Composite polishing machine tool and polishing method

A compound machine tool and polishing fluid technology, applied in optical surface grinders, abrasive jet machine tools, grinding/polishing equipment, etc., can solve the problems of easily scratched and polluted workpieces, frequent loading, unloading and debugging, and achieve the effect of optimized integration and solution matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

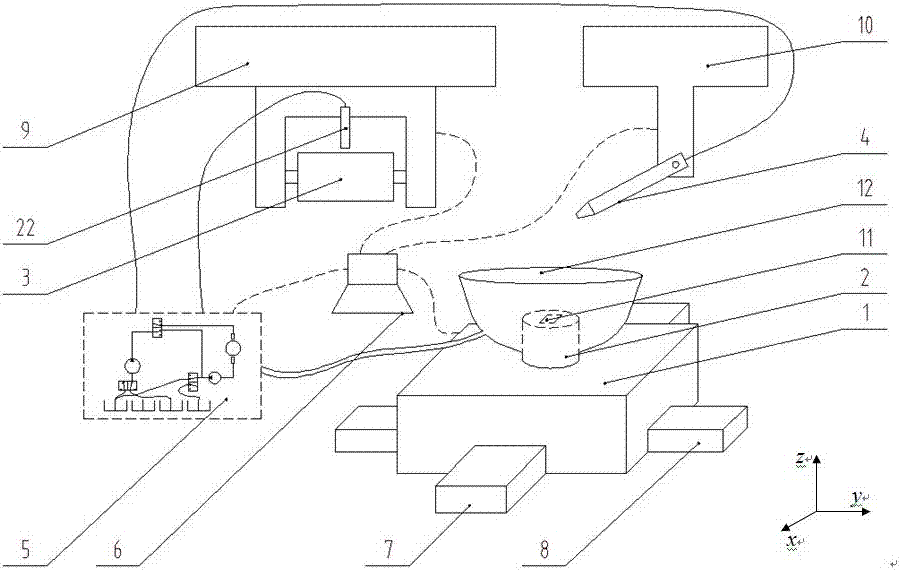

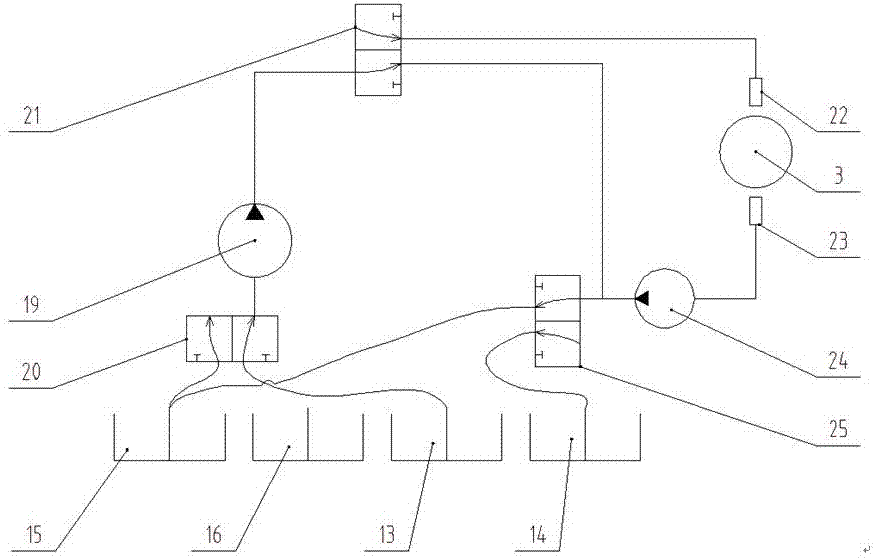

[0046] Such as figure 1 As shown, the compound polishing machine tool of the present invention includes a motion platform 1 , a circulation system 5 , a magnetorheological polishing device, a jet polishing device and a controller 6 . The optical element 11 is installed on the moving platform 1, driven by the moving platform 1, the optical element 11 moves on the horizontal plane, and the magnetorheological polishing device or jet polishing device polishes the surface of the optical element 11 under the control of the controller 6, The circulatory system 5 supplies the polishing solution A for the magnetorheological polishing device and the polishing solution B or water for the jet polishing device; the controller 6 controls the movement of the motion platform 1 and the working order of the magnetorheological circulatory system and the jet circulatory system.

[0047] The magnetorheological polishing device and the jet polishing device are fixed on the Z1 axis 9 and the Z2 axis...

Embodiment 2

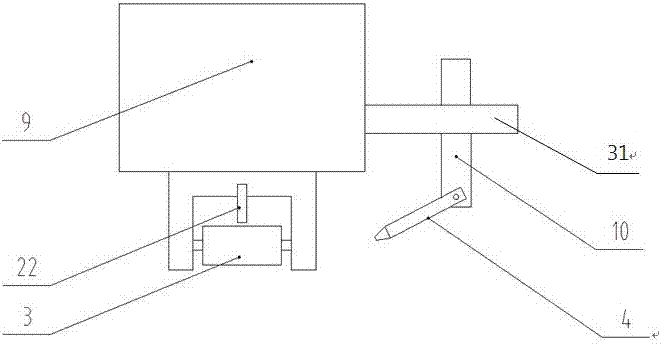

[0079] Embodiment 2 is basically the same as embodiment 1, the main difference is that figure 2. The jet polishing device is fixed on the support beam 31 on the magnetorheological polishing device, the magnetorheological polishing device and the jet polishing device are respectively fixed on the Z1 axis 9 and the Z2 axis 10, and the magnetorheological polishing device drives the jet polishing device along the Z1 axis direction movement, the jet polishing device independently moves along the Z2 axis direction and the horizontal direction of the support beam 31, and the magnetorheological polishing device and the jet polishing device move to the polishing position under the control of the controller 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com