New energy automobile motor stator copper wire fusion welding assisting device

A new energy vehicle, motor stator technology, applied in welding/cutting auxiliary equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of copper wire shaking, copper wire not fixed, affecting operation, etc., to achieve stable fixation and good adjustment , to avoid the effect of burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

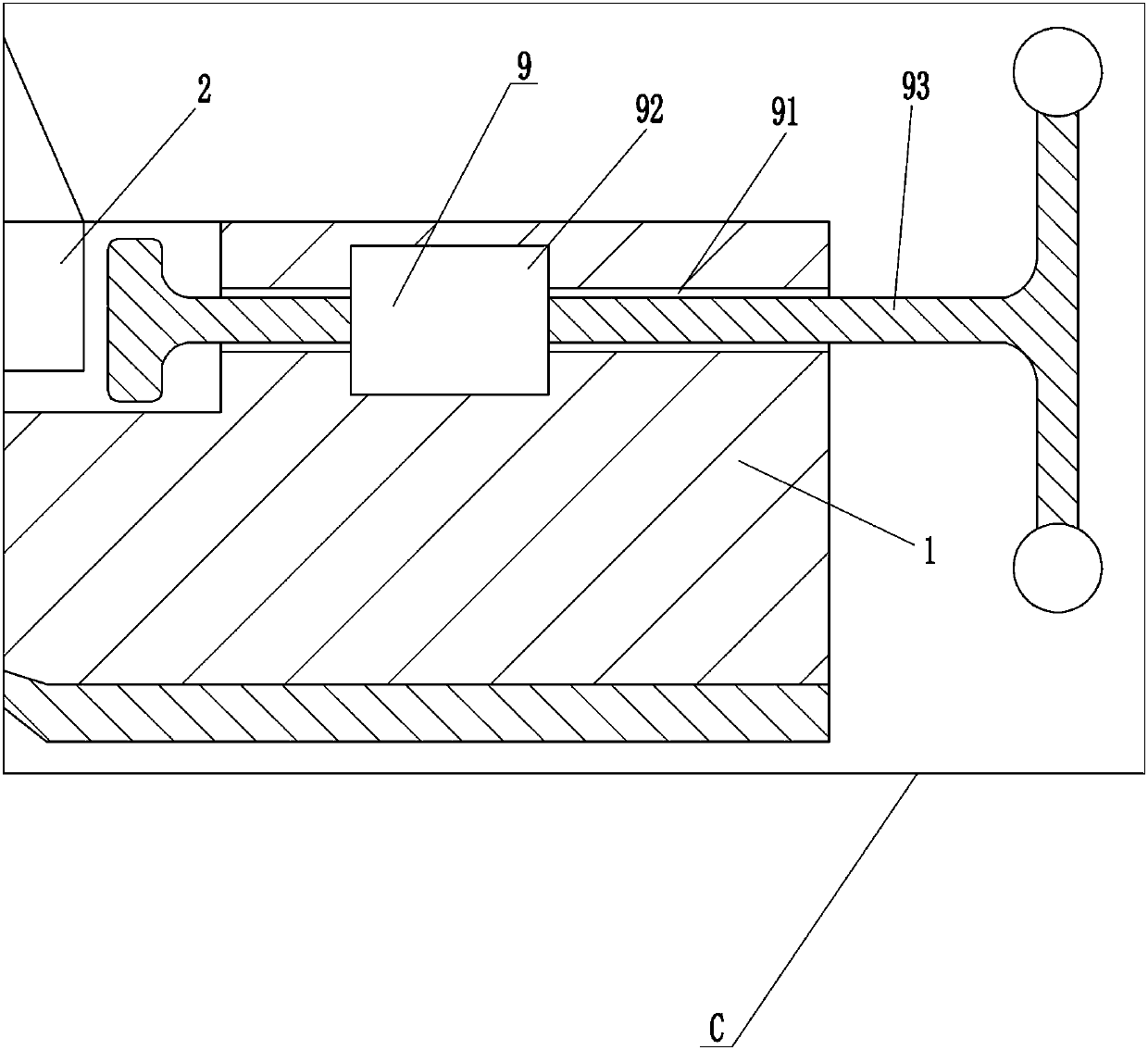

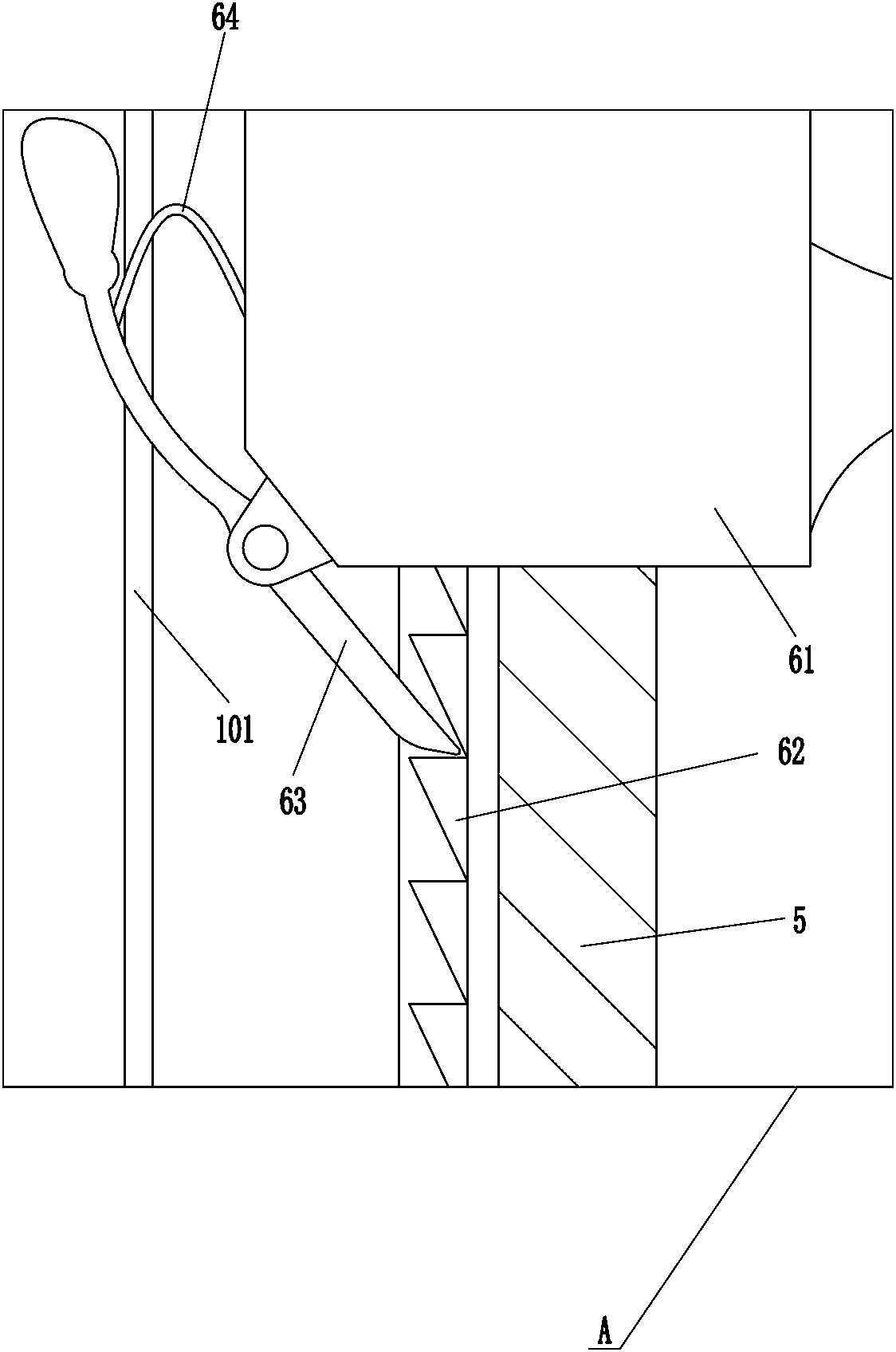

[0024] A new energy automobile motor stator copper wire fusion welding auxiliary device, such as figure 1 As shown, it includes a base 1, a turntable 2, a placement plate 3, a centering column 4, a vertical rod 5, a height adjustment mechanism 6, and a fixing mechanism 7. The top of the base 1 is rotatably installed with a turntable 2. 2 connection, the top of the turntable 2 is provided with a placing plate 3 and a centering column 4, the centering column 4 is located in the placing plate 3, the left side of the placing plate 3 is connected with a vertical rod 5, and the vertical rod 5 is provided with a height adjustment mechanism 6, the height The adjusting mechanism 6 is provided with a fixing mechanism 7, the fixing mechanism 7 is used for fixing the copper wire, and the height adjusting mechanism 6 is used for adjusting the height of the fixing mechanism 7.

[0025] When the copper wire needs to be welded, people put the motor stator on the centering column 4, and then c...

