Modular combined high-voltage switch cabinet

A high-voltage switchgear and combined technology, applied in the field of modular combined high-voltage switchgear, can solve problems such as inconvenience and achieve the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

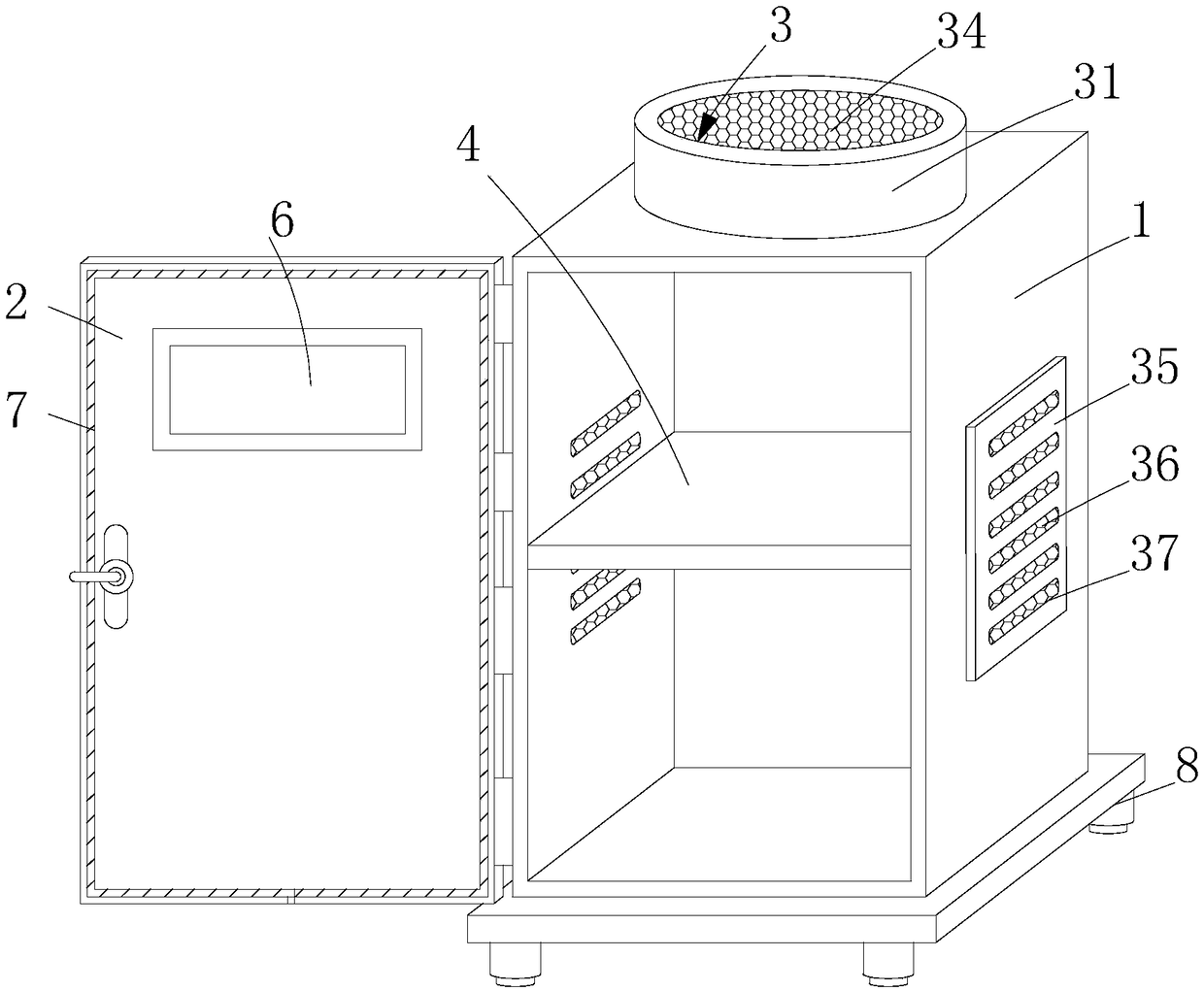

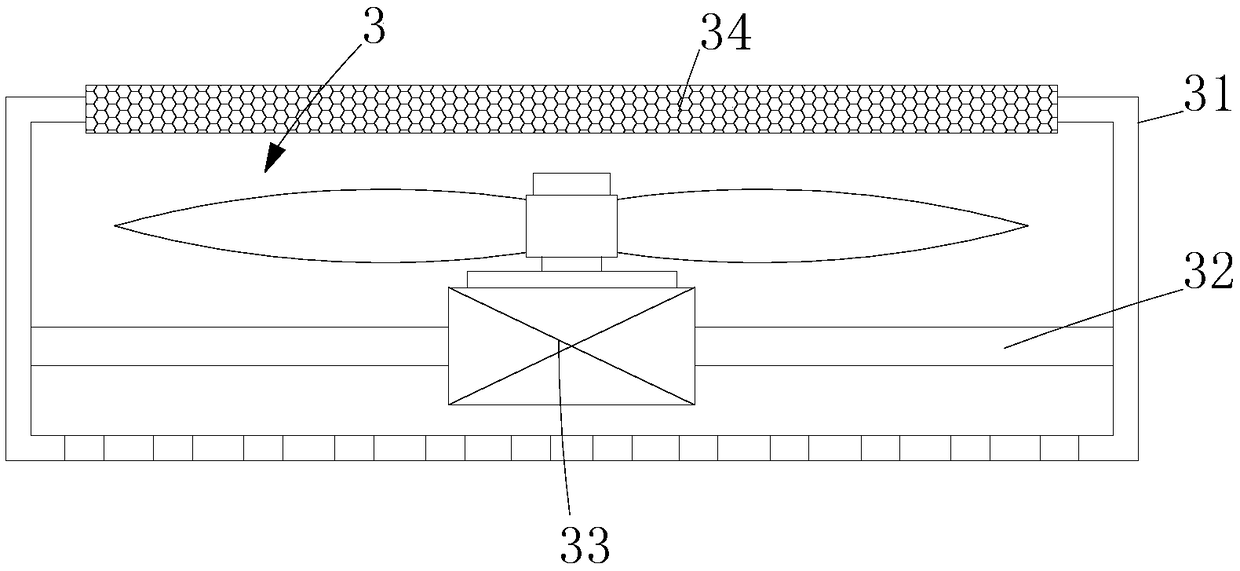

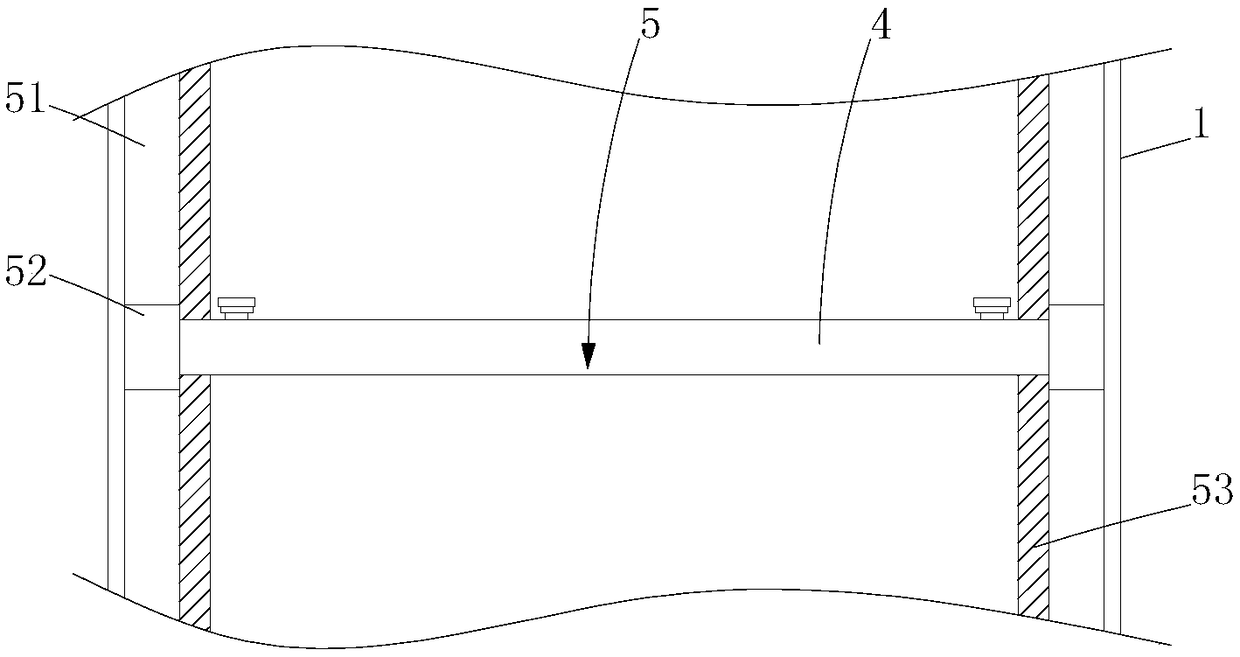

[0023] Such as Figure 1-4 As shown, the present invention provides a technical solution: a modular high-voltage switch cabinet, including a cabinet body 1, a cabinet door 2, a heat dissipation mechanism 3, a partition plate 4, an adjustment mechanism 5 and an observation window 6, and the cabinet door 2 The right side and the left side of the front of the cabinet body 1 are flexibly connected by hinges, the heat dissipation mechanism 3 is located on the cabinet body 1, the partition plate 4 is located inside the cabinet body 1, the adjustment mechanism 5 is located inside the partition plate 4, and the observation window 6 Located on the cabinet door 2, the shape of the observation window 6 is a rectangle, and the observation window 6 is a transparent plastic plate. The surroundings of the front of the cabinet door 2 and the back of the dust-proof strip 7 are bonded by glue, and the shape of the dust-proof strip 7 is the same as that of the cabinet. The shape of the door 2 ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com