Preparation method of rare-ginsenoside-Rg3-rich black ginseng

A ginsenoside and rare technology, applied in the field of preparation of black ginseng, can solve the problems of complex production process, unstable Rg3 content, time-consuming and labor-intensive, etc., and achieve the effects of small loss of nutrients, low cost, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0023] Example 1, take 100 kg of glutinous rice soaked and cooked, add 0.2 kg of Aspergillus oryzae, then add 1.2 kg of natural yeast, ferment at 37°C for 48 hours, take the glutinous rice fermentation liquid for later use;

[0024] Take 5 kg of schisandra and 1 kg of hawthorn, wash and crush them, add 30 kg of glutinous rice fermentation liquid, add 0.072 kg of plantaractobacillus, and ferment in a fermenter at a constant temperature of 36°C for 80 hours to obtain a fermentation liquid.

[0025] Take 2 kg of ginseng and wash it, put it in a fermenter, add 6 kg of ginseng fermentation broth, and ferment at a constant temperature for 96 hours at 37°C.

[0026] The fermented ginseng is placed in a high-temperature rotary steamer, steamed with water vapor at 80°C for 4 hours, and then dried in a vacuum dryer for 2 hours. Repeat the steaming and drying steps twice to get 1.2kg rich in rare ginsenoside Rg 3 black ginseng products.

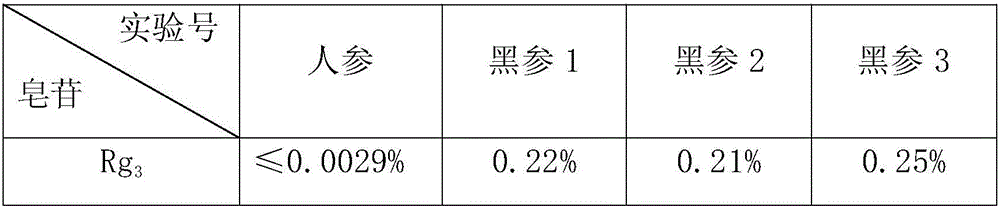

[0027] After testing, the ginsenoside Rg in the...

example 2

[0028] Example 2, get 100 kilograms of glutinous rice soaked and cooked, insert 0.4 kilograms of Aspergillus oryzae, insert 1.5 kilograms of natural yeast, ferment 36 hours under the condition of 39 ℃, take its glutinous rice fermentation liquid for later use;

[0029] Take 5 kg of schisandra and 2 kg of hawthorn, wash and crush them, add 49 kg of glutinous rice fermentation liquid, add 56 g of plantaractobacillus according to the total weight of the feed liquid, and ferment at a constant temperature for 96 hours in a fermenter at 39 ° C to obtain a fermented liquid.

[0030] Take 3 kg of ginseng and wash it, put it in a fermentation tank, add 6 kg of ginseng fermentation broth, and ferment at a constant temperature for 48 hours at 38°C.

[0031] The fermented ginseng was placed in a high-temperature rotary steamer, steamed for 6 hours at 100°C, and then dried in a vacuum dryer for 4 hours. Repeat the steaming and drying steps twice to get 3.2kg rich in rare ginsenoside Rg 3...

example 3

[0033] Example 3, get 100 kilograms of glutinous rice soaked and cooked, add 0.5 kilogram of Aspergillus oryzae, insert 1.1% kilogram of natural yeast, ferment 30 hours under 38 ℃ of conditions, get its glutinous rice fermentation liquid for subsequent use;

[0034] Take 5 kg of schisandra and 1.5 kg of hawthorn, wash and crush, add 52 kg of glutinous rice fermentation liquid, add 40 g of Lactobacillus plantarum according to the total weight of the feed liquid, and ferment in a fermenter at a constant temperature of 38 ° C for 90 hours to obtain ginseng fermentation liquid.

[0035] Take 300 grams of ginseng and wash it, put it in a fermenter, add 1.5 kg of fermentation broth, and ferment at a constant temperature for 45 hours at 35°C.

[0036] The fermented ginseng is placed in a high-temperature rotary steamer, steamed with water vapor at 95°C for 5 hours, and then dried in a vacuum dryer for 3 hours. Repeat the steaming and drying steps twice to get 180g rich in rare ginse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com