A method for high-precision camera calibration using low-precision two-dimensional planar targets

A two-dimensional plane and camera calibration technology, which is applied in image analysis, image enhancement, instruments, etc., can solve the problem of high cost and achieve the effect of reducing production cost and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0041] The invention discloses a method for realizing high-precision camera calibration with a low-precision two-dimensional plane target, which specifically includes the following steps:

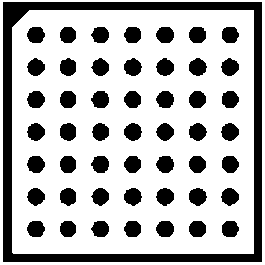

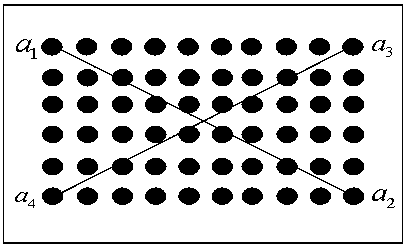

[0042] The first step: make the calibration board, such as image 3 As shown, it is assumed that there are l control points on the calibration board, and the control point is the center of each circle. Taking the center of the calibration plate as the origin, the horizontal right is the X axis, the horizontal downward is the Y axis, and the vertical calibration plate plane is the Z axis. The initial value of the coordinates of each control point in the world coordinate system is (X wi ,Y wi ,Z wi ), i=1,2,...l (l≥8). Among them, Z wi are initialized to 0. At the same time, accurately measure the distance between two relatively large co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com