Electron Beam Welding Method of Tube and Tube Sheet in Titanium Alloy Heat Exchanger

A technology of electron beam welding and electron beam welding, which is applied in the direction of electron beam welding equipment, welding equipment, welding/welding/cutting items, etc., can solve problems such as inability to weld, achieve energy concentration, reliable welding, and improve overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

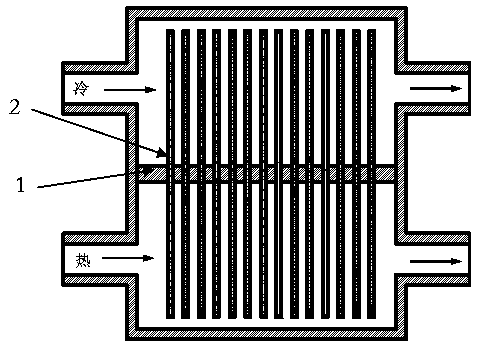

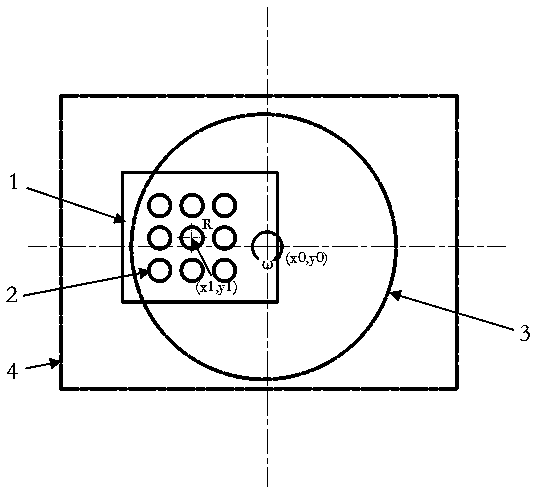

[0029] In this embodiment, the material of the tube sheet 1 and the tube 2 in the heat exchanger is TA2, and there are 9 tubes 2 in total. The specifications and spacing of the tubes 2 are the same. The inner diameter D2=11mm, the pipe radius R refers to half of the outer diameter, that is, R=7.5mm, the distance between the pipes refers to the distance between the centers of the two pipes, and the minimum distance d between the centers of two adjacent pipes =20mm, then, the minimum distance k=d-2R=d-D1=5mm between the outer walls of two adjacent tubes, and the length of the tube protruding from the tube sheet is 500mm. In this embodiment, select L= , the specific welding process is:

[0030] (1) Clean the tube 2 and the tube sheet 1, and use acetone and alcohol solvents to ultrasonically clean them to remove oil stains;

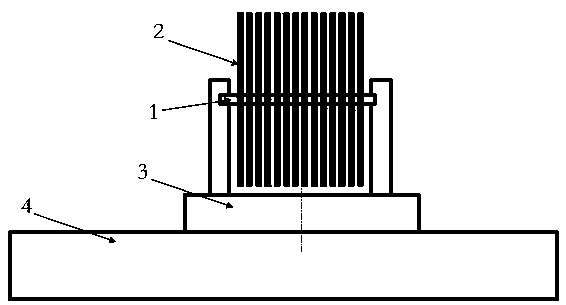

[0031] (2) Assemble the tube 2 and the tube sheet 1, the assembly structure is as follows figure 2 As shown, ensure that the tube wall is perpendicular ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com