Non-contact electric-arc-furnace continuous temperature measuring gun structure

A non-contact, electric arc furnace technology, applied in the direction of measuring devices, optical radiation measurement, radiation pyrometry, etc., can solve the problem of insufficient support of dynamic metallurgical model data, inability to realize continuous online temperature measurement, infrared temperature sensor coaxial, etc. Problems, to achieve the effect of long-distance temperature measurement, small attenuation of optical radiation, and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The preferred embodiments of the present invention will be described in detail below; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

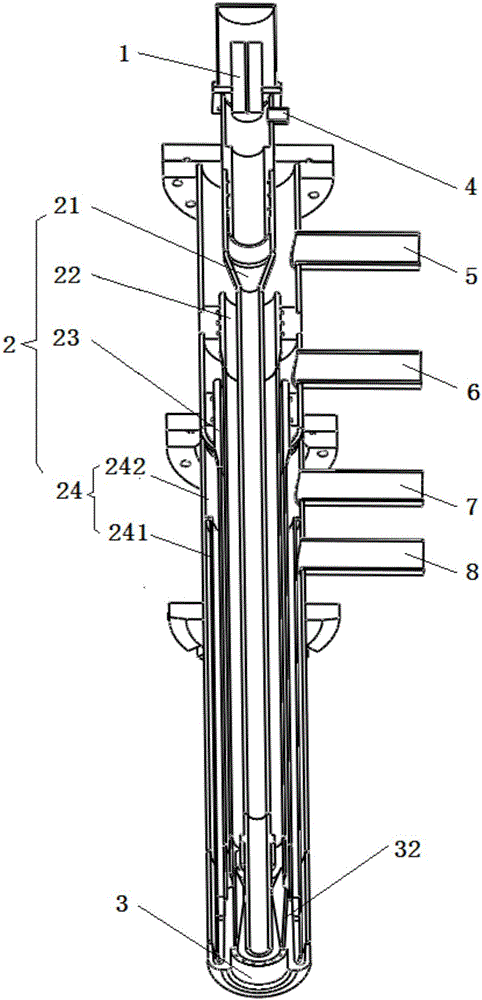

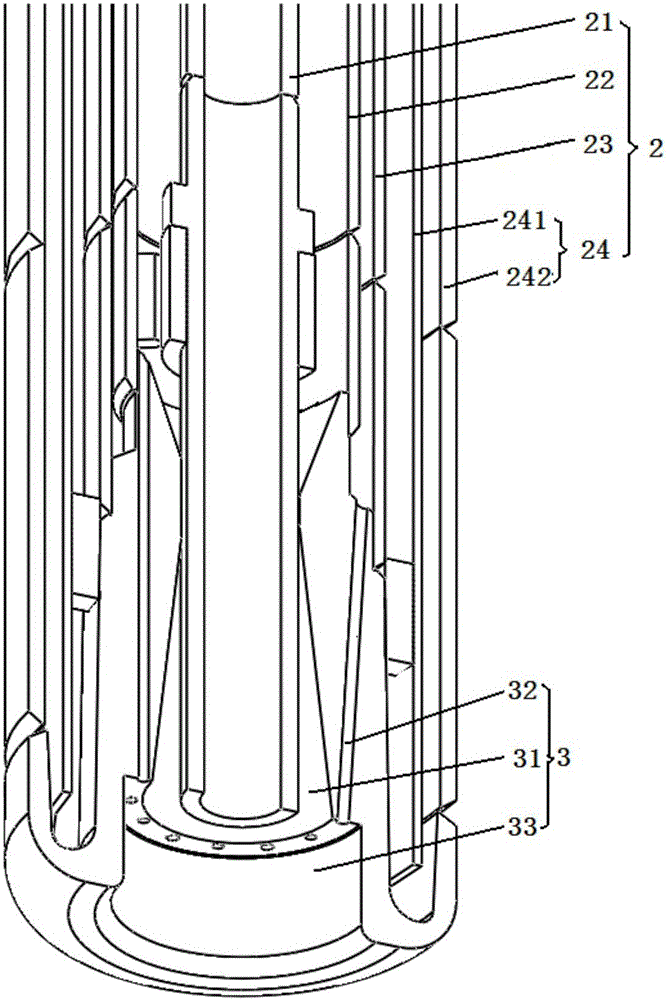

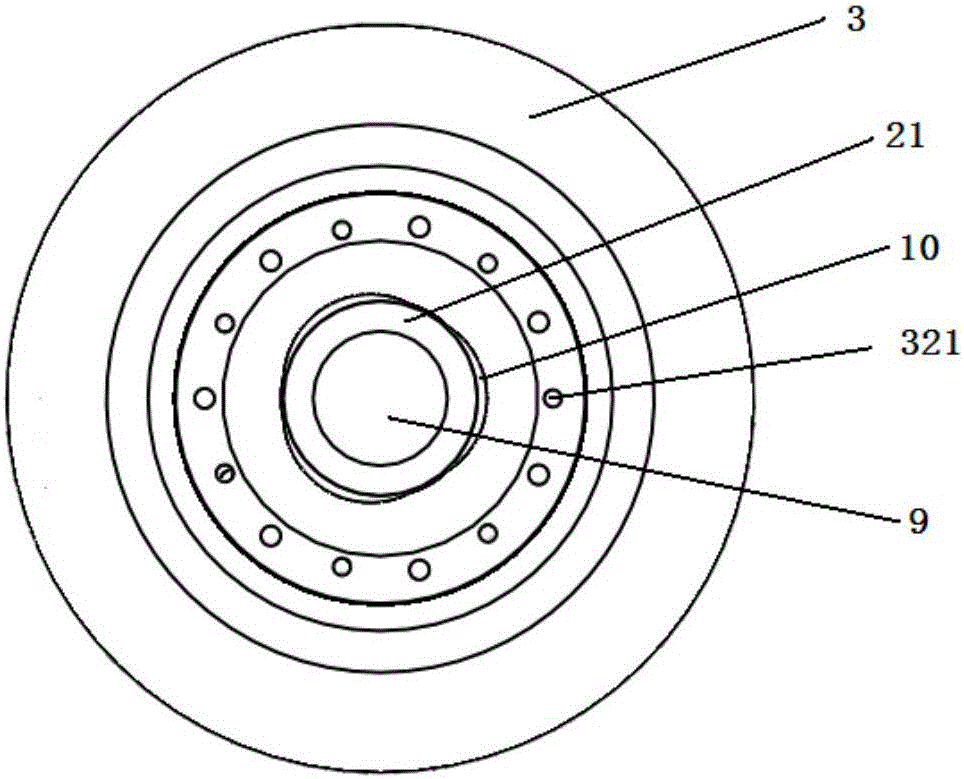

[0024] like Figure 1-3 As shown, a non-contact electric arc furnace continuous temperature measuring gun structure includes a ring-hole cluster spray gun and an infrared temperature measuring probe 1. The ring-hole cluster spray gun is provided with a cooling water jacket 24, a supersonic air flow nozzle, and an accompanying flow and combustion chamber. Hole 32 and peep pipe 21; in the structure of the present invention, the gun bar 2 of this ring-hole cluster spray gun is mainly made up of coaxial peep pipe 21, main air pipe 22, accompanying air pipe 23, water-cooled inner pipe 241 and water-cooled outer pipe 242 , and correspondingly provided with protective gas inlet 4, main gas inlet 5, accompanying gas inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com