A plastering arm of a wall automatic semi-automatic plastering machine

A semi-automatic, plastering machine technology, applied in the field of plastering arms, can solve the problems of poor mortar adhesion, poor adaptability, and poor plastering effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

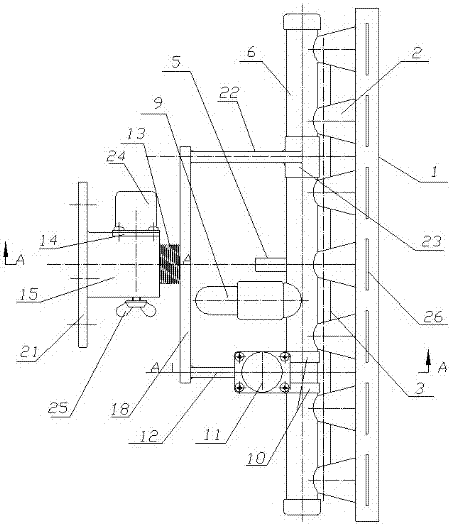

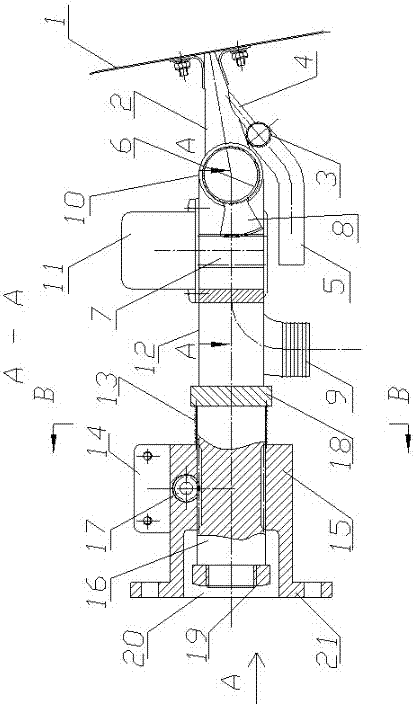

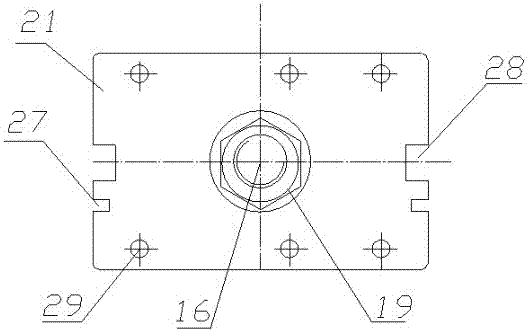

[0015] Such as Figure 1~Figure 5 It is a structural diagram of a specific embodiment of the present invention. From the figure, it can be seen that the plastering arm of the present invention includes a special-made plastering board (another application) and a plastering arm frame mechanism of a wall automatic semi-automatic plastering plastering machine. The plate surface 1 of the plastering board is rectangular, and the handle on the back side along the length direction is an ash delivery pipe. The ash delivery pipe is provided with several duckbills perpendicular to the ash delivery pipe along the length direction, and each duckbill pipe The flat outlet is connected to the corresponding mortar outlet 26 on the center line of the length direction of the rectangular plastering board surface 1, and one side of each duckbill tube 2 is connected with an air blowing pipe 4 towards the outlet direction, and each air blowing pipe 4 is connected in parallel. On the main air pipe 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com