Light guide and light emitting device

A technology of light-emitting device and light guide body, applied in the direction of light guide, optics, optical components, etc., can solve problems such as flicker, and achieve the effect of suppressing flicker

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

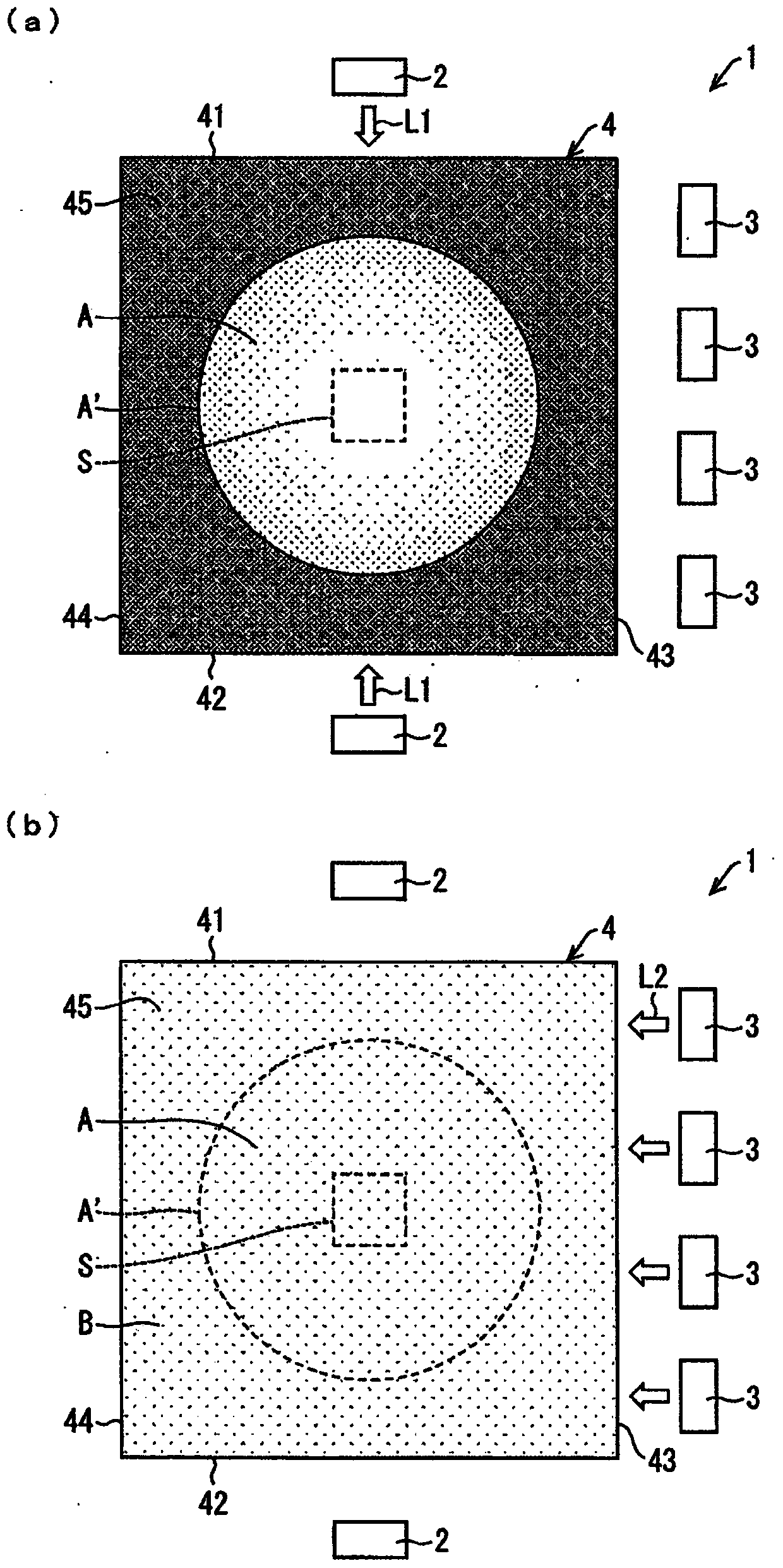

[0086] Below, based on Figure 1 to Figure 9 Embodiments of the present invention will be described. In this embodiment mode, an example of a light emitting device including the light guide of the present invention will be described.

