How to use the quick release device

A purpose, technology of locking parts, applied in the field of high-acceleration drop impact test, can solve the problems of inconvenient hoisting of large-volume test pieces, high cost, limited lifting height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

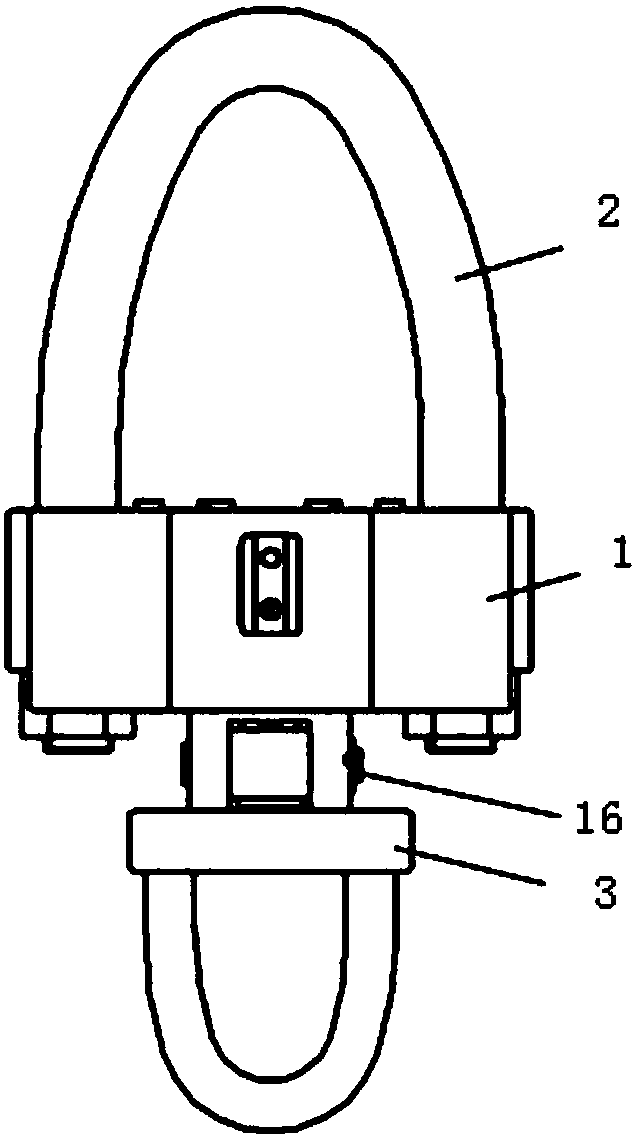

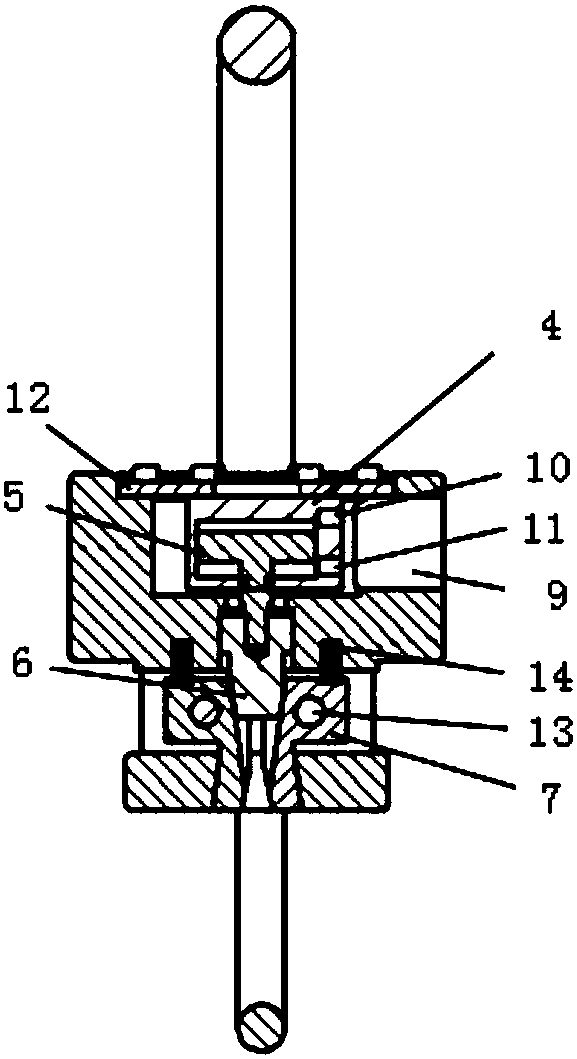

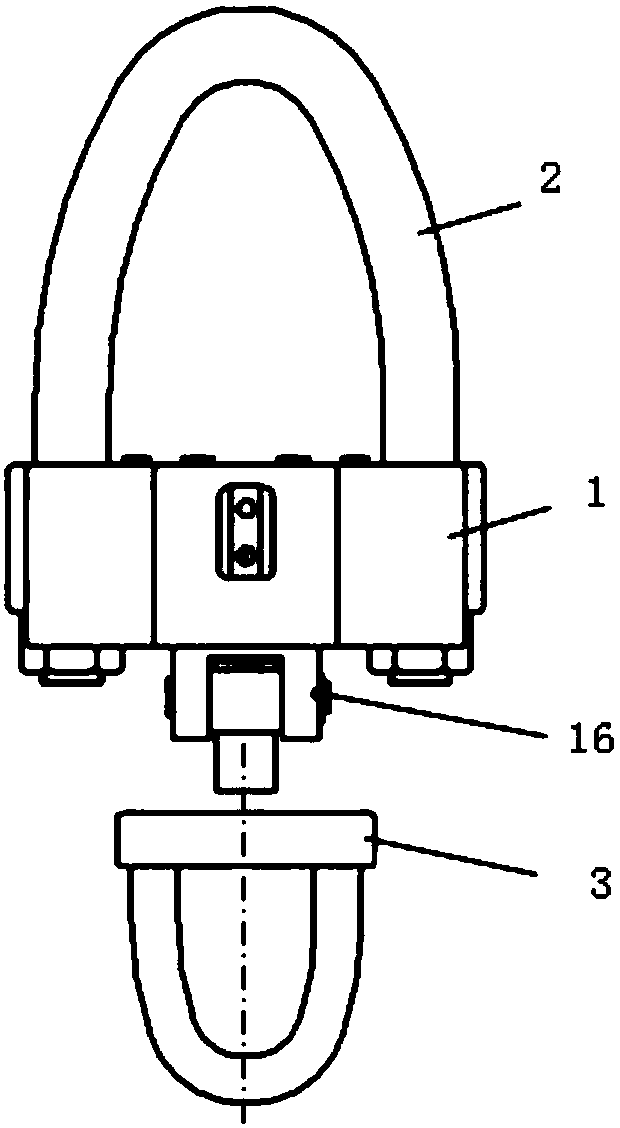

[0027] figure 1 The front view before the release of the pneumatic quick-release device provided by the embodiment of the present invention; figure 2 for figure 1 Front sectional view of the pneumatic quick-release device shown; image 3 The front view after the release of the pneumatic quick release device provided by the embodiment of the present invention; Figure 4 for image 3 The front sectional view of the pneumatic quick-release device shown; Figure 1-4 As shown, the pneumatic quick-release device provided in this embodiment includes: a main body 1, a connecting portion 16 is provided at one end of the main body 1, a driving mechanism moving in the vertical direction is provided in the main body 1, and a lock is provided in the connecting portion 16. Tightening part 7, the driving mechanism moves downward or upward in the tapered hole 15 at one end of the locking part 7 to drive the diameter of the other end of the locking part 7 to become larger or smaller, and ...

Embodiment approach

[0045] As the first embodiment of the present invention, when the present invention adopts the air pressure-driven connection between the cylinder 4 and the cylinder piston 5, the cylinder 4 adopts a double-acting cylinder, and the upper gas passage 10 and the lower gas passage 11 of the cylinder 4 pass through the air pipe through hole 9 Connect with the air supply pipe respectively.

[0046] Before use, first connect the upper lifting lug 2 to the crane, and connect the lower lifting lug 3 to the test piece to be lifted or released, start the crane, and then perform the movement according to the following steps:

[0047] (i) The upper gas channel 10 of the cylinder 4 exhausts, the lower gas channel 11 intakes air, the cylinder piston 5 drives the thimble 6 to move upward to the dead point, and under the action of the return spring 14, the lower end of the locking member 7 shrinks to close For the purpose, the inverted taper hole 8 of the lower lifting lug 3 can be pushed int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com