Novel ultra-thin acoustic wave impedance transformer

A technology of acoustic impedance and impedance transformation, applied in the field of acoustics, can solve the problems of insufficient low-frequency characteristics and limited development space, and achieve the effect of improving the low-frequency effect, reducing the thickness and reducing the length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] This embodiment only includes one impedance transformation unit 1, such as Figure 4 shown.

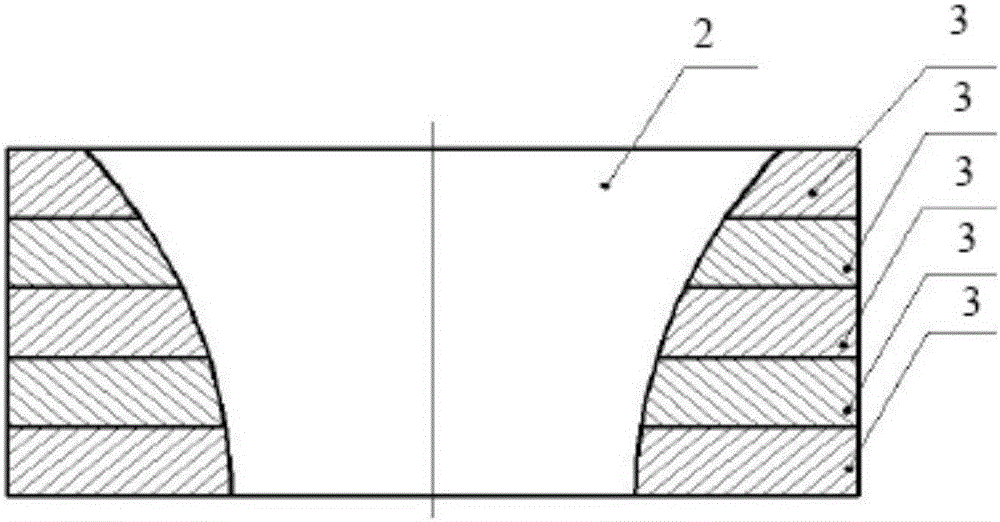

[0059] The framework adopts a multi-layer structure, such as image 3 As shown, the layers are fixed together by screws.

[0060] The cavity 2 in the frame is transparent up and down and is trumpet-shaped.

[0061] Wherein the prestressed film 4 and the acoustic material 5 are alternately placed inside the cavity 2 until the cavity 2 is filled.

[0062] Each layer of prestressed film 4 in the cavity 2 adopts the same type and material, and each layer of acoustic material 5 adopts the same structure type and material.

[0063] Wherein each layer of prestressed film 4 is a complete circular film, Figure 9 It is a partial enlarged view of the prestressed film 4 .

[0064] Wherein each layer of acoustic material 5 is a round table with variable cross-section, the side wall of the round table matches the inner wall of the trumpet-shaped cavity 2, Figure 16 It is a partially ...

Embodiment 2

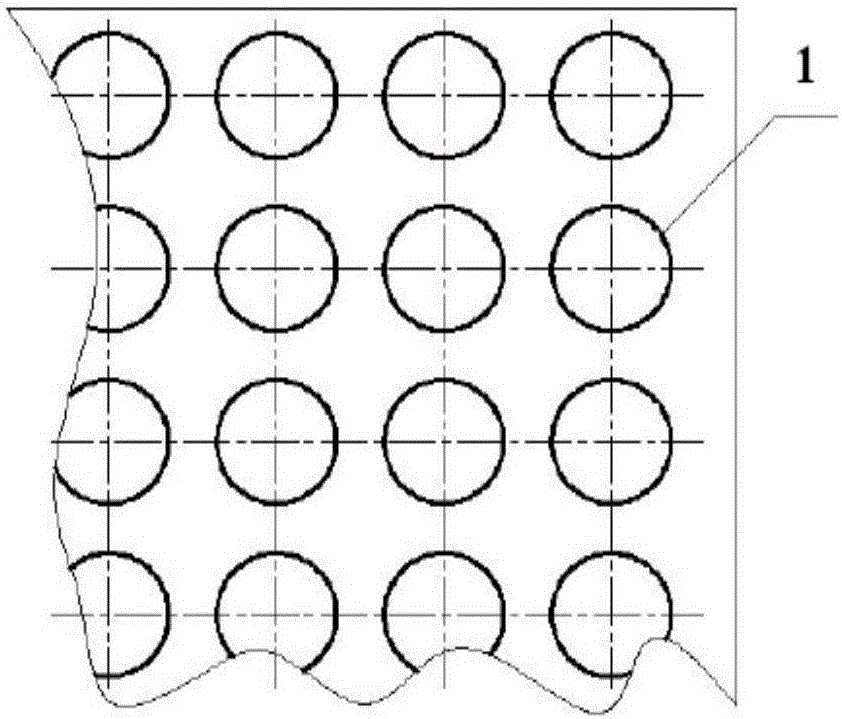

[0069] This embodiment is substantially the same as Embodiment 1, the only difference is that the prestressed film 4 adopts the hole type, Figure 10 It is a partial enlarged view of the prestressed film 4 .

Embodiment 3

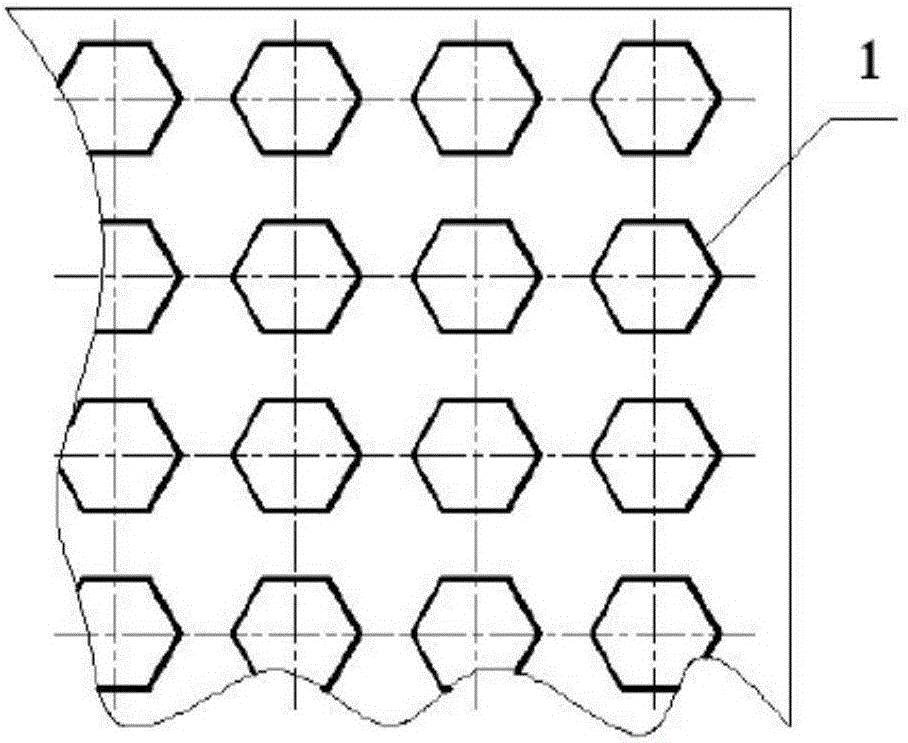

[0071] This embodiment is substantially the same as Embodiment 1, the only difference is that the prestressed film 4 adopts the hole type, Figure 11 It is a partial enlarged view of the prestressed film 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com