[0087] [Structure of Light-Emitting Device 1 ]

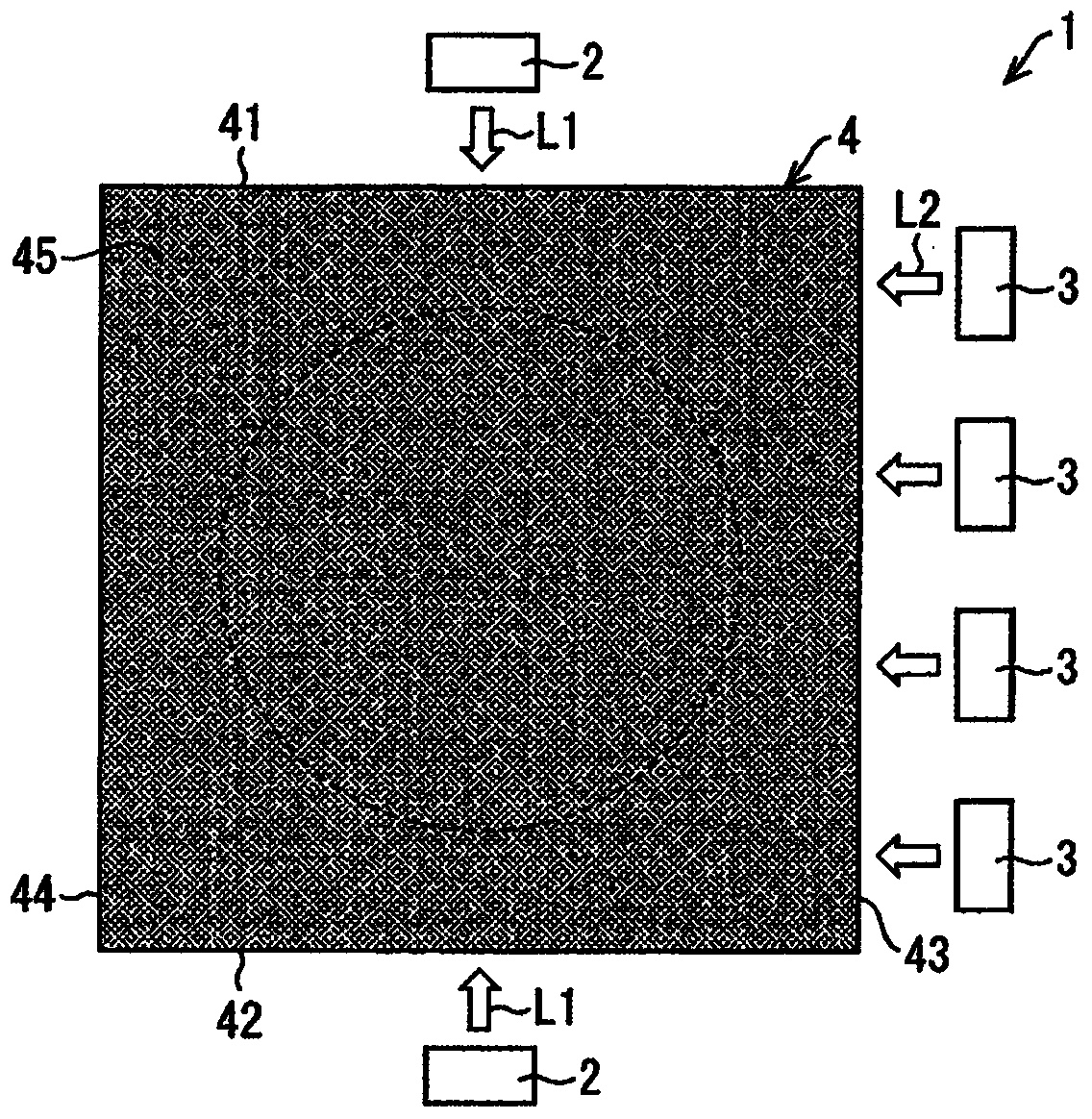

[0088] figure 1 It is a plan view showing the light emitting device 1 including the light guide plate (light guide body) 4 of the present embodiment. This light emitting device 1 is used as various surface light emitting devices such as an illuminated push button switch provided on an elevator operation panel attached to a wall surface of an elevator car, for example.

[0089] Such as figure 1 As shown, the light emitting device 1 includes a first light source 2 , a second light source 3 and a light guide plate 4 .

[0090] (first light source 2)

[0091] The first light source 2 is a light emitting element that makes light L1 incident on both side surfaces 41 and 42 of the light guide pla...

