A refinery catalyst sulfur-containing wastewater denitrification process and its application

A refinery catalyst and wastewater technology, applied in the field of water treatment, can solve problems such as high alkalinity, high sulfate content, and far-reaching control of total nitrogen emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] This embodiment provides a process for denitrification of sulfur-containing wastewater by an oil refining catalyst.

[0064] The refinery catalyst sulfur-containing waste water that present embodiment adopts is former waste water, wherein the content of sulfate is 3600mg / L, the nitrogen content of nitrogen ammonia is 120mg / L, and the nitrogen content of nitrate nitrogen (comprising nitrate and nitrite) is 25mg / L, the content of heavy metal Cd is 12mg / L, the original wastewater also contains other heavy metals;

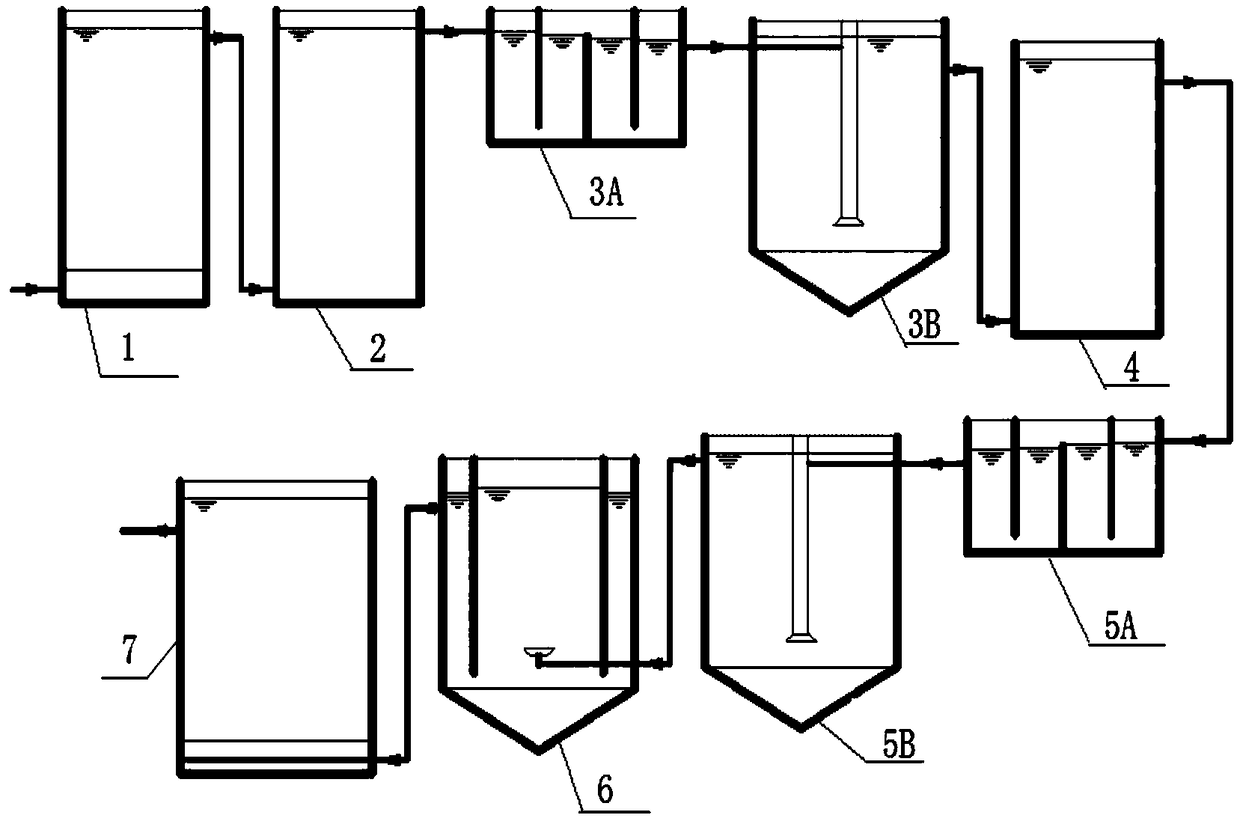

[0065] Establish a treatment system for denitrification process of refinery catalyst sulfur-containing wastewater, such as figure 1 Shown:

[0066] Anaerobic hydrolysis process section: import the petroleum refining catalyst wastewater into the hydrolysis tank (1) for anaerobic hydrolysis treatment to degrade the refractory macromolecular organic matter, that is, hydrocolloid substances, to form the first wastewater effluent, and control the The pH value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com