Wood cutting polishing device

A technology for cutting and grinding wood, applied in woodworking safety devices, wood processing equipment, circular saws, etc., can solve problems such as potential safety hazards, flying burrs, and danger to operators, so as to avoid indirect contact and protect personal The effect of safety and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

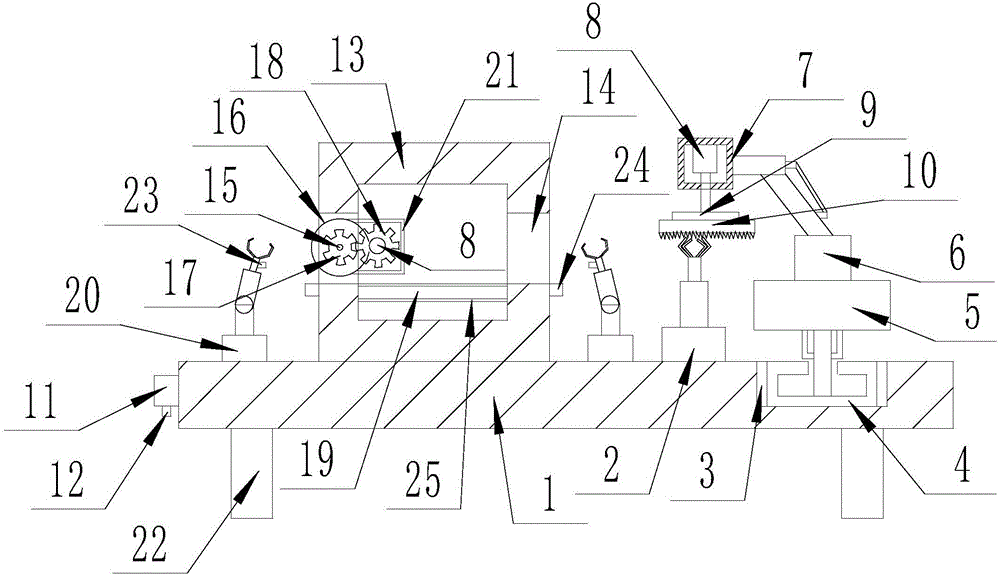

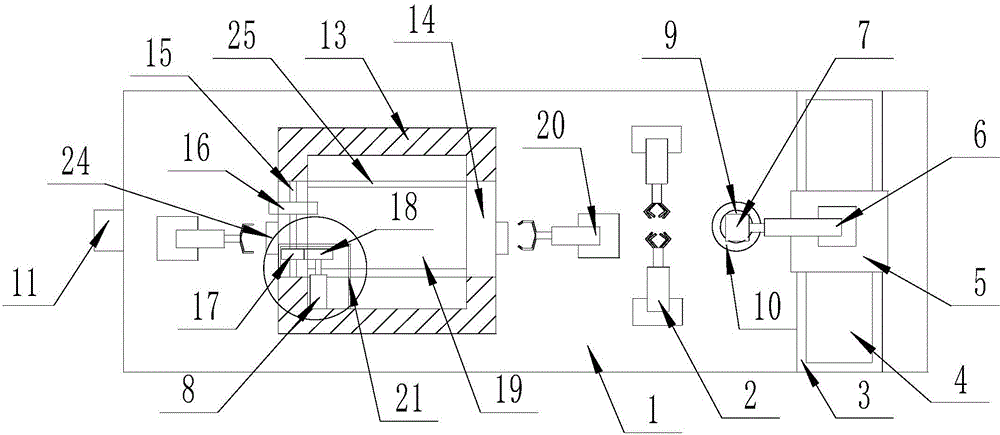

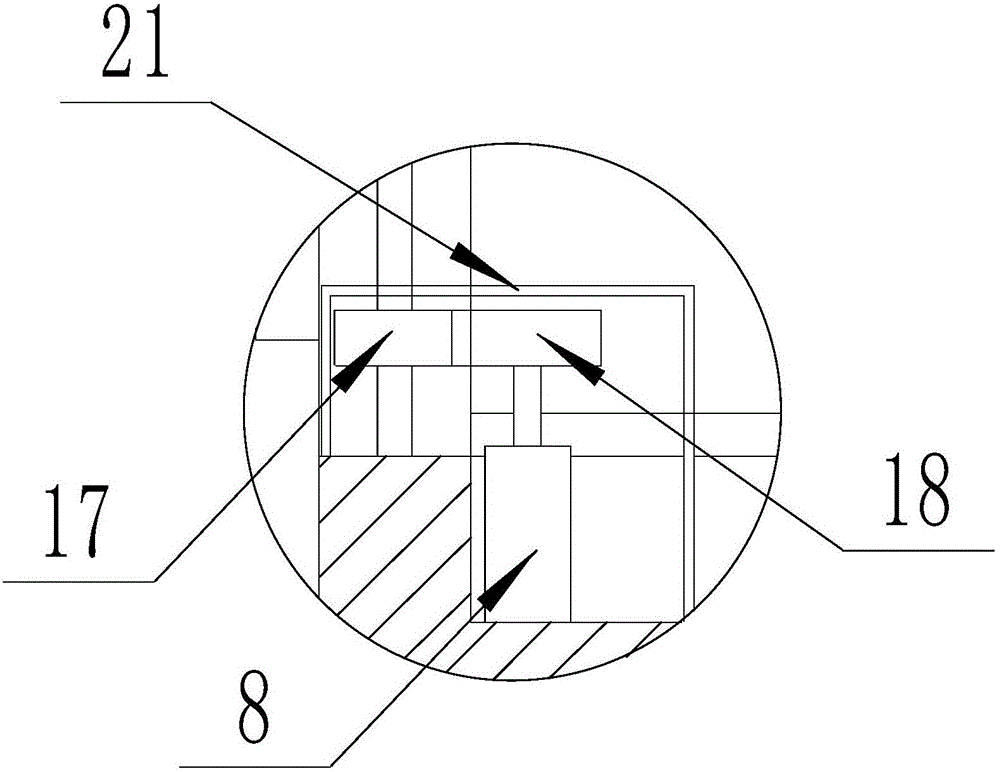

[0015] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-3 As shown, a wood cutting and polishing device includes an operating table (1), the upper surface of the operating table (1) is provided with a cutting mechanism, one side of the cutting mechanism is provided with a group of mechanical grippers (2), and the one A rectangular slot (3) is processed on one side of the set of mechanical grippers (2) and above the operating table (1), and a horizontal slide rail (4) is arranged in the rectangular slot (3), and the horizontal slide An electric trolley (5) is provided on the rail (4), a mechanical arm (6) is provided on the upper surface of the electric trolley (5), and a mounting box (7) is provided at the front end of the mechanical arm (6). (7) is provided with a rotating motor (8) with the rotating end downward, and the rotating end of the rotating motor (8) is fixedly connected with the fixed disc (9) arranged und...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com