Energy-saving air-seal pneumatic conveying pump

A pneumatic conveying and energy-saving technology, which is applied in the field of energy-saving air-sealed pneumatic conveying pumps, can solve the problems of affecting the conveying distance, fast wear of air lock, and high cost of use, so as to reduce the cost of use, avoid pressure backlash, and convey distance far effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

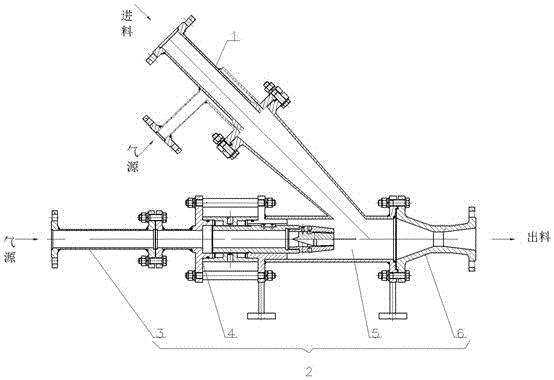

[0014] refer to figure 1 , the present embodiment comprises jet type pneumatic conveying pump 2, and jet type pneumatic conveying pump 2 comprises storage room 5, and one end of storage room 5 is provided with the gas source connection pipe 3 that communicates with storage room 5, and the other end is provided with storage room 5 and communicates with. Venturi tube 6; one side of the storage chamber 5 is provided with a nozzle 4, and the other side of the storage chamber 5 is provided with a gas-sealed jet 1 communicated with the storage chamber 5, and the gas-sealed jet 1 is located at the side of the storage chamber 5 above. The centerline of the air-sealed ejector 1 forms an included angle of 45° with the centerline of the jet pneumatic conveying pump 2 . The gas-sealed ejector 1 is made of ordinary Q235 steel.

[0015] The gas-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com