An electric arc furnace supersonic ring combustion cluster carbon oxygen lance and nozzle structure

A technology of ring-burning cluster carbon-oxygen lance and supersonic speed, which is applied in the direction of electric furnace, furnace, furnace components, etc., can solve the problems that restrict the development of electric arc furnace smelting process, the distance of powder injection is short, and the powder can not be wrapped, etc., to achieve increase The function of electric arc furnace equipment, the effect of improving efficiency and increasing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described in detail below; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

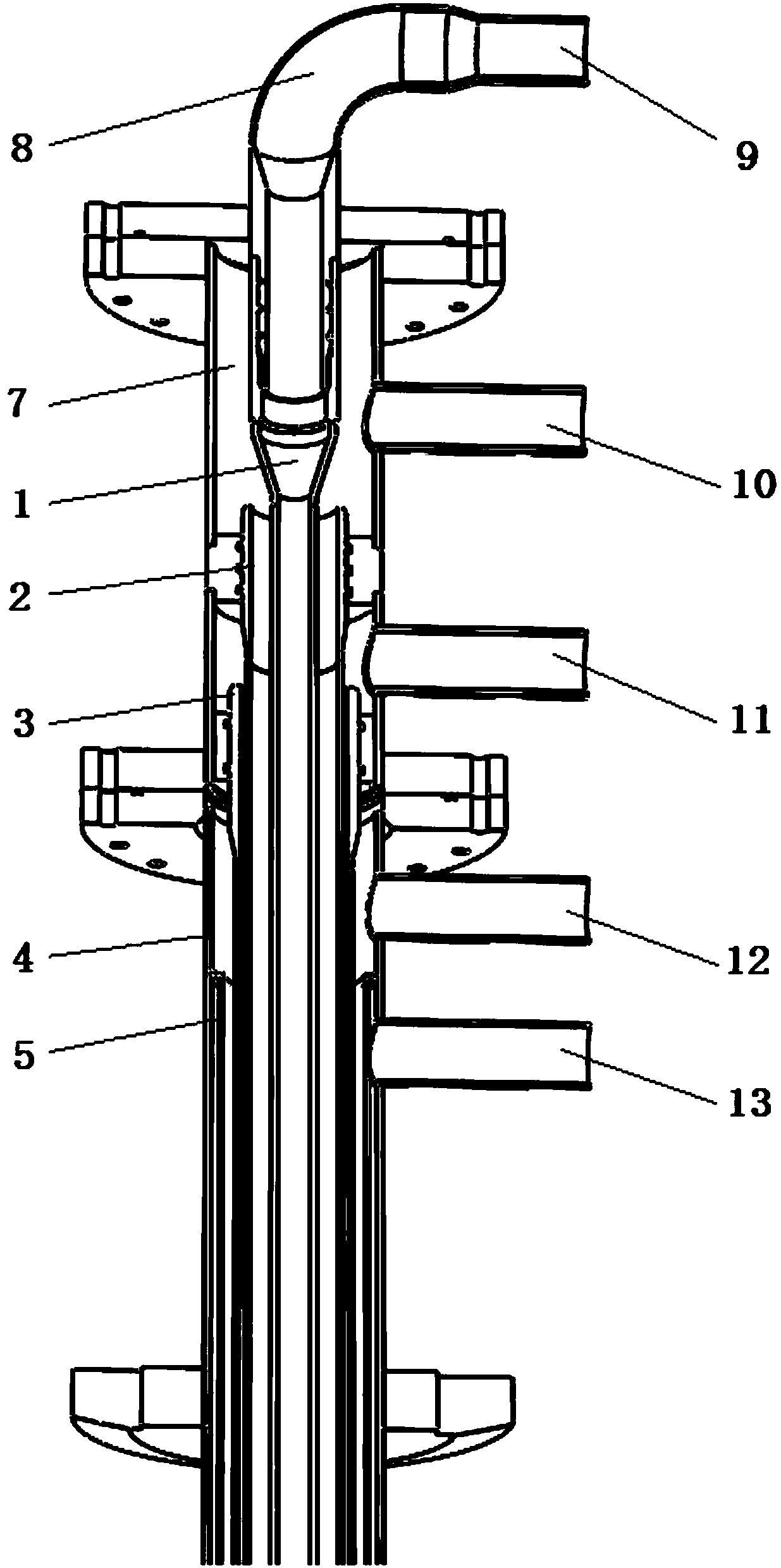

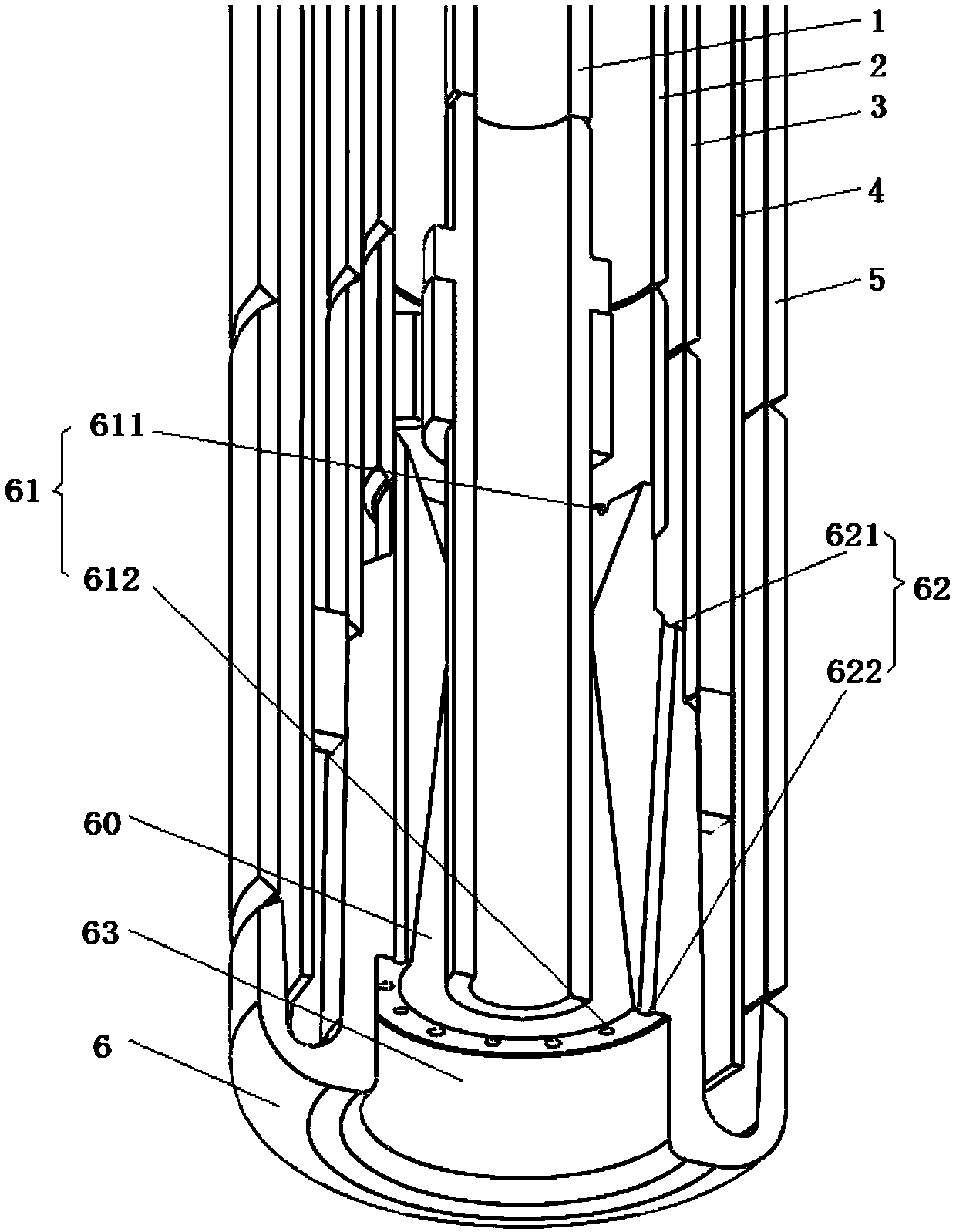

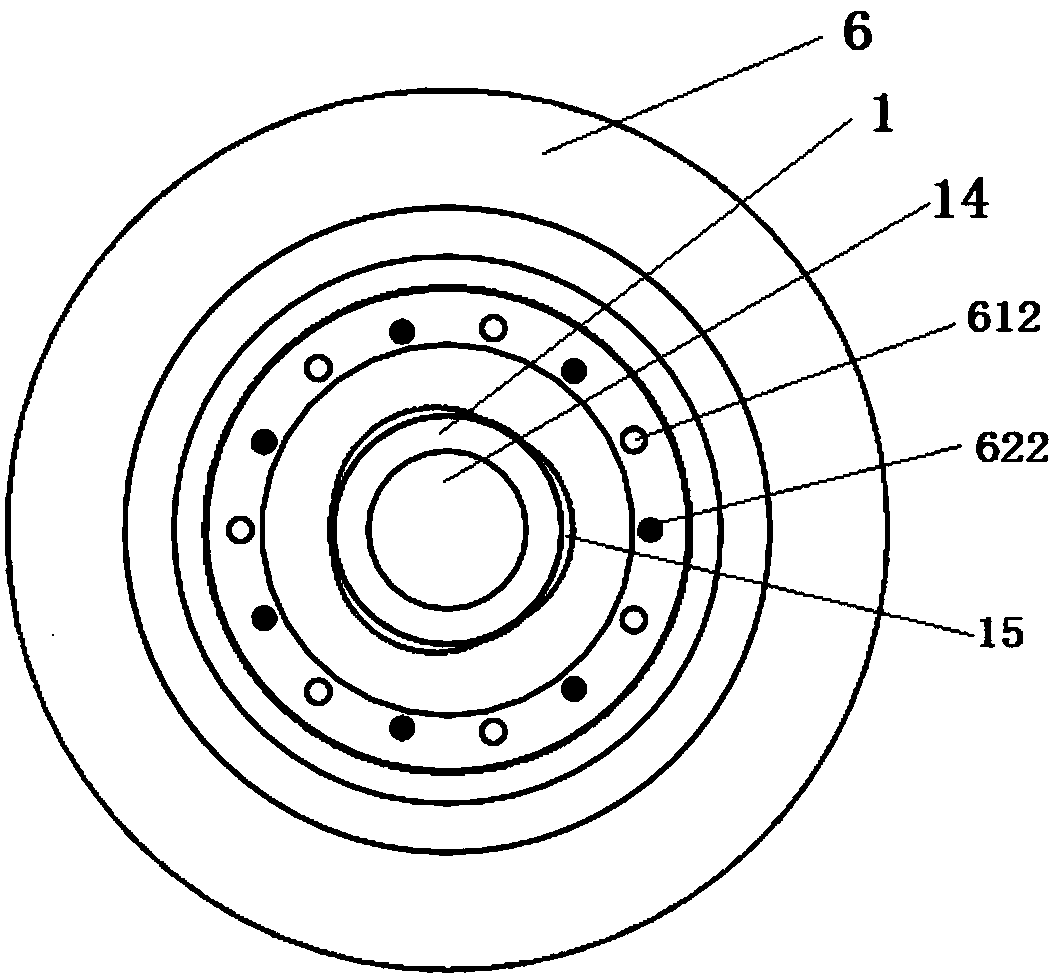

[0028] Such as Figure 1-3 As shown, an electric arc furnace supersonic ring combustion cluster carbon-oxygen gun and nozzle structure includes a gun shaft and a cluster nozzle 6, and the gun shaft includes a powder tube 1 coaxially arranged, an oxygen tube 2, a gas tube 3, and a water-cooled inner tube 4 And the water-cooled outer tube 5, and the sealing assembly 7 and the powder inlet assembly 8, and are respectively provided with a powder inlet 9, an oxygen inlet 10, a gas inlet 11, a cooling water inlet 12 and a cooling water outlet 13, and the cluster nozzle includes a central hole 60. Epoxy small hole 61, ring combustion small hole 62 and combustion orientation chamber 63, the oxygen pipe 2, the gas pipe 3, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com