Naked-eye three-dimensional printing product and manufacturing method thereof

A naked-eye three-dimensional, printed matter technology, applied in optical components, optics, instruments, etc., can solve the problem that the three-dimensional printed matter cannot see the three-dimensional effect, and achieve the effect of remarkable all-round three-dimensional effect, broad market application prospect and good anti-counterfeiting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

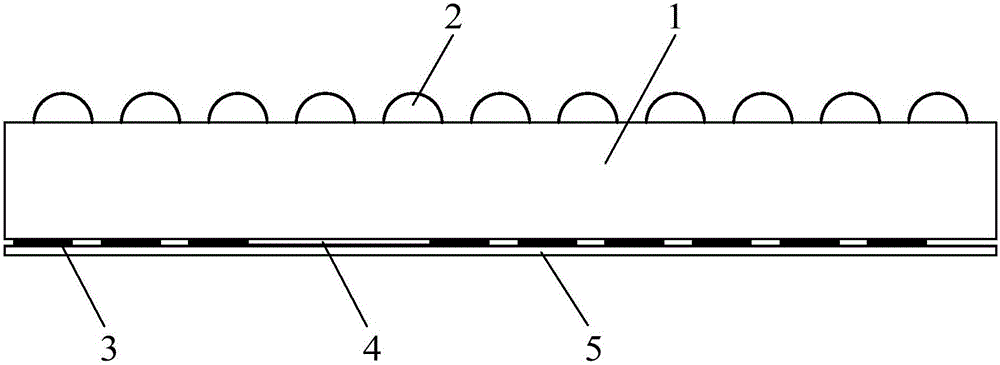

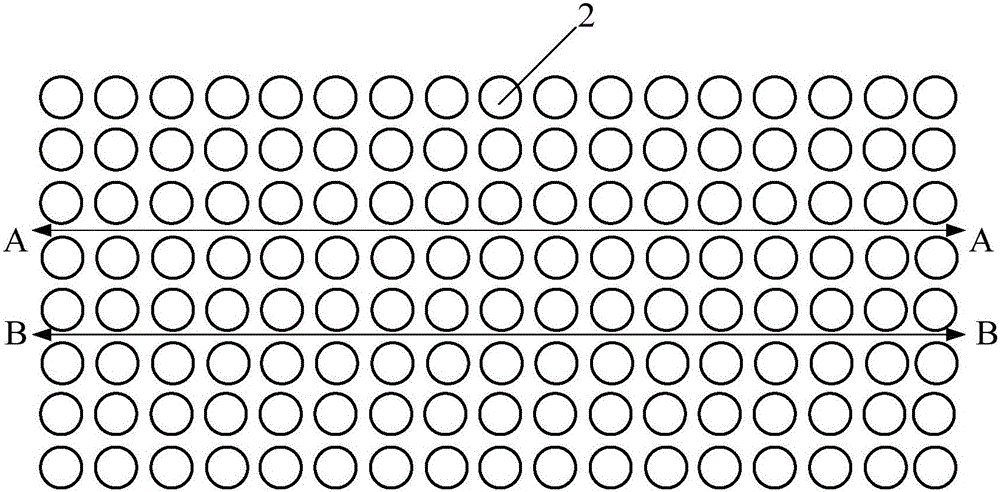

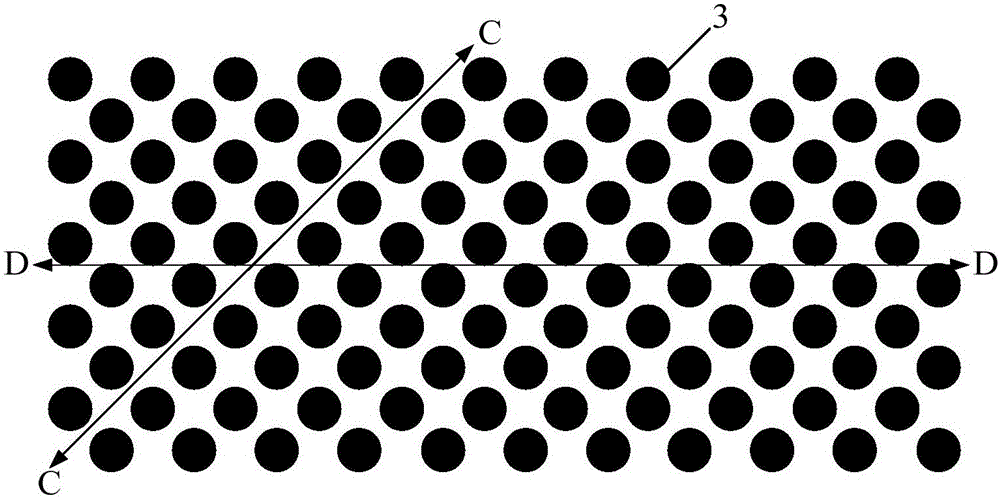

[0039] Such as Figure 1-3 As shown, the naked eye three-dimensional printed matter provided by the embodiment of the present invention includes: a transparent sheet 1, a micro lens array layer is arranged on the front of the transparent sheet 1, and a micro graphic array layer and a macro pattern layer are arranged on the back of the transparent sheet 1 4. A protective layer 5 is provided on the back of the macro pattern layer 4; among them, the micro lens array layer includes a number of spherical micro lenses 2 arranged in an array, and the micro picture and text array layer includes a number of micro pictures 3 in an array. The micro lens array layer cooperates with the micro graphic array layer to produce a three-dimensional effect. Observing the above naked-eye three-dimensional printed matter from the front, you can see the three-dimensional effect of sinking and distant view from any direction of the front.

[0040] Preferably, both the microlens 2 array and the micrograp...

Embodiment 2

[0051] The second embodiment of the present invention provides a method for producing naked-eye three-dimensional printed matter, such as Figure 1-4 As shown, the manufacturing method of the naked eye three-dimensional printed matter provided in the second embodiment of the present invention includes:

[0052] Step S1, a transparent sheet 1 is provided.

[0053] Step S2, using transparent ultraviolet curing ink on the front surface of the transparent sheet 1 to form a microlens array layer by 3D printing, and the microlens array layer includes a plurality of spherically-shaped microlenses 2 arranged in an array.

[0054] Step S3. Use ultraviolet curing ink to print the micro-graphics array layer and the macro-pattern layer 4 on the back of the transparent sheet 1. The micro-graphics array layer includes a number of micro-graphics 3 arranged in an array, and the micro-lens array layer and The micro-graphics array layer cooperates to produce a three-dimensional effect; specifically, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap