Whole-yard automatic combined scheduling method of container harbor

A joint scheduling and container technology, which is applied in the direction of instruments, data processing applications, resources, etc., can solve the problems of difficult and complex management of container terminals, and achieve the goal of rationally arranging storage yard plans, reducing container turnover, and improving operating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

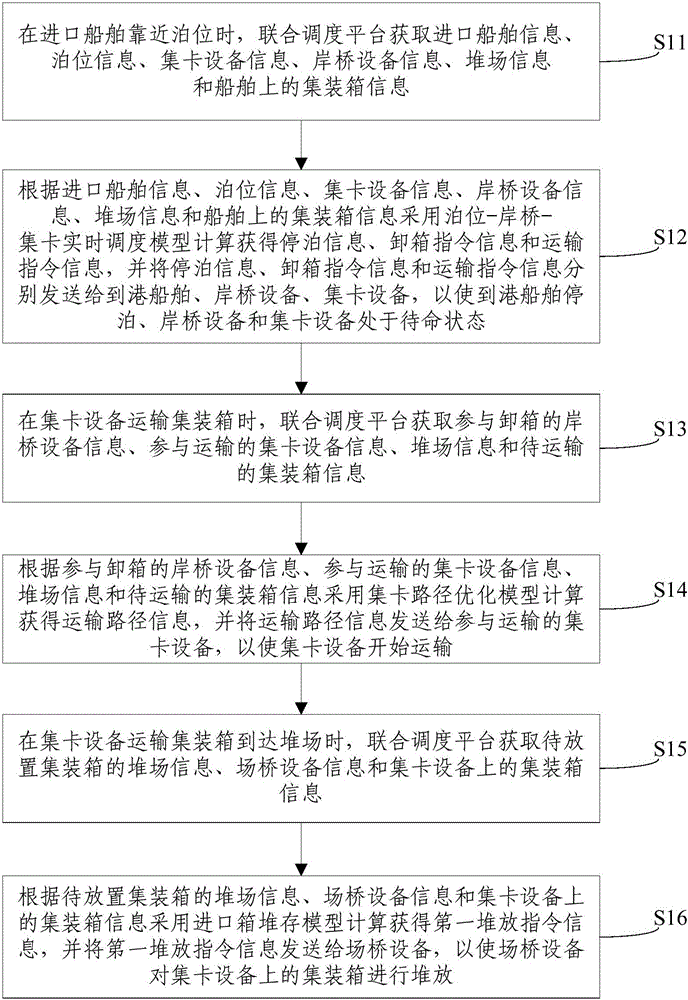

[0024] figure 1 It shows that the embodiment of the present invention provides a container terminal full-site automatic joint scheduling method, including:

[0025] S11. When the imported ship approaches the berth, the joint dispatching platform obtains the information of the imported ship, berth information, truck equipment information, quayside crane equipment information, yard information and container information on the ship.

[0026] In this step, it should be noted that, in the embodiment of the present invention, scheduling is performed on export containers. When an import ship approaches the berth, it can be understood as the import ship arrives at the port in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com