Deformed example 1

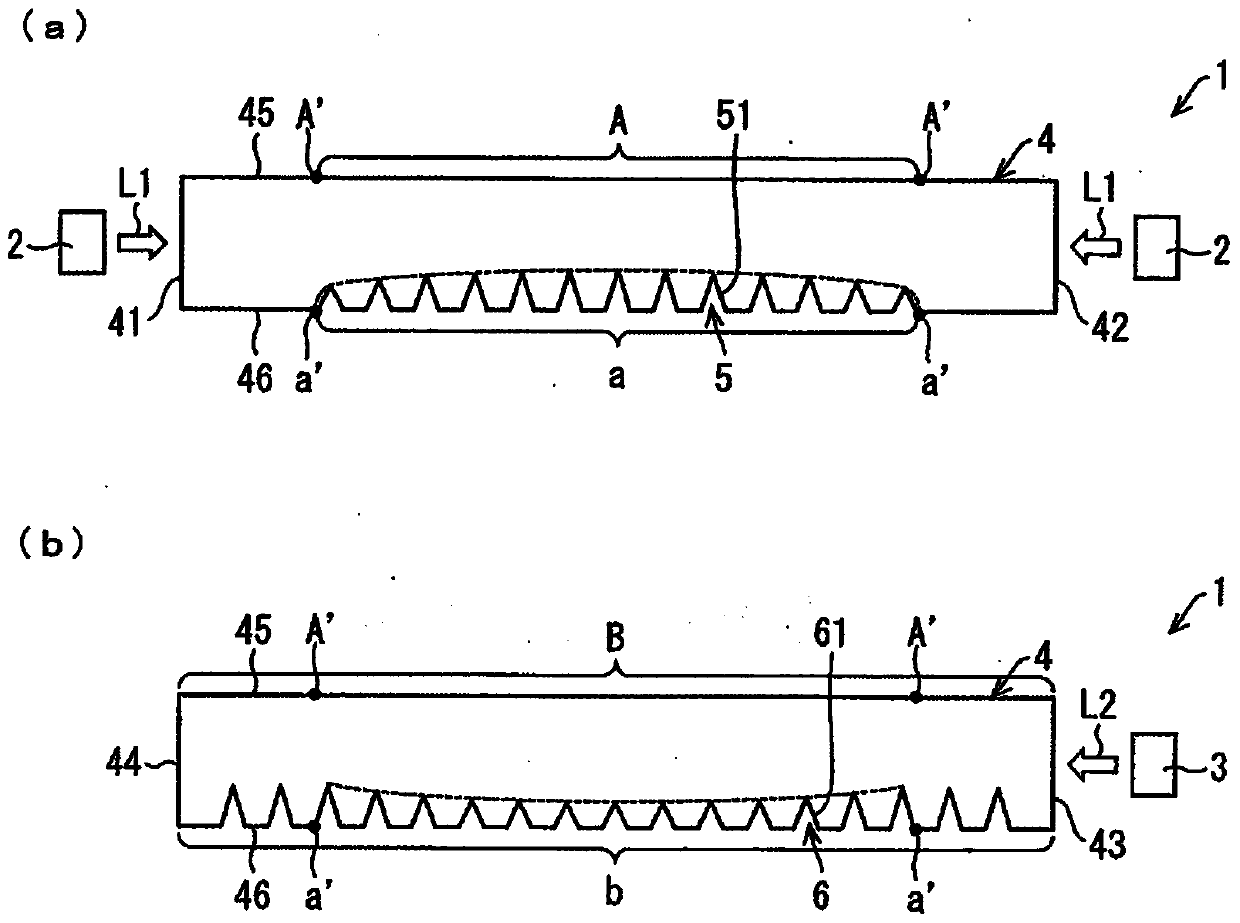

[0148] In the above description, the structure in which triangular prism-shaped patterns are formed on the back surface 46 of the light guide plate 4 as the first reflective pattern 5 and the second reflective pattern 6 has been described, but the first reflective pattern 5 and the second reflective pattern 6 The shape is not particularly limited. For example, the first reflective pattern 5 and the second reflective pattern 6 may be spindle-shaped when viewed from a direction perpendicular to the light exit surface 45 of the light guide plate 4 .

[0149] Figure 7 (a) is a perspective view of the first reflective pattern 5a, Figure 7 (b) is a plan view of the first reflective pattern 5a, Figure 7 (c) is a side view of the first reflective pattern 5a.

[0150] Such as Figure 7 As shown in (a) to (c), when viewed from the vertical direction of the light exit surface 45 of the light guide plate 4, the first reflective pattern 5a is positioned positively to the optical axi...

Deformed example 2

[0159] In addition, in the above description, the configuration in which the light L1, L2 is reflected by the first reflective pattern 5 and the second reflective pattern 6 formed on the back surface 46 of the light guide plate 4 to emit from the light exit surface 45 has been described. However, it may be configured to refract the lights L1 and L2 to emit from the light emitting surface 45 .

[0160] The refraction type light guide plate (light guide body) that refracts the light L1, L2 includes a first refraction structure that is arranged with a plurality of first refraction structures that refract the light L1 incident from the first light source 2 and emit it from the light exit surface 45. region, and the second refraction region in which the light L2 incident from the second light source 3 is refracted and emitted from the light exit surface 45 is arranged, when viewed from the vertical direction of the light exit surface 45, the second refraction region At least a part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com