Direct-reflux rapid switching device for large-scale environment wind tunnel

A fast switching and environmental technology, applied in measurement devices, instruments, aerodynamic tests, etc., can solve problems such as the inability to connect the intake and exhaust ports, the large space occupied by the wind tunnel, and the heavy weight of the corner section.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

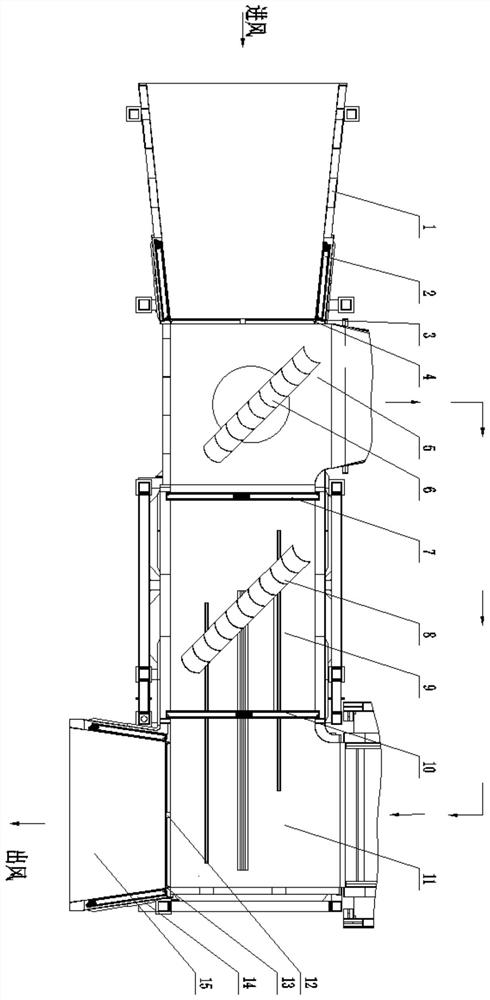

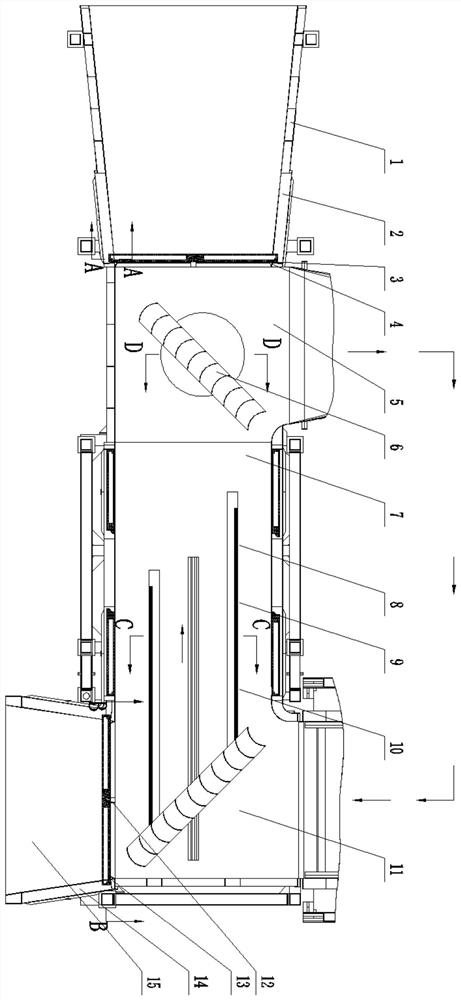

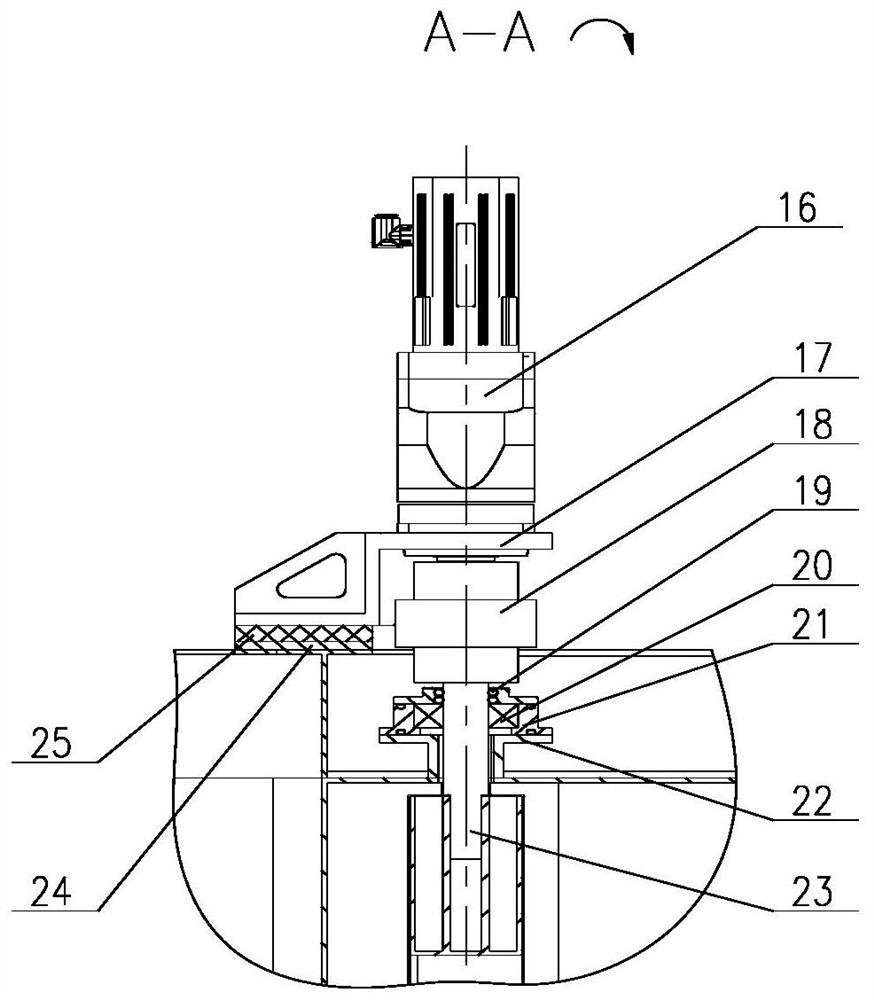

[0029] Attached below Figure 1-6 The present invention is further described with embodiment:

[0030] A direct-return fast switching device for a large-scale environmental wind tunnel, comprising an intake section 1, a second corner section 5, a straight section 9, a first corner section 11, and an exhaust section 15 welded in sequence, the intake section 1, The second corner section 5, the straight section 9, the first corner section 11 and the exhaust section 15 are respectively provided with a split sealing working door I2, a split working door I7, a split working door II10 and a split sealing working door II14 , when the four working doors are fully opened, the air flow surface is flush with the flow channel of the cave body. When conducting the direct current test, the airflow enters the flow channel through the inlet section 1 and the second corner section 5, and is discharged into the atmosphere through the first corner section 11 and the exhaust section 15, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com