Bacterium with increased tolerance to butyric acids

A technology for bacteria, tolerance, applied in the direction of bacteria, methods using microorganisms, methods based on microorganisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0052] The following examples further illustrate the invention but, of course, should not be construed as in any way limiting its scope.

example 1

[0054] This example demonstrates the typical growth of Clostridium strains.

[0055] Clostridium strains were grown at 37°C in PETC medium, pH 5.6, using standard anaerobic techniques (Hungate, Meth Microbiol, 3B:117-132, 1969; Wolfe, Microbial Physiology Advances (Adv Microb Physiol), 6:107-146, 1971). Fructose (heterotrophic growth) or 30 psi CO-containing steel plant gas (collected on-site at New Zealand Steel in Glenbrook, NZ) in the headspace; composition: 44% CO, 32% N 2 , 22%CO 2 , 2%H 2 ) (autotrophic growth) as a substrate. For solid media, 1.2% Bacterial Agar (BD, Frankton Lakes, NJ 07417, USA) was added.

[0056]

[0057]

example 2

[0059] This example demonstrates the toxicity of 2-HIBA to Clostridium autoethanogenum LZ1561 in serum bottles and continuous stirred tank reactors (CSTR).

[0060] serum bottle

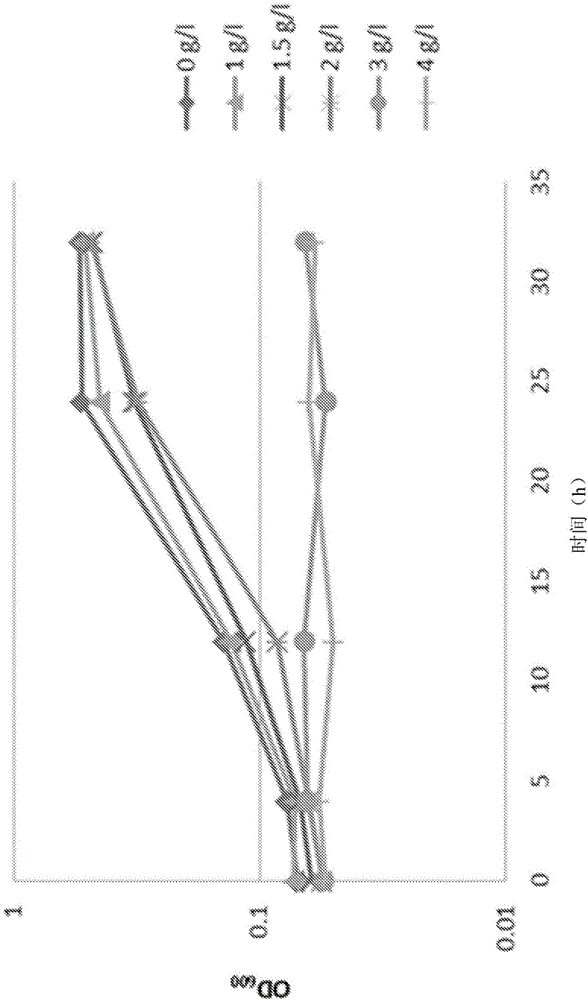

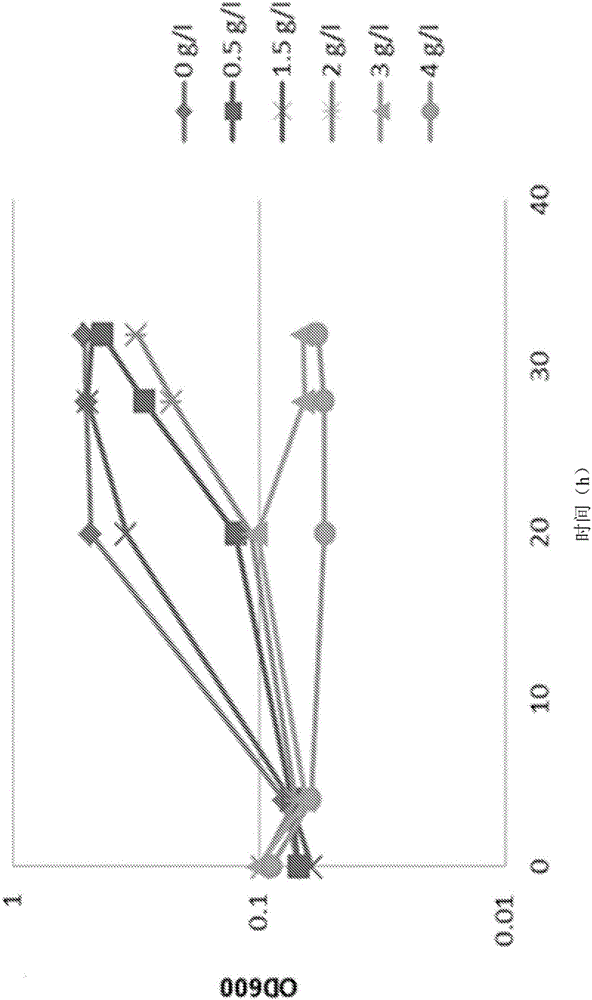

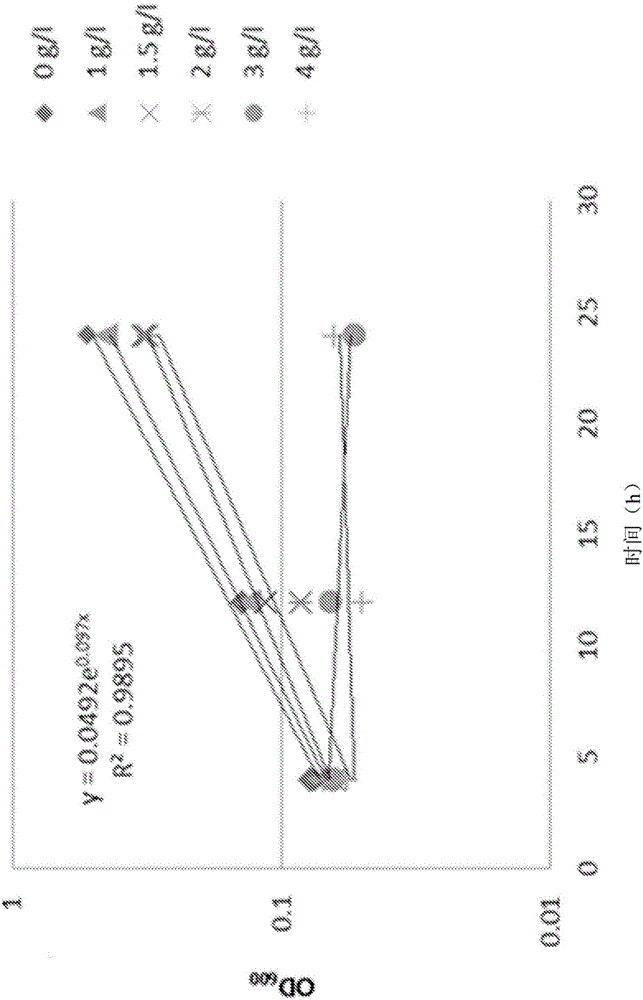

[0061] Two sets of serum bottle experiments were performed with media containing 0, 0.5, 1, 1.5, 2, 3 or 4 g / L 2-HIBA. The average of optical density (OD) data from two sets of growth experiments is plotted. Data points outside the intuitively observed exponential growth phase were removed and the growth rate (μ) for each concentration of 2-HIBA was calculated by fitting an exponential trend line (Figure 1).

[0062] Figure 1 shows the growth rate of C. autoethanogenum challenged with different concentrations of 2-HIBA. Figure 1A and Figure 1B Individual differences in the growth curves of the two groups of growth experiments (n=3) are shown. Figure 1C and Figure 1D respectively show the corresponding Figure 1A and Figure 1B The exponential fitting line of . Figure 1C Further display o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com