Combined stirrer used for mechanical stirring desulfurization of molten iron and manufacturing method of combined stirrer

A technology of mechanical stirring and agitator, which is applied in the field of combined agitator and its preparation and desulfurization by mechanical stirring of molten iron, can solve the consumption cost of agitator, environmental pollution and safety hazards, and the high cost of agitator preparation, which aggravates the desulfurization of molten iron. and other problems, so as to ensure the quality of preparation and performance, reduce the cost of preparation and use, and ensure the function of use and mixing and mixing characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

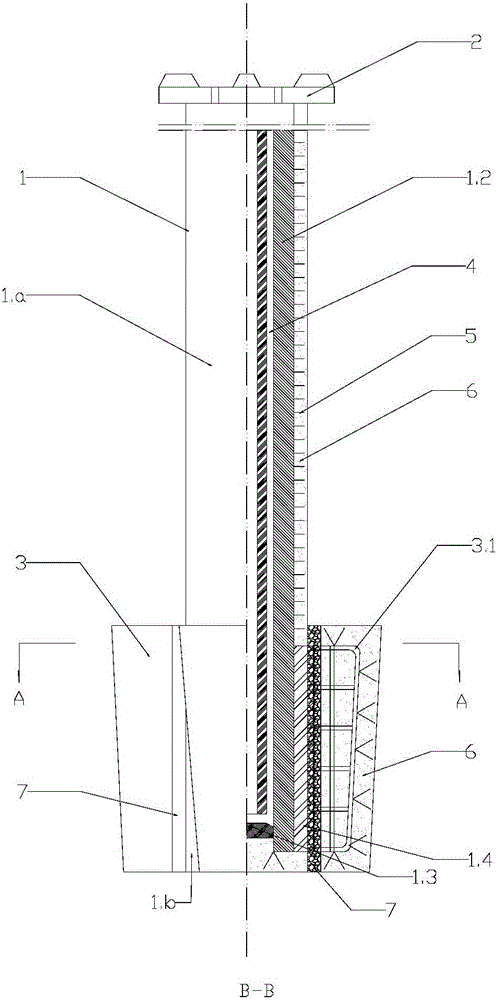

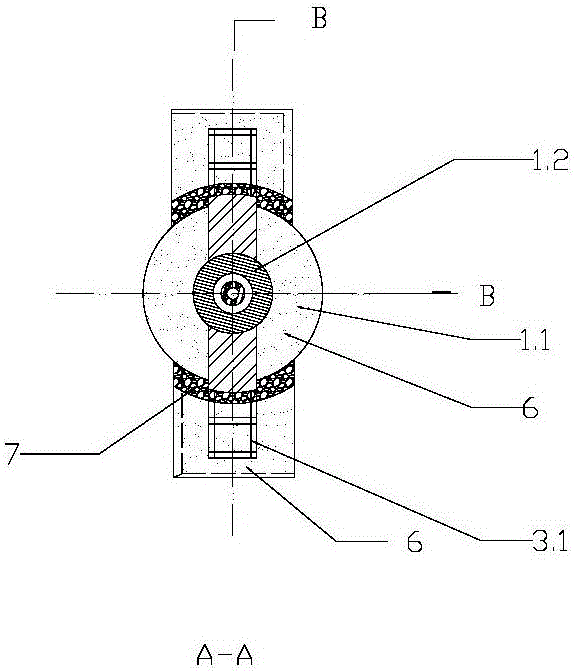

[0049] Such as Figure 1~2 Shown: a combined agitator for mechanical stirring and desulfurization of molten iron, which includes a stirring shaft and a connecting flange 2 arranged above the stirring shaft 1, the stirring shaft 1 is composed of shaft section 1.a and blade section from top to bottom 1.b consists of two composite stirring blades 3 symmetrically arranged on the outer wall of the blade segment 1.b, each composite stirring blade includes a metal skeleton 3.1, the stirring shaft 1 includes an air-cooled tube 1.1 and a stirring shaft metal core 1.2, the stirring shaft The bottom of the inner wall of the metal core 1.2 is provided with a metal plug 1.3, the air-cooled tube 1.1 is inserted into the metal core 1.2 of the stirring shaft, the air-cooled tube 1.1, the metal plug 1.3 and the metal core 1.2 of the stirring shaft form a cooling cavity 4, and the blade segment 1. The outer wall of the stirring shaft metal core 1.2 is uniformly distributed and welded with multi...

Embodiment 2

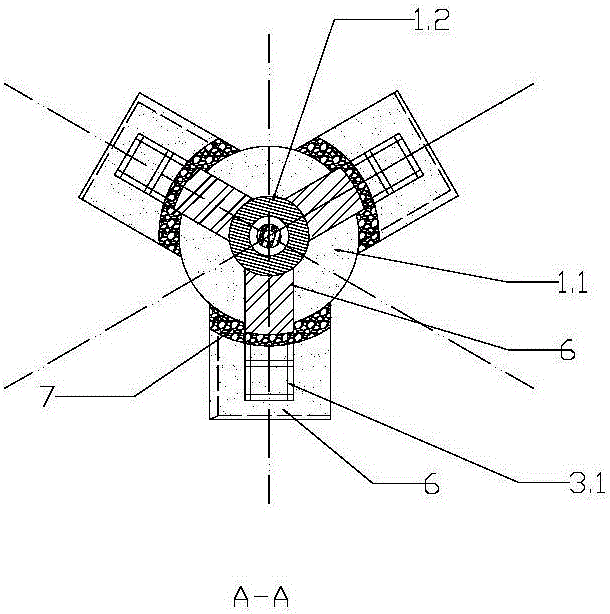

[0083] Such as figure 1 and 3 As shown, the stirrer structure of the present embodiment is basically the same as that of embodiment 1, the difference is:

[0084] The number of composite stirring blades 3 is three.

Embodiment 3

[0086] Such as figure 1 and 4 As shown, the stirrer structure of the present embodiment is basically the same as that of embodiment 1, the difference is:

[0087] The number of composite stirring blades 3 is three.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com