A central flushing device for a centrally closed cutter head

A closed, cutter head technology, applied in mining equipment, earth square drilling, tunnels, etc., can solve the problems of easy mud cake formation, achieve the effects of preventing muck cake formation, improving work efficiency, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

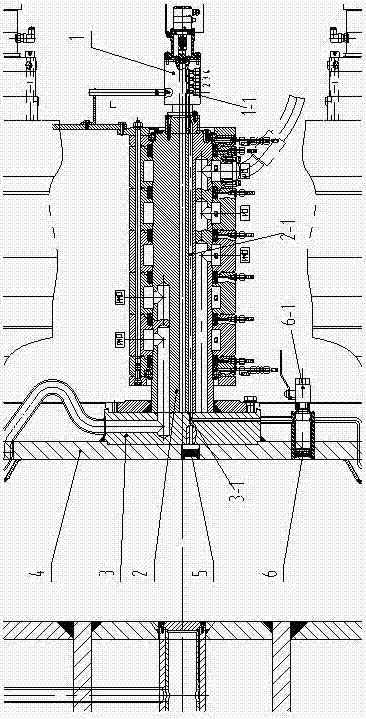

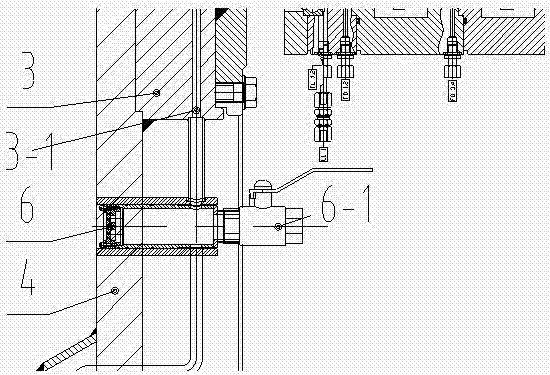

[0013] Such as Figure 1-2 As shown, a center-closed cutter head center flushing device includes a small rotary joint 1, a large rotary joint 2, a transition piece 3, a cutter head flange 4 and a spout. The small rotary joint 1 is installed on the large rotary joint 2 and It is connected in series with the large rotary joint 2, the large rotary joint 2 is fixed on the transition piece 3, the transition piece 3 is fixed on the cutter head flange 4, the nozzle is installed on the cutter head flange 4, the channel I1-1 of the small rotary joint 1 It is docked with the channel II2-1 of the large rotary joint 2, the channel II2-1 is connected with the channel III3-1 on the transition piece 3, and the channel III3-1 is connected with the nozzle.

[0014] In this embodiment, the spout includes spout I5 and spout II6, spout I5 and spout II6 are installed on the cutter head flange 4, and the channel III3-1 is divided into two paths, one path is connected with spout I5, and the other pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com