Sieving feeding device

A feeding device and screening technology, applied in the field of plastic production, can solve the problems of unfavorable plastic particles, increased processing steps, and reduced efficiency, and achieve the effects of convenient collection, full screening, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

