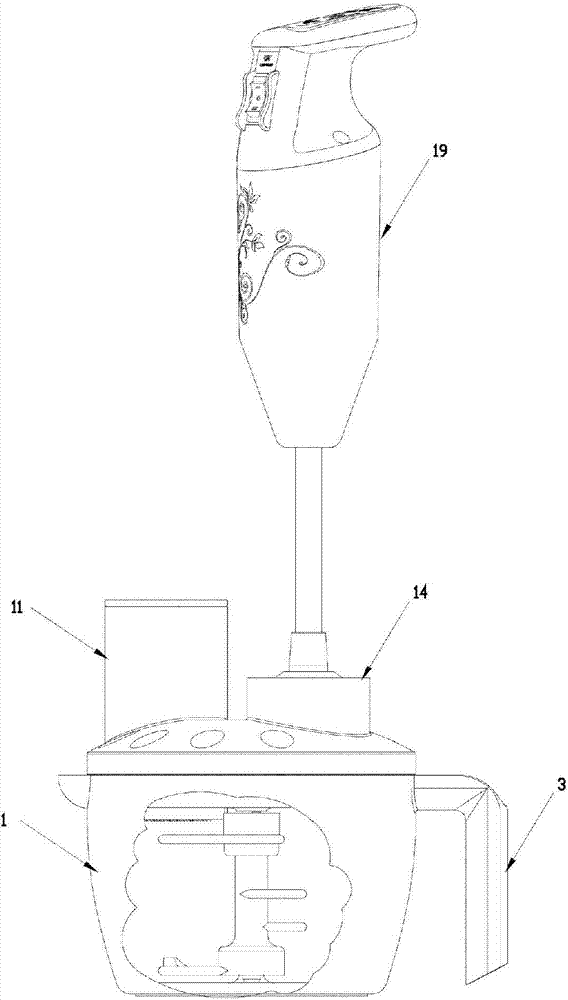

[0012] The main structure of this embodiment includes a barrel body 1, a vertical shaft 2, a handle 3, a card slot 4, a dough mixer 5, an inner idling shaft 6, a convex card 7, a connector 8, a transmission cover 9, a rotating shaft 10, and a feed port 11. Press-in rod 12, transmission shaft seat 13, power seat 14, deceleration device 15, long arm 16, short arm 17 and baffle plate 18; the main structure is divided into three parts: barrel body 1, dough mixer 5 and transmission cover 9 , a vertical shaft 2 is fixed at the center of the inner bottom of the barrel body 1, and a cylindrical kneader 5 is encased on the vertical shaft 2. The kneader 5 can be alternately replaced with other processing parts to realize different processing functions. The kneader 5 A transmission shaft seat 13 is formed at the center of the top end for the docking of the connector 8 to transmit power; The upper end is provided with a groove structure, and the connection between the rotating shaft 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com