A rotary blank clamping device suitable for automatic blank stacking machine

A technology of brick stacking machine and rotary clamp, which is applied in the direction of conveyor, object stacking, transportation and packaging, etc. It can solve the problems of reducing brick quality, brick falling damage, brick stacking efficiency reduction, etc., to improve stacking efficiency, Prevents extrusion damage and enhances positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

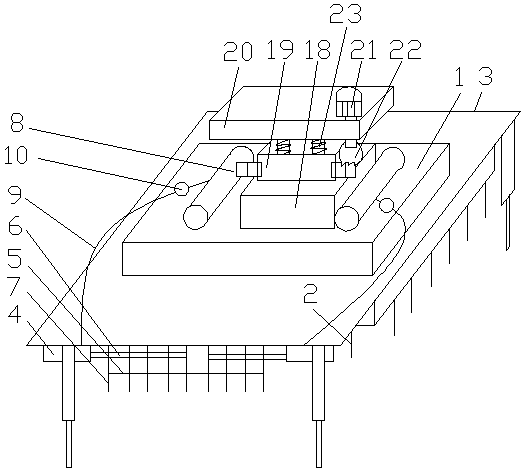

[0031] see figure 1 , a rotary clamping device suitable for automatic billet stacking machines, including a chuck 1 and a clamp 2, the bottom of the chuck 1 is connected with a telescopic frame 3, the clamp 2 is fixed on the inner wall of the telescopic frame 3, and the clamp 2 It is composed of a cylinder 4, a connecting rod 5, a telescopic rod 6 and at least two side-by-side splints 7, the cylinder 4 is fixed on the telescopic frame 3, the telescopic rod 6 is connected with the piston rod of the cylinder 4, and the splint 7 passes through On the telescopic rod 6, two adjacent splints 7 are connected through the connecting rod 5 to form a linkage. The chuck 1 is connected with an air storage tank 8, and the cylinder 4 communicates with the air storage tank 8 through the air distribution pipe 9. The air distribution pipe 9 The air inlet end of the air pressure regulator 10 is connected, the top of the chuck 1 is connected with a base 18, the base 18 is connected with a slewing...

Embodiment 2

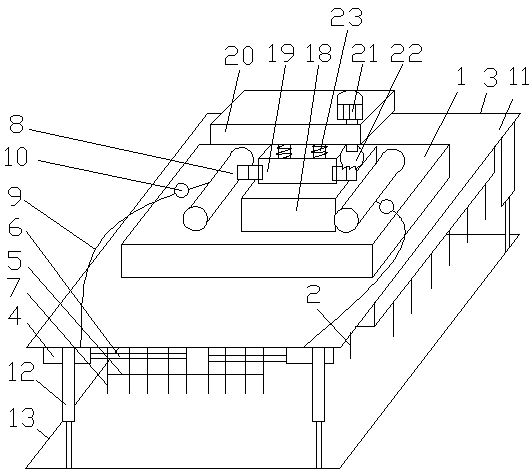

[0034] see figure 2 , a rotary clamping device suitable for automatic billet stacking machines, including a chuck 1 and a clamp 2, the bottom of the chuck 1 is connected with a telescopic frame 3, the clamp 2 is fixed on the inner wall of the telescopic frame 3, and the clamp 2 It is composed of a cylinder 4, a connecting rod 5, a telescopic rod 6 and at least two side-by-side splints 7, the cylinder 4 is fixed on the telescopic frame 3, the telescopic rod 6 is connected with the piston rod of the cylinder 4, and the splint 7 passes through On the telescopic rod 6, two adjacent splints 7 are connected through the connecting rod 5 to form a linkage. The chuck 1 is connected with an air storage tank 8, and the cylinder 4 communicates with the air storage tank 8 through the air distribution pipe 9. The air distribution pipe 9 The air inlet end of the air pressure regulator 10 is connected, the top of the chuck 1 is connected with a base 18, the base 18 is connected with a slewin...

Embodiment 3

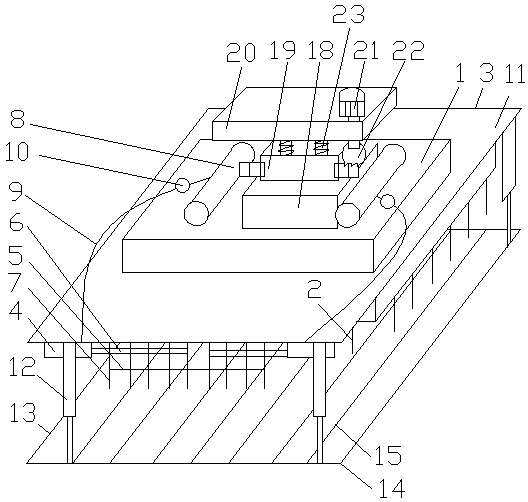

[0038] see image 3 , a rotary clamping device suitable for automatic billet stacking machines, including a chuck 1 and a clamp 2, the bottom of the chuck 1 is connected with a telescopic frame 3, the clamp 2 is fixed on the inner wall of the telescopic frame 3, and the clamp 2 It is composed of a cylinder 4, a connecting rod 5, a telescopic rod 6 and at least two side-by-side splints 7, the cylinder 4 is fixed on the telescopic frame 3, the telescopic rod 6 is connected with the piston rod of the cylinder 4, and the splint 7 passes through On the telescopic rod 6, two adjacent splints 7 are connected through the connecting rod 5 to form a linkage. The chuck 1 is connected with an air storage tank 8, and the cylinder 4 communicates with the air storage tank 8 through the air distribution pipe 9. The air distribution pipe 9 The air inlet end of the air pressure regulator 10 is connected, the top of the chuck 1 is connected with a base 18, the base 18 is connected with a slewing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com