Nozzle device and spraying equipment

A nozzle device and nozzle technology, applied in the direction of spray device, building, building structure, etc., can solve the problems of large size of nozzle device, inconvenient spraying operation, affecting spraying quality, etc., to achieve high spraying efficiency, good wall adaptability, The effect of improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

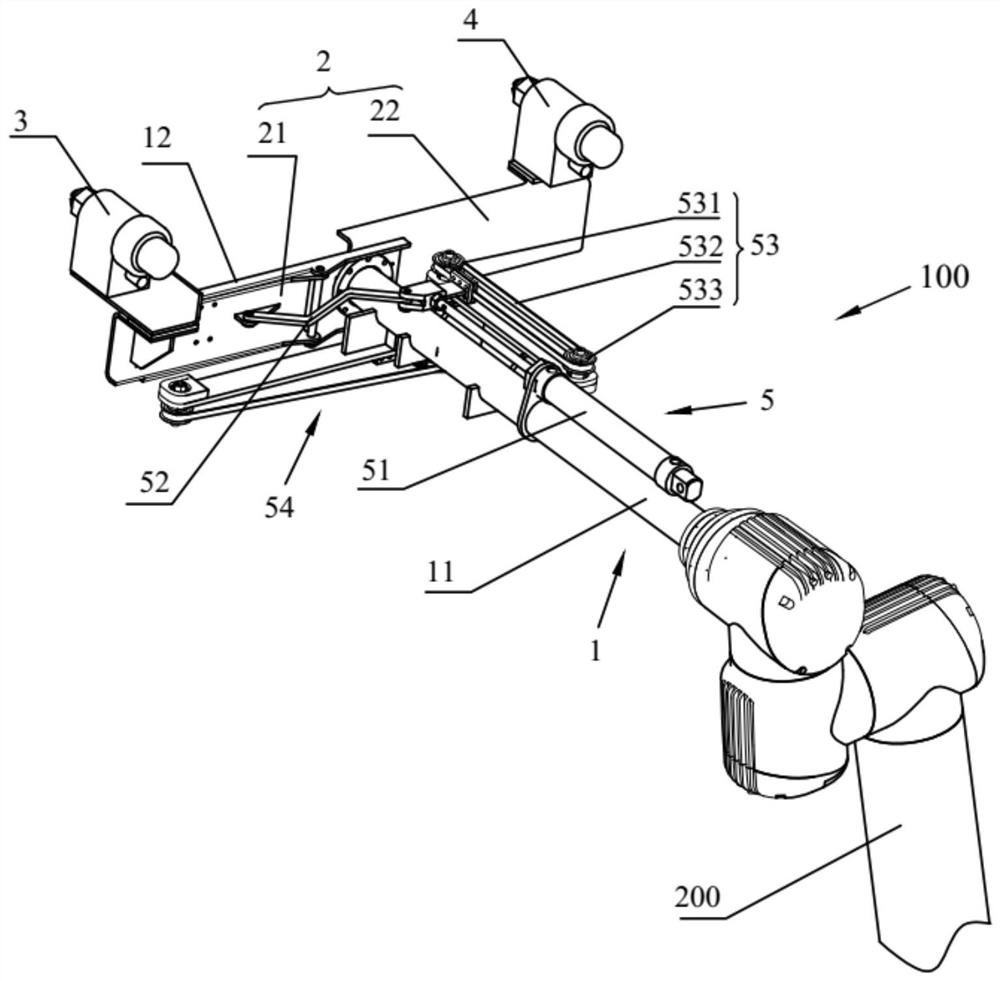

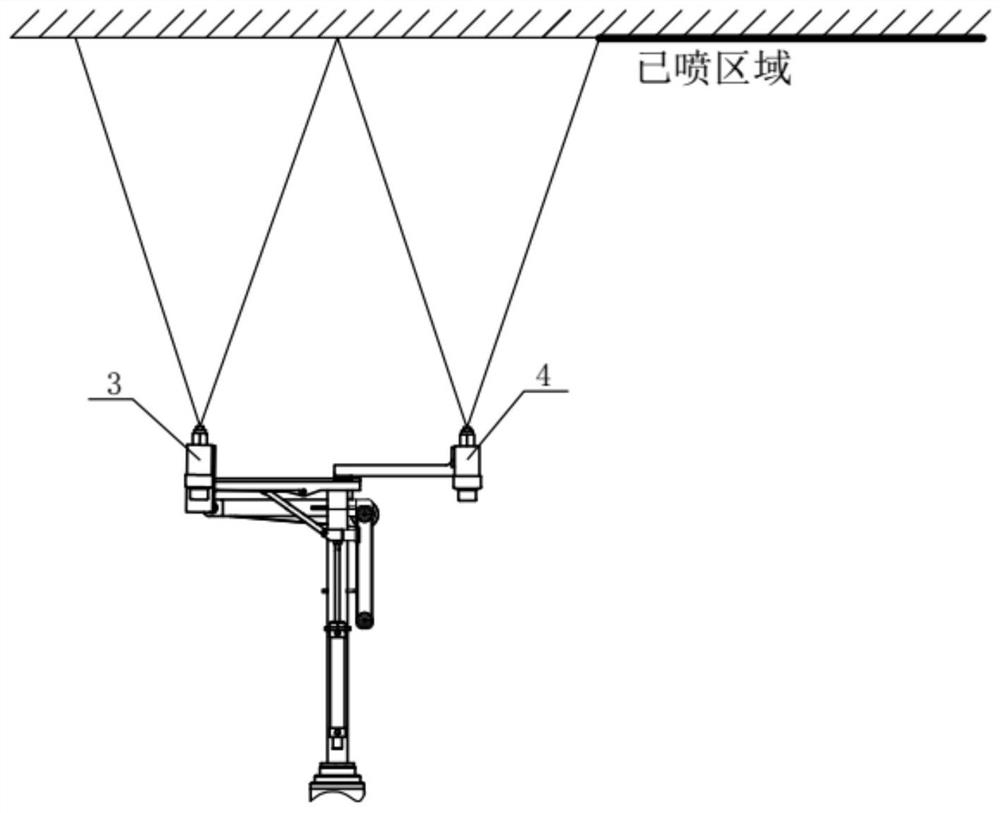

[0052] Such as Figure 1-Figure 9 As shown, this embodiment provides a nozzle device 100, including a mounting frame 1, a nozzle assembly and a driving mechanism 5, the nozzle assembly includes a fixed frame 2, a first nozzle 3 and a second nozzle 4, and the fixed frame 2 is movably arranged On the mounting frame 1, the first nozzle 3 and the second nozzle 4 are all arranged on the fixed frame 2; the driving mechanism 5 is arranged on the mounting frame 1, and the output end of the driving mechanism 5 is connected with the fixed frame 2 in transmission, and the driving mechanism 5 can Drive the fixed frame 2 to overlap and unfold the mounting frame 1, and make the spraying direction of the first nozzle 3 intersect with the spraying direction of the second nozzle 4 when the fixed frame 2 