Fixing device for sample-loading copper grid

A fixing device and copper mesh technology, applied in the preparation of test samples, etc., can solve the problems of affecting observation, easy to pinch Fanghua film, mechanical damage to slices, etc., to save dyeing liquid and realize the effect of automatic dyeing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The fixing device of the present invention will be further described in detail below with reference to the accompanying drawings.

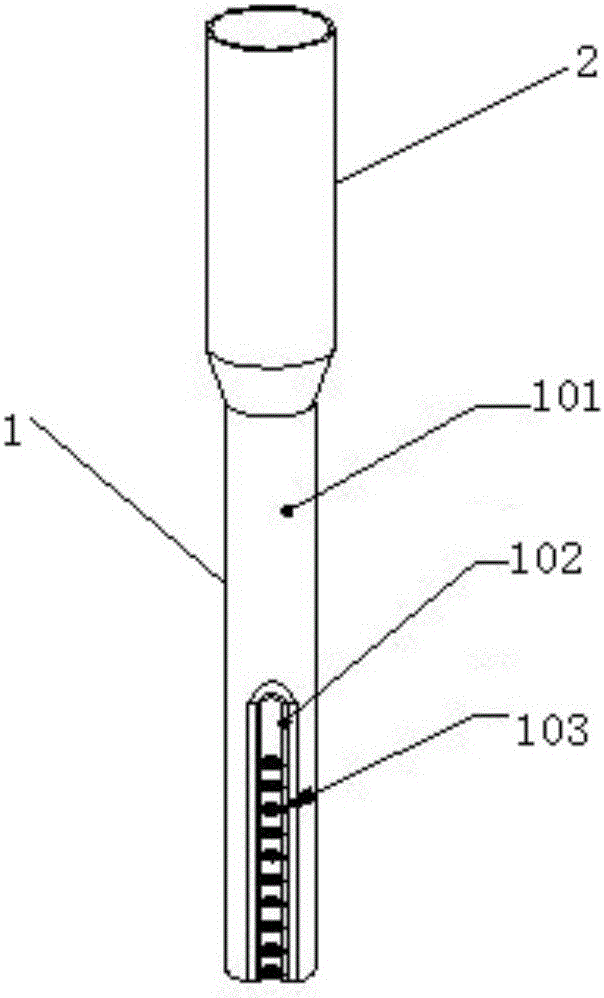

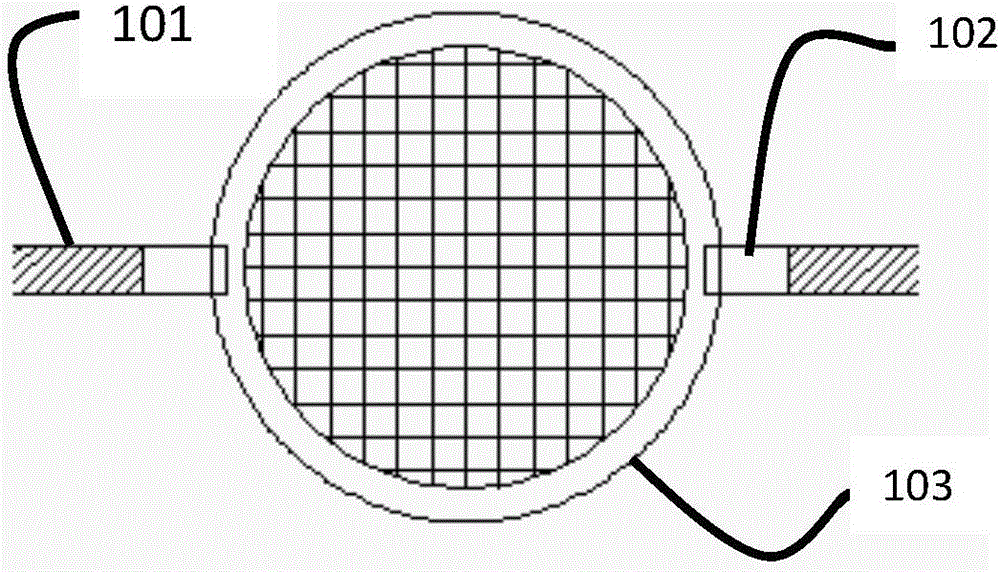

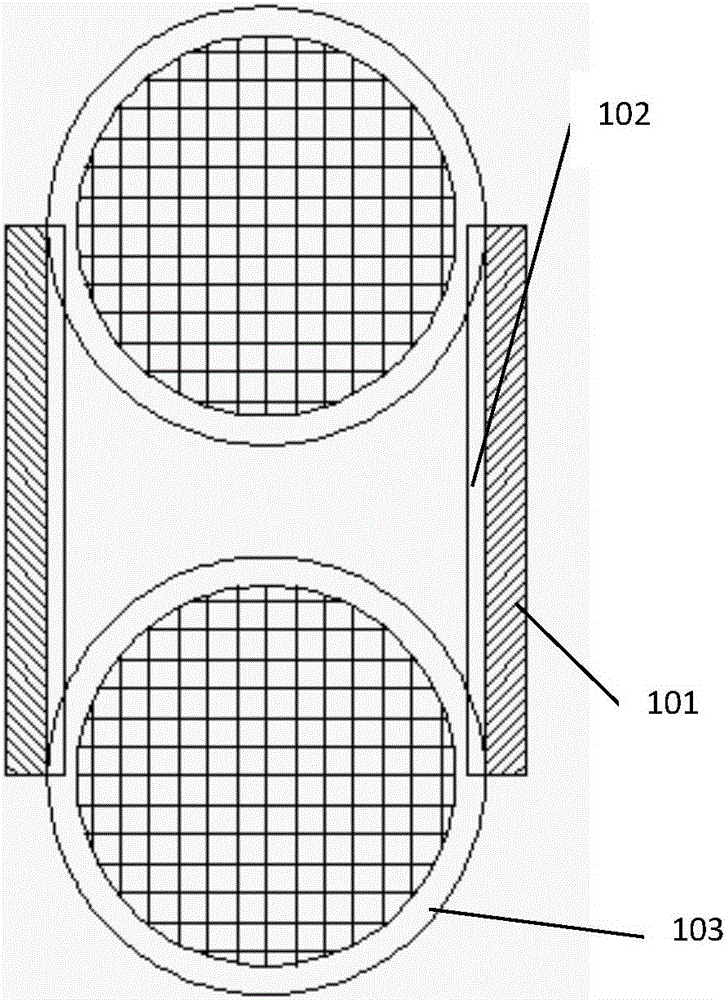

[0029] figure 1 It is a schematic diagram of an arc-shaped fixing device. The fixing device includes a main body 1 and an auxiliary body 2. The auxiliary body 2 plays a role in fixing and supporting the main body 1 of the net. The main body 1 of the net is made of a hard layer of plastic, glass, and stainless steel. 101. The soft layer 102 of wax is composed of a hard layer 101 of plastic, glass, and stainless steel covered with a layer of wax layer 102, and the wax layer 102 at the opening of the arc is symmetrical to the two ends of the copper mesh 103 For fixing, the distance between the wax layer 102 arc-shaped openings is 1.2mm to 2.8mm, the thickness of the wax layer is 0.4mm to 1.5mm, and the distance between the arc-shaped openings of the hard layers of the plastic layer, glass layer, and stainless steel layer The distance is 1.6mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com