Vortex-excitation piezoelectric energy harvester for monitoring wind power gear box

A wind power gearbox, piezoelectric energy capture technology, applied in generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., to achieve a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

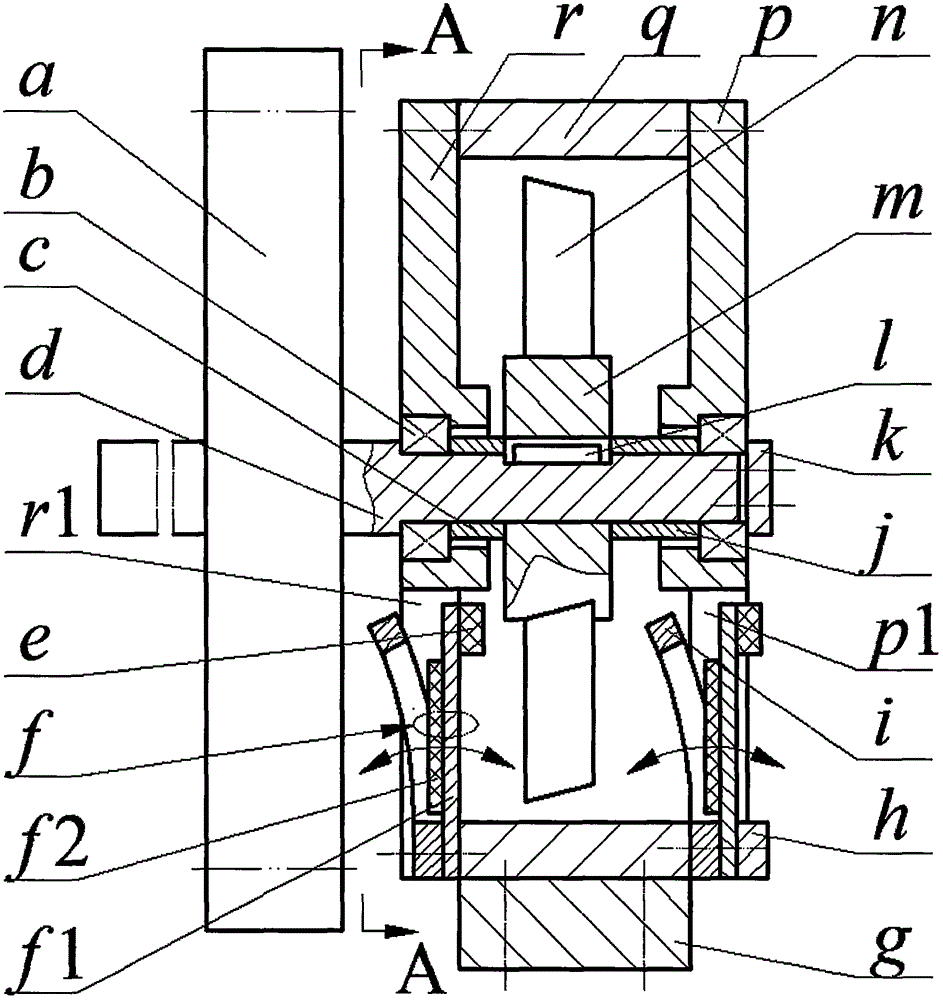

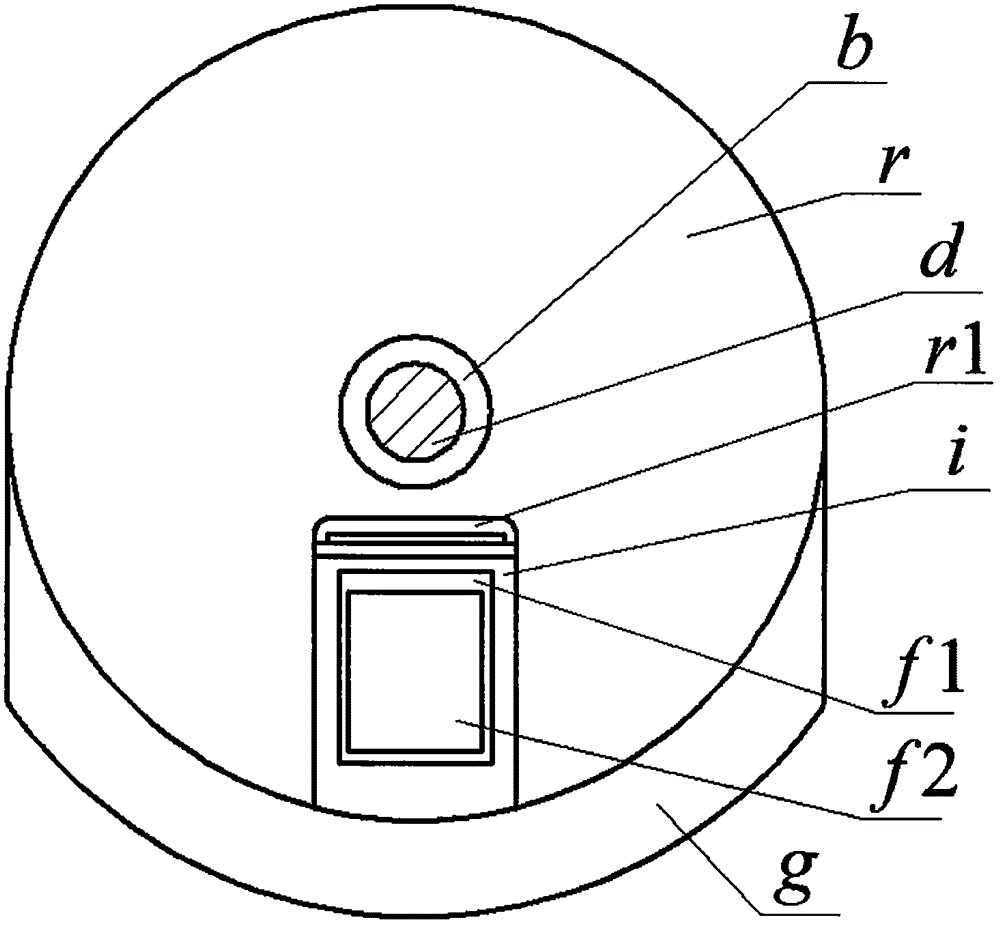

[0014] The gear a is installed on the main shaft d, and the main shaft d is sequentially covered with the left wall plate r with the outlet r1, the left bushing c, the rim m with the blade n installed, the right bushing j, and the The right wall plate p of the inlet p1, the end of the main shaft d is installed with a baffle k through screws; the left wall plate r and the right wall plate p are respectively sleeved on the main shaft d through the bearing b, and the inner part of the bearing b on the left wall plate r The left side of the ring leans against the shoulder of the main shaft d, and the right side of the inner ring of the bearing b on the wall plate p leans against the baffle k; the rim m and the main shaft d are connected by key 1, and the blade n and the rim There is a certain angle Q between the busbars of m; the two ends of the shell q are respectively connected with the left wall plate r and the right wall plate p through screws, and the outer wall of the shell q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com