and the mounting frame 1 are in a stacked state; when the fixed frame 2 When the installation frame 1 is in the unfolded state, the spraying direction of the first nozzle 3 is the same as that ...

Embodiment 2

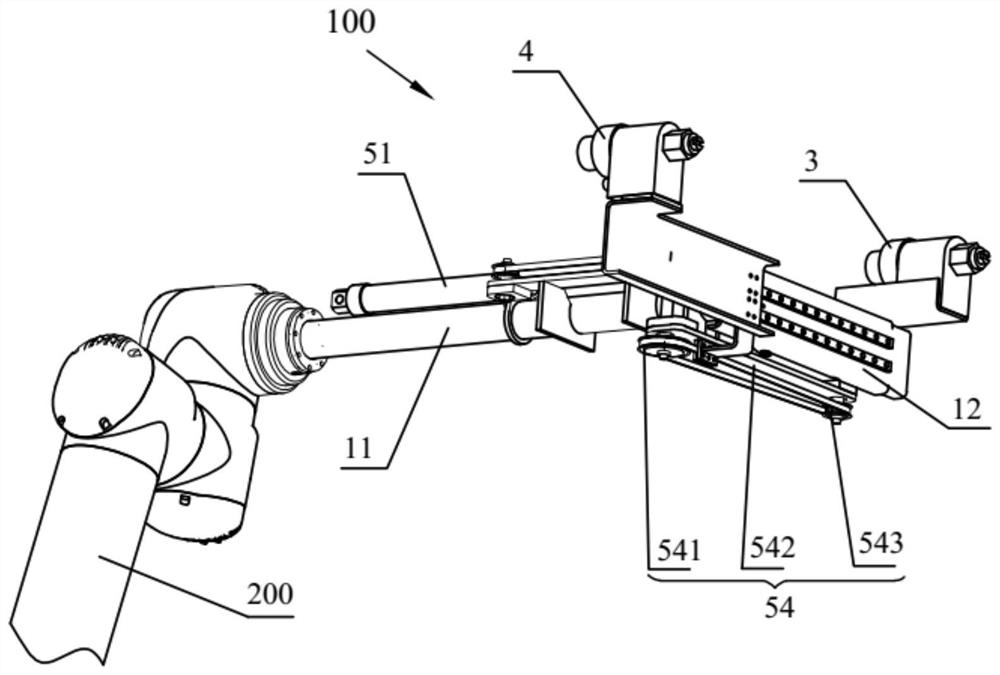

[0078] Such as Figure 10-Figure 11 As shown, this embodiment provides an optional nozzle device 100, which differs from Embodiment 1 in that:

[0079] The installation frame 1 only includes the first installation part 11 , does not include the second installation part 12 , and the driving mechanism 5 is installed on the first installation part 11 .

[0080] Further, the fixed frame 2 includes a rotary part 23 and a rotary part 24, the rotary part 23 is rotatably arranged on the mounting frame 1 (ie, the first mounting part 11), and the first nozzle 3 is arranged on the rotary part 23; the rotary part 24 Rotatably arranged on the rotating member 23, the second nozzle 4 is arranged on the rotating member 24; the driving mechanism 5 can drive the rotating member 23 to rotate relative to the mounting frame 1 and overlap with the mounting frame 1, and drive the rotating member 24 relative to the The rotating member 23 rotates so that the spraying direction of the second nozzle 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com