Embodiment 2

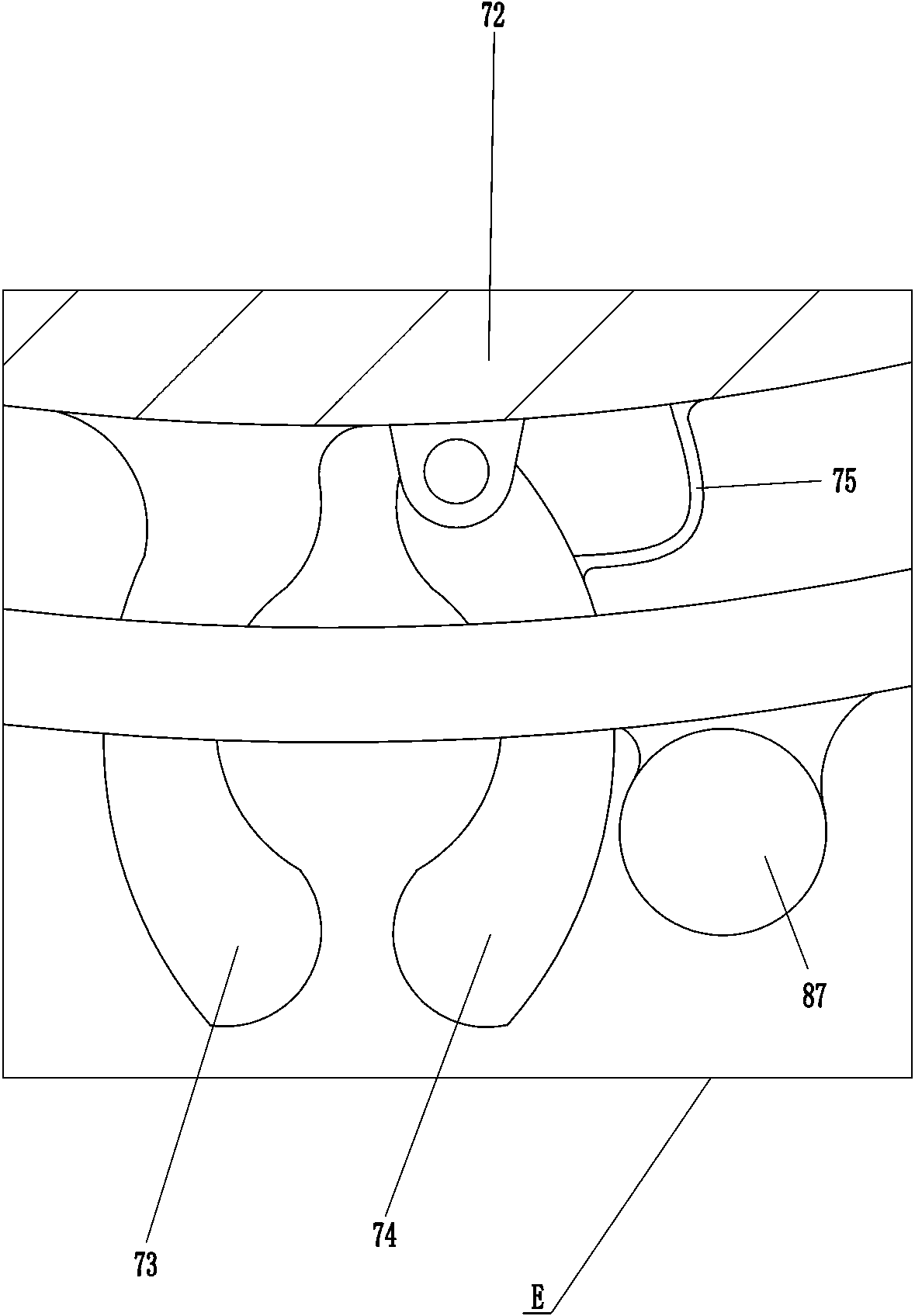

[0031] On the basis of Example 1, such as Figure 5 and Image 6 As shown, a reinforcement mechanism 8 is also included, and the reinforcement mechanism 8 includes a cross bar 81, a rotating rod 82, a mainspring 83, a tooth block 84, a second pawl 85, a third elastic member 86, a mounting ring 87 and a pressure head 88 , the fixed ring 72 is connected with a cross bar 81, the fixed ring 72 is connected with the cross bar 81 by means of bolt connection, the cross bar 81 is connected with a rotating rod 82 and a second pawl 85 in a rotating manner, and the second pawl 85 is located at the rotating On the right side of the bar 82, a spring 83 is provided at the junction of the turning bar 82 and the cross bar 81, and the right side of the turning bar 82 is connected with a tooth block 84, and the tooth block 84 cooperates with the second ratchet 85, and the second ratchet 85 and the cross bar 85 cooperate with each other. A third elastic member 86 is connected between the rods 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com