Symmetrical spiral linear valve piezoelectric pump

A helical piezoelectric pump technology, applied in the direction of pumps, pump components, variable capacity pump components, etc., can solve the problems of high cost, poor followability and cut-off performance, complex structure of valve piezoelectric pumps, etc., and achieve cost Low, good followability, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

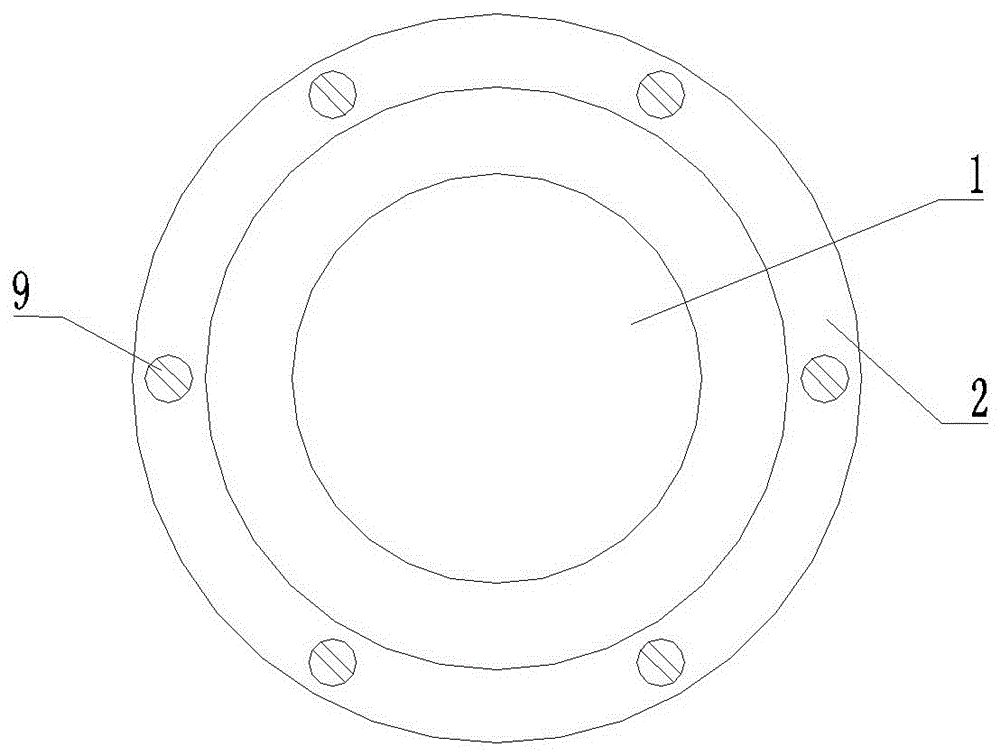

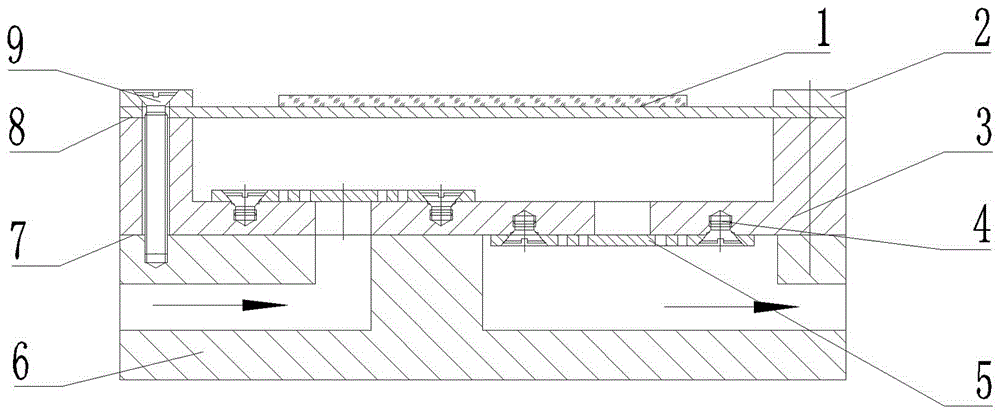

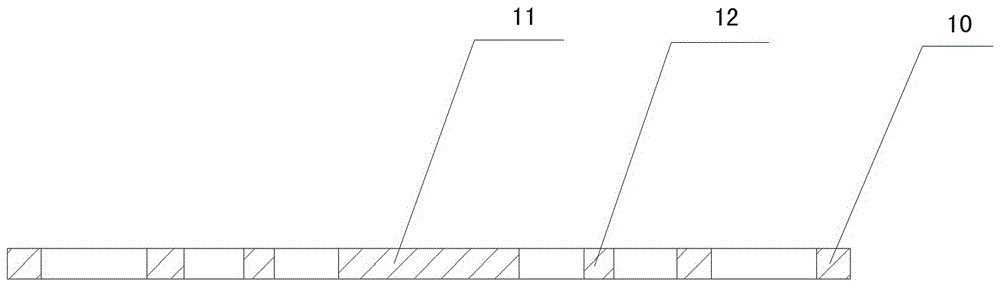

[0019] according to figure 1 , figure 2 , image 3 , Figure 4 As shown, a symmetrical helical valve piezoelectric pump of the present invention includes a piezoelectric vibrator 1, a pump cover 2, a valve seat 3, a screw 4, a pump seat 6, a sealing ring 7, a sealing ring 8, and a screw 9. The pump The top of the seat 6 is provided with a pump cover 2, the upper end of the pump seat 6 is a valve seat 3, a sealing ring 7 is provided between the valve seat 3 and the pump seat 6, a sealing ring 8 is provided between the valve seat 3 and the pump cover 2, and the valve seat 3 There is a piezoelectric vibrator 1 on the top, the piezoelectric vibrator 1 is set between the valve seat 3 and the pump cover 2, and the piezoelectric vibrator 1 and the pump cover 2, the valve seat 3 and the pump seat 6 are connected by screws 9 Fixedly connected, a pair of mutually inverted symmetrical helical check valves 5 of a simply supported beam structure are respectively installed at the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com