Tire tread prescription of ultra-wearproof graphene material for full steel tire

A graphene and ultra-wear-resistant technology, which is applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc., can solve the problems of shortened service life, crown blasting, etc., to prolong the overall life, improve wear resistance, Reasonable and practical design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

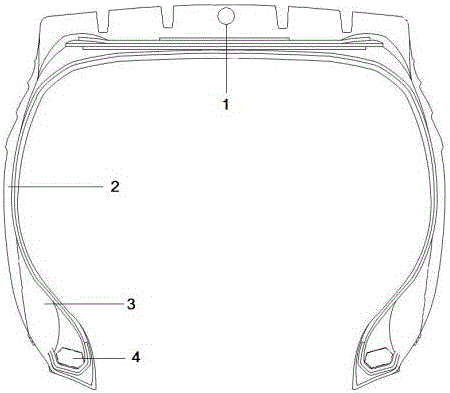

[0009] Such as figure 1 As shown, the tire crown is the grounding part of the tire, which is directly contacted with the ground to cause wear. The tire crown 1 is provided on the belt steel wire part, and the sidewall 2 is connected to the rubber core 3, and the rubber core 3 is connected to the bead ring 4. The preparation of the formula of the present invention includes the following steps: the first step: using 1.5-2.5 parts of graphene as the key material of the formula. Step 2: Mix 80 parts of natural rubber, 10 parts of butadiene rubber, 10 parts of styrene-butadiene rubber, and 45 to 55 parts of carbon black, which complement each other in improving the wear resistance of rubber materials. The formula of the present invention adopts natural rubber, butadiene rubber, and styrene-butadiene rubber system with excellent wear resistance, and a graphene material with super wear resistance is newly added, and its perfect proportion combination fundamentally improves the tradit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com