Magnetic control type arc furnace transformer device

A technology for electric arc furnace transformers and magnetron reactors, which is applied in the direction of electric heating devices, electrical components, heating through discharge, etc., can solve the problem of reducing the stability of the output voltage of the power supply system, the sudden rise and fall of the voltage of the power supply system, and affecting the normal use of other users Electricity and other problems, to achieve the effect of shortening the smelting time, convenient application and operation, convenient and flexible layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific structure and application method of the present invention will be described in detail in conjunction with the accompanying drawings.

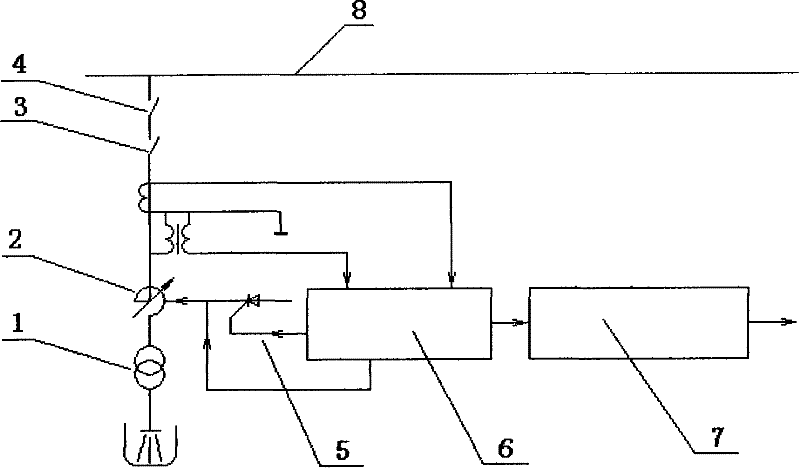

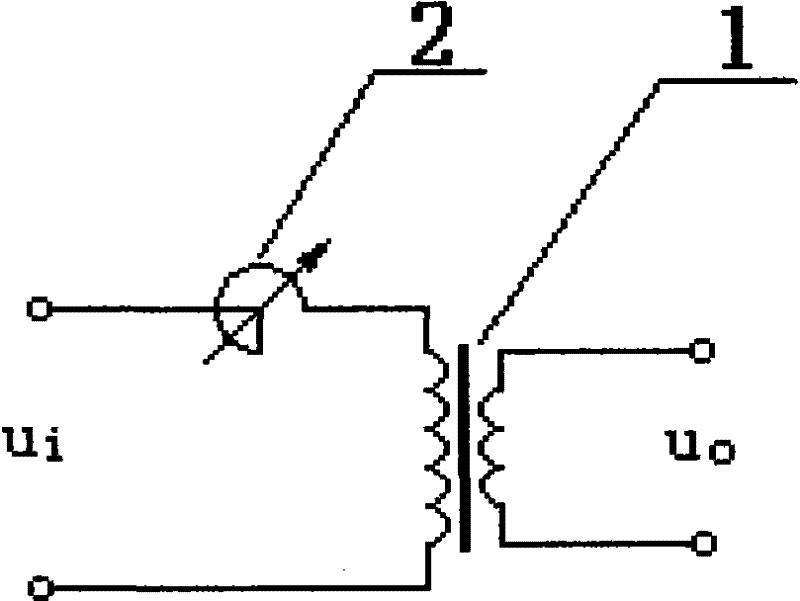

[0025] A magnetically controlled electric arc furnace transformer device, such as figure 1 and figure 2 Shown: According to the capacity of the electric arc furnace, select the electric arc furnace transformer with appropriate specifications and models, select the magnetic control reactor with appropriate specifications and models according to the capacity of the electric arc furnace, and connect the three-phase windings on the primary side of the three-phase electric arc furnace transformer 1 with the magnetic control reactor in series 2, electric arc furnace transformer 1 and magnetron reactor 2 are connected in series to the 10kV high-voltage load switch 3 in the conventional standard electric control cabinet, the high-voltage load switch 3 is connected to the isolation switch 4, and the isolation switch 4 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com