Engine intake manifold with cooler inside and high tightness

A technology of intake manifold and cooler, which is applied in the direction of machines/engines, internal combustion piston engines, engine components, etc., and can solve the problems of not fully utilizing the heat exchange function of the cooler, too many sealing parts, and large sealing surface. Achieve the effect of light weight, high heat exchange efficiency and small sealing surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

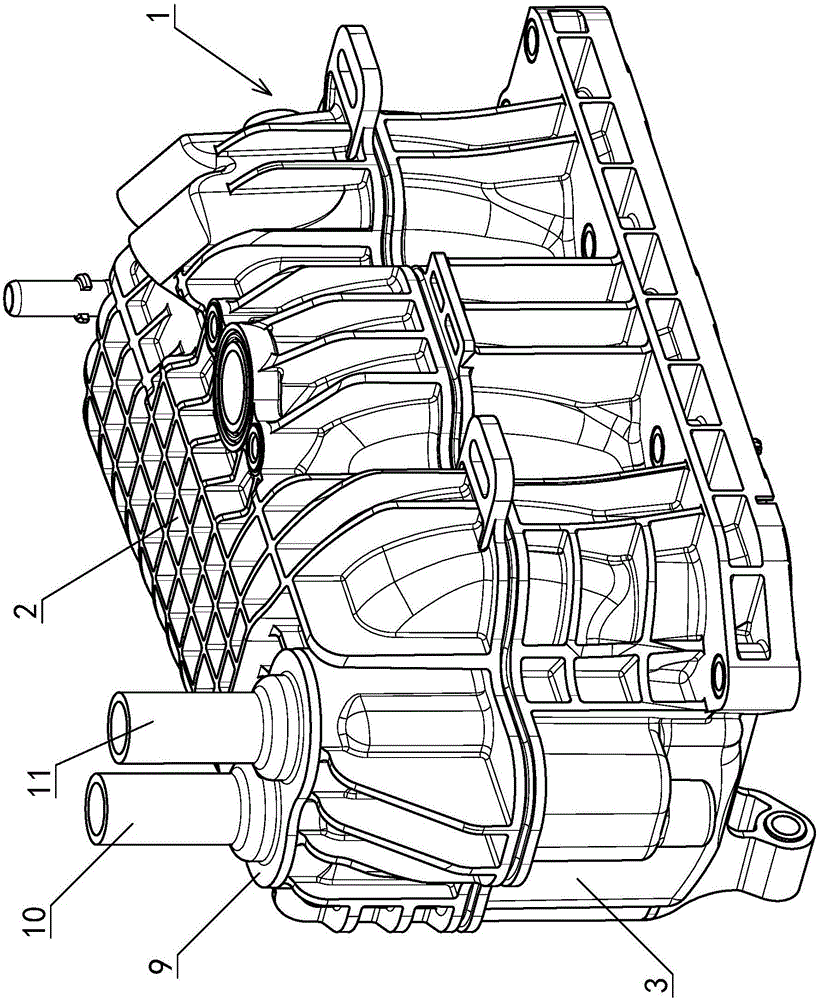

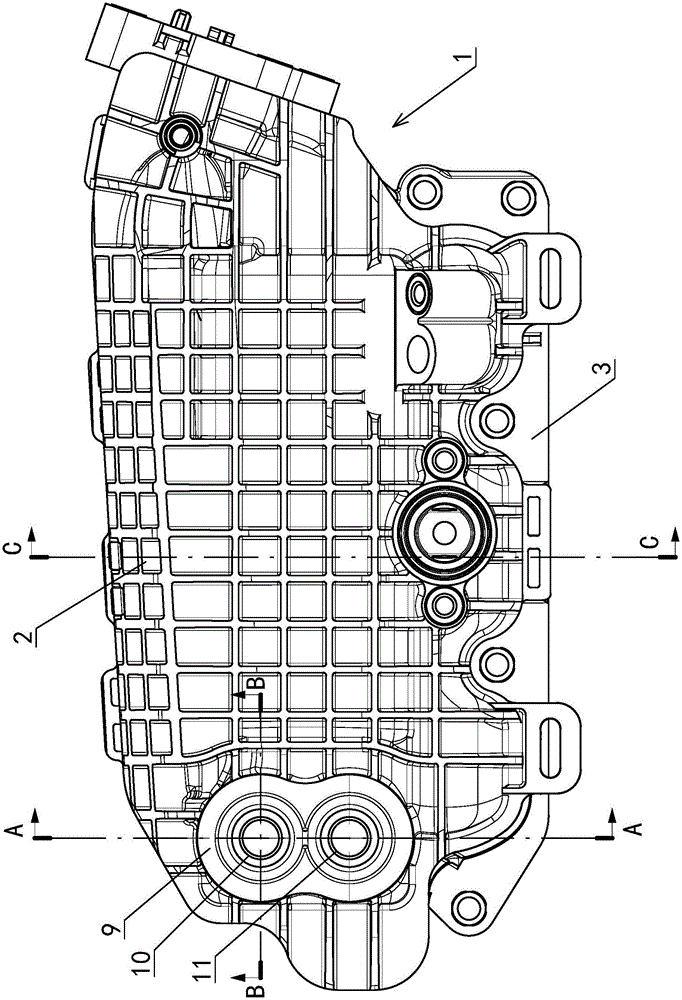

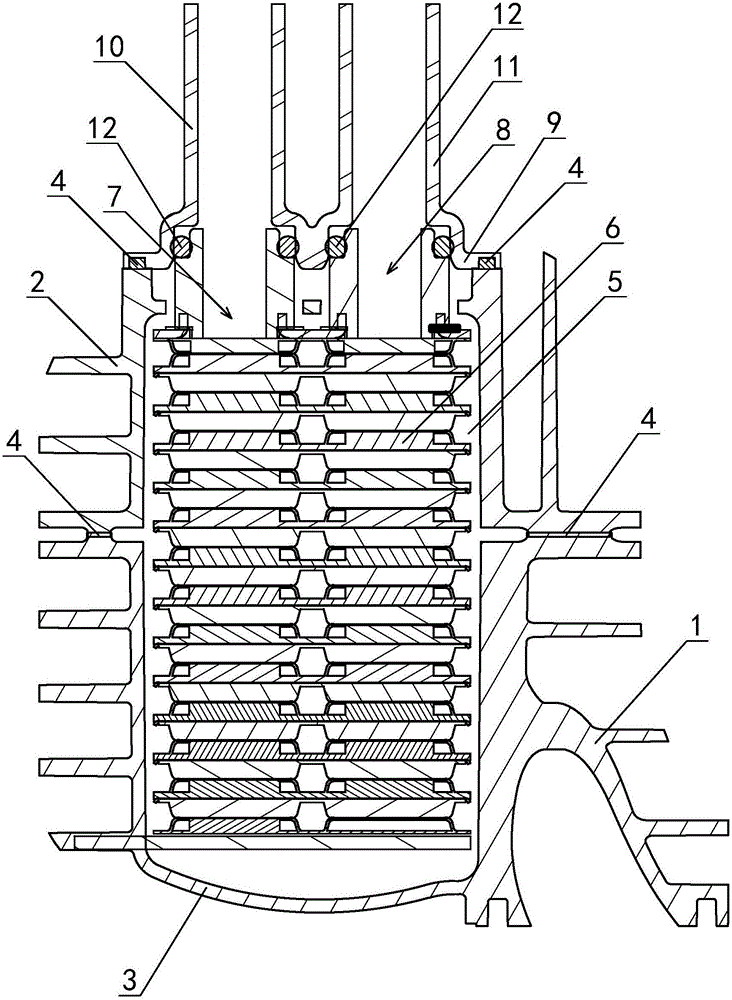

[0025] Example: see attached Figure 1~5 As shown, an engine intake manifold with a built-in cooler and high sealing performance has a casing 1, which includes an upper casing 2 and a lower casing 3; the upper casing 2 and the The lower casing 3 is connected by a welding structure 4, forming an assembly chamber 5 formed between the two, the assembly chamber 5 is used for the assembly and accommodation of the cooler 6, and the cooler 6 connects the assembly chamber 5 Separated into two independent air chambers; the cooler 6 includes a water inlet 7 and a water outlet 8 for cooling liquid, and the water inlet 7 and the water outlet 8 protrude from the upper casing 2; the cooling The interior of the device 6 is provided with a coolant flow channel (not shown in the figure) that communicates with the water inlet 7 and the water outlet 8 .

[0026] The casing 1 also includes a coolant guide cover 9, which is covered on the upper casing 2 and is sealed and connected with the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com