Automatic casing framing system

An automatic and frame-mounting technology, which is applied in the direction of packaging, transportation and packaging, and individual objects, can solve the problems of low packaging efficiency, time-consuming and labor-consuming, and disconnected casings, and achieve the advantages of convenient operation, reduced production costs, and reduced labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] Example 1

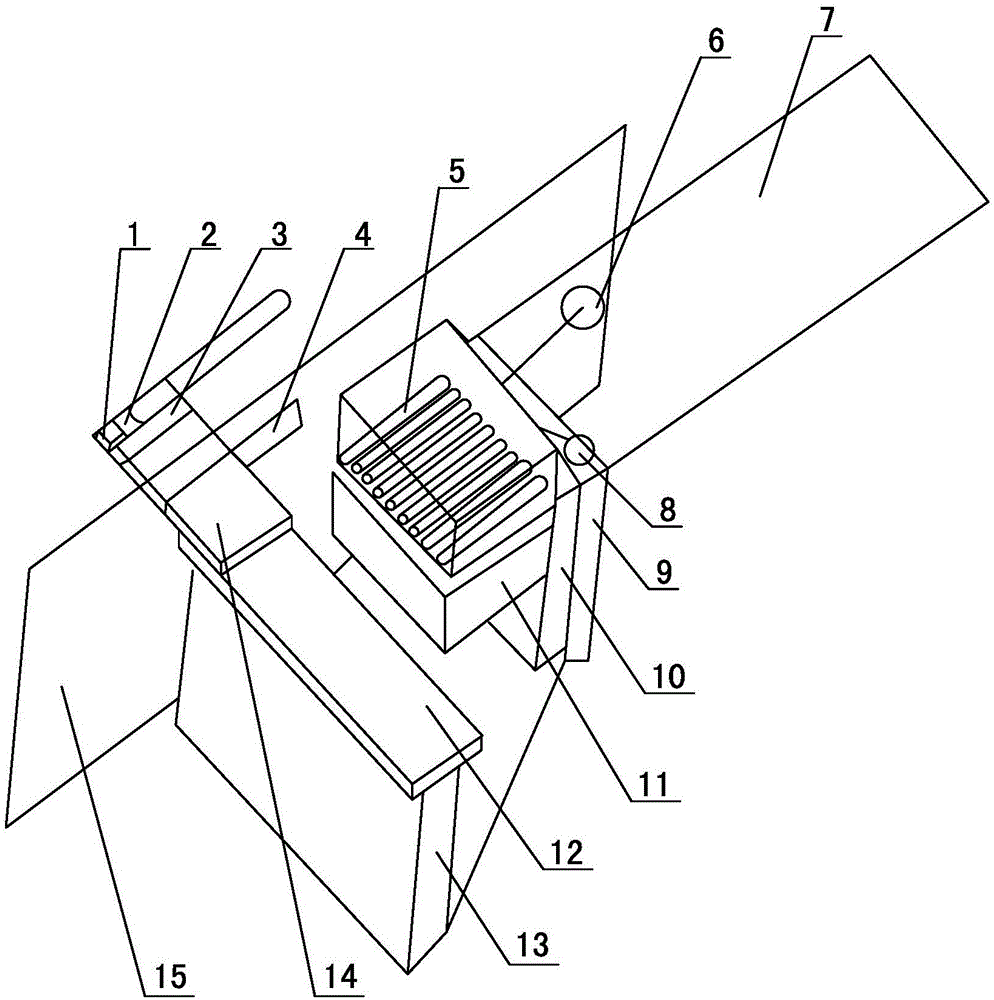

[0024] Such as figure 1 As shown, the automatic casing framing system includes a transmission device and a lifting device. The transmission device includes a sliding table 12, a tray 14, a connecting block 3 and a bracket 2. A supporting table 13 is provided under the sliding table 12, and the sliding table A pallet 14 is provided above 12, one side of the pallet 14 is slidably connected with a connecting block 3, one side of the connecting block 3 is slidably connected with a bracket 2, and one end of the bracket 2 is provided with a limit block 1; the lifting device includes a material frame 11 , The lifting platform 10 and the side plate 9, the lifting platform 10 and the side plate 9 are slidingly connected, one end of the material frame 11 is connected with the lifting platform 10; the material frame 11 is provided with a support frame 5.

[0025] The bracket 2 is a reversible structure.

[0026] A conveying device is provided on one side of the side plate 9....

Example Embodiment

[0034] Example 2

[0035] The other structure is the same as in embodiment 1, the difference is:

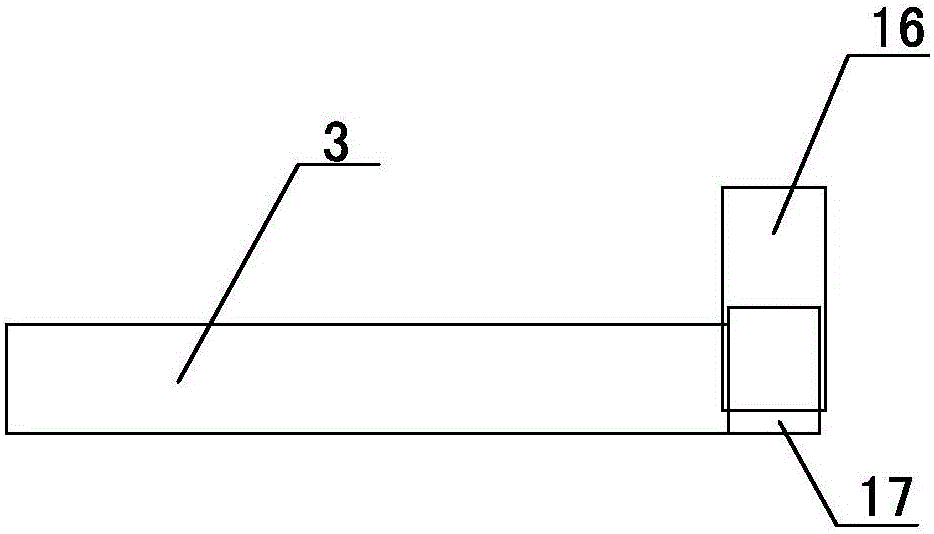

[0036] A shaft 17 is provided on one end of the connecting block 3, and a rotating baffle 16 is provided on the shaft 17. When the bracket 2 places the casing on the support frame 5, the baffle 16 is rotated to a position that can block one end of the casing. Then the bracket 2 retreats, achieving the purpose of retreating the bracket 2 and leaving the casing on the support frame 5.

[0037] The support frame 5 is provided with a track for the carriage 2 to slide, which reduces the friction between the carriage 2 and the support frame 5 and increases the freedom of the carriage 2 to advance and retreat.

[0038] When the described automatic casing framing system works, the other processes are the same as those in Example 1, except for:

[0039] Rotate the baffle plate 16 along the shaft 17 to a position that can block one end of the casing, then the connecting block 3 does not move, the b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap