The hoisting method of large section steel truss girder

A hoisting method and technology of steel truss girder, applied in the directions of transportation and packaging, load hoisting components, etc., can solve the problems of poor economy, high economic cost, long time consumption, etc., and achieve increased effective hoisting weight, strong operability, Economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

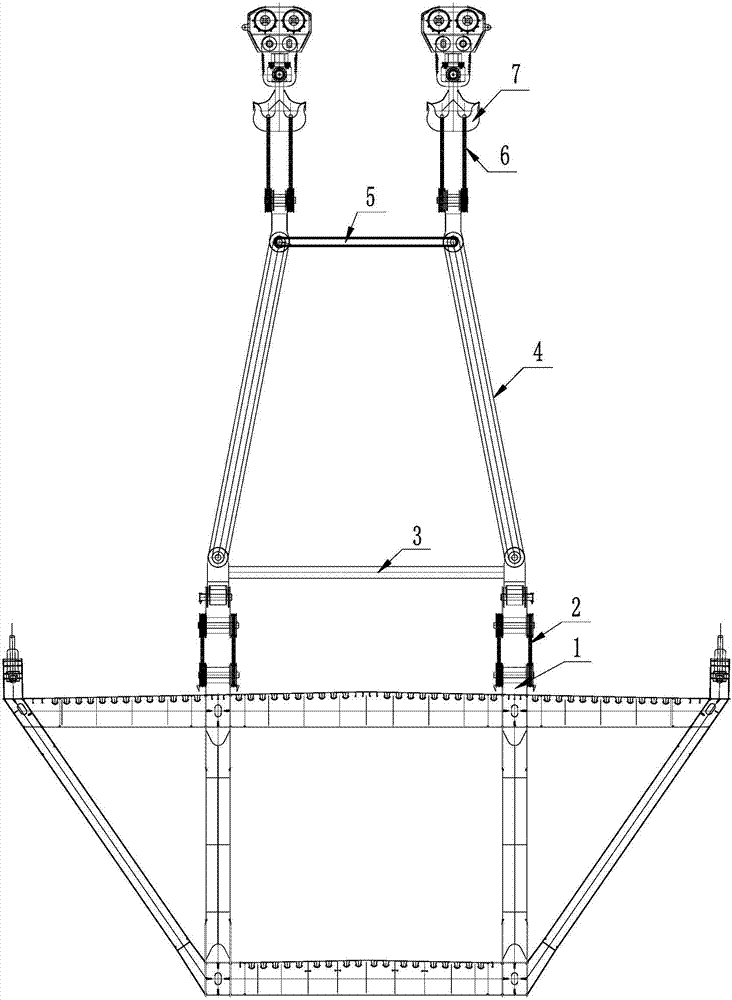

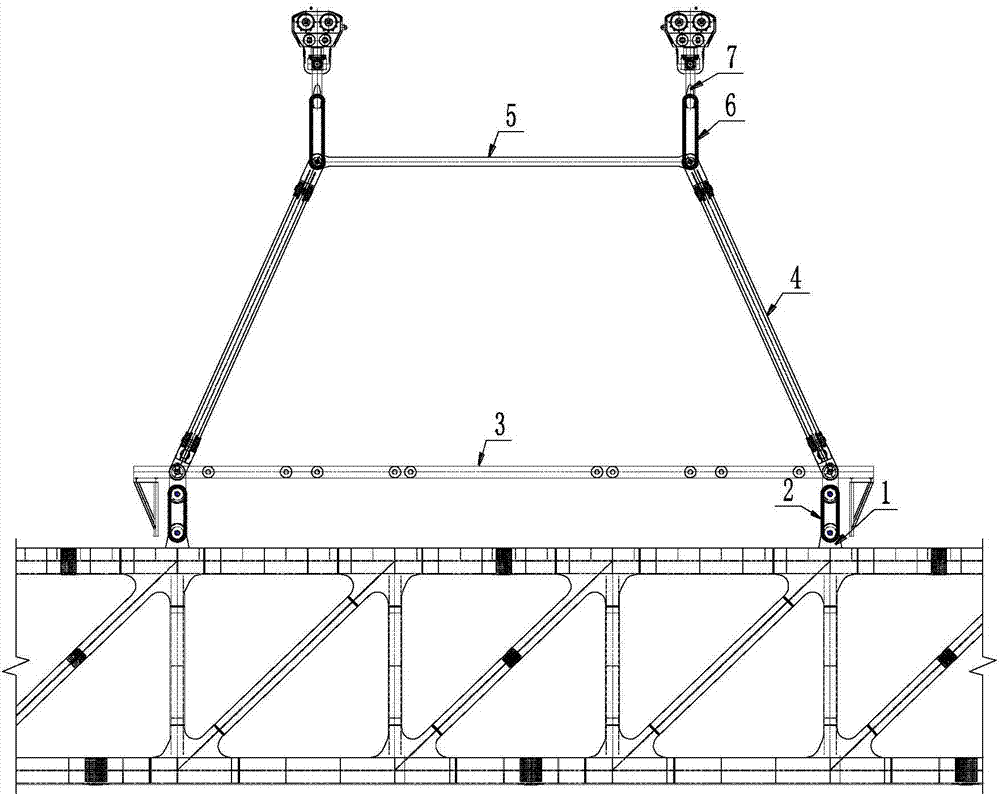

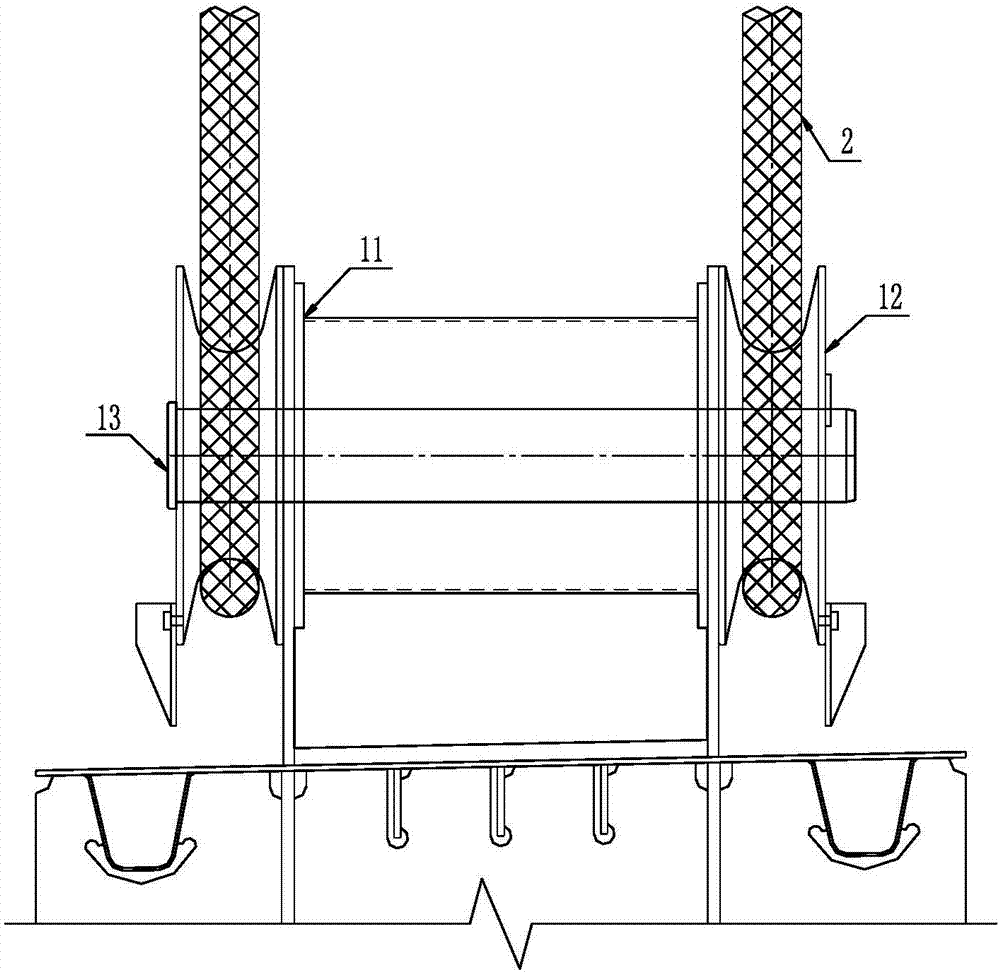

[0041] See figure 1 , figure 2 As shown, the embodiment of the present invention provides a hoisting tool for hoisting a large-segment steel truss beam. The hoisting tool is symmetrical along the longitudinal centerline as a whole, and includes a first rope loop 2 and a first connecting component arranged in order from bottom to top 3. The flexible connecting piece 4, the second connecting component 5, and the second rope loop 6; the first connecting component 3 is connected to the lifting lug 1 of the steel truss through the first rope loop 2, and the first connecting component 3 is connected to the flexible connecting piece 4 It is connected to the second connecting component 5, and the second connecting component 5 is connected to the hook 7 of the floating crane through the second rope loop 6.

[0042] The steel truss beam hoisted by the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com