Six-axis robot with manipulator assemblies arranged on small arms

The technology of a manipulator assembly and a six-axis robot is applied in the field of robotics and can solve the problems of falling off the workpiece, grasping the workpiece, and keeping the movement range of multiple claws consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

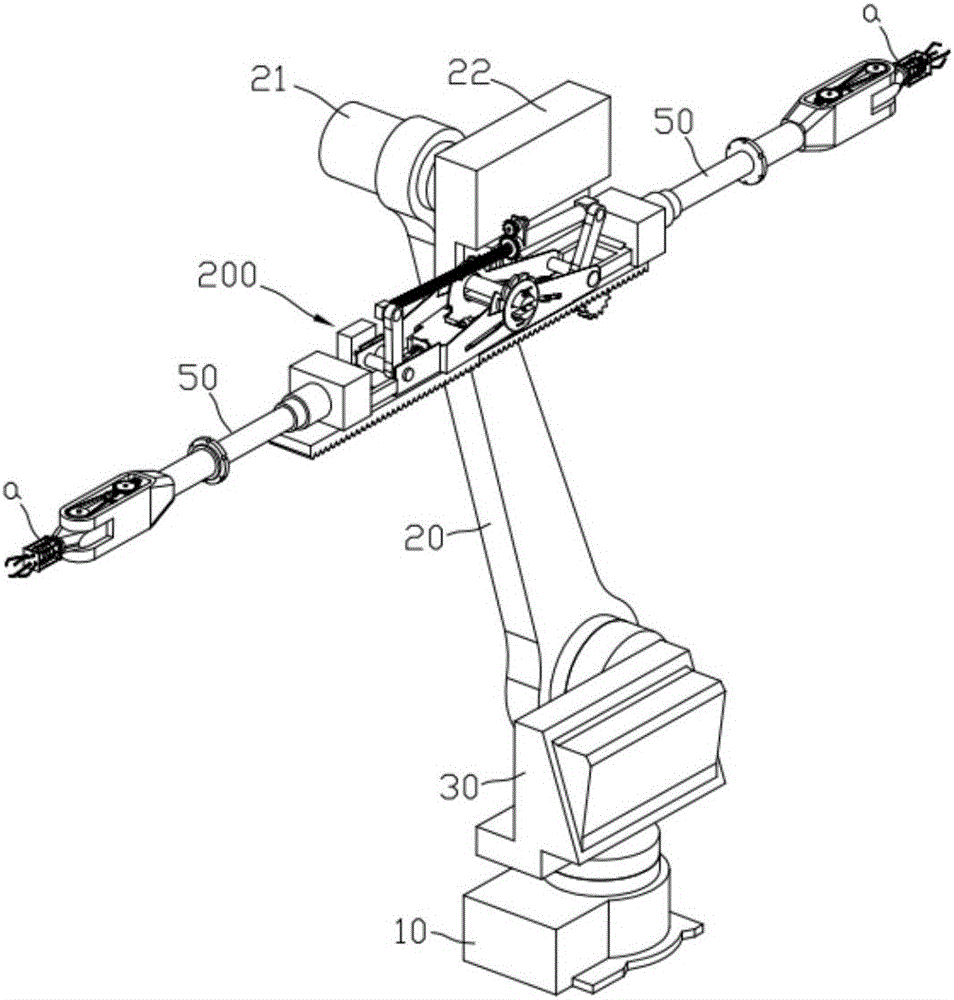

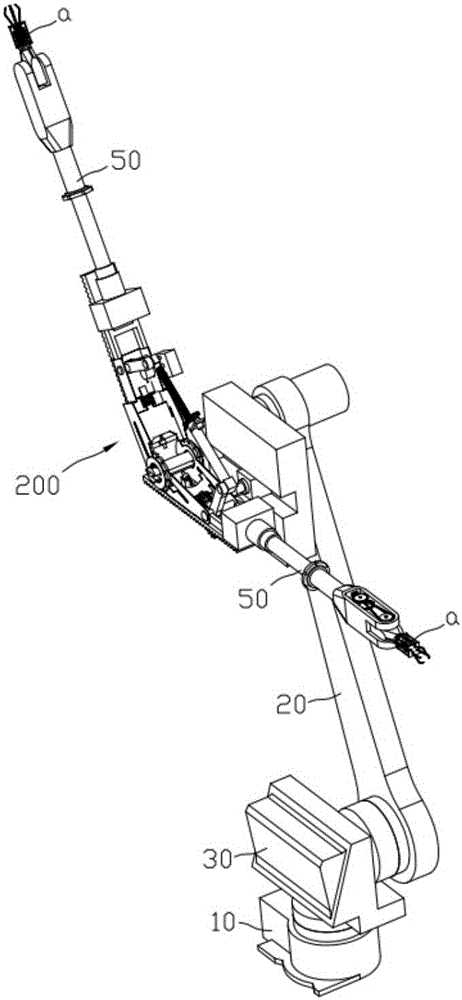

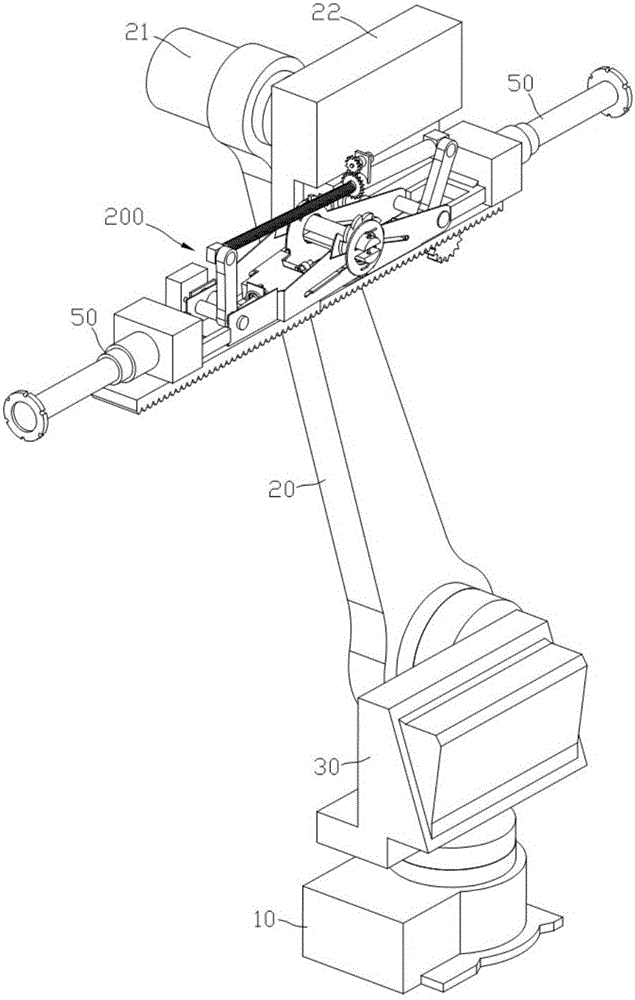

[0053] Such as figure 1 , figure 2 , a six-axis robot with a manipulator assembly on the forearm, including a base body 10, a waist swivel part 30 pivotally connected to the base body, a big arm 20 pivotally connected to the waist swivel part, and a Forearm 50, the manipulator assembly a installed on the forearm, the waist swivel part rotates around the base body, and the big arm rotates around the waist swivel part.

[0054] There are two forearms, namely the first forearm and the second forearm, and the two forearms are installed on the main arm through the split mechanism 200 . combine Figure 3 to Figure 7 , the split mechanism includes a sliding base 22, a first split bracket 24, a reel 25 fixed on the first split bracket, a ratchet wheel fixed at both ends of the reel, and a second split bracket 27 pivotally connected to the reel 1. Connect the telescopic rod 28 of the first split bracket and the second split bracket; the second split bracket is provided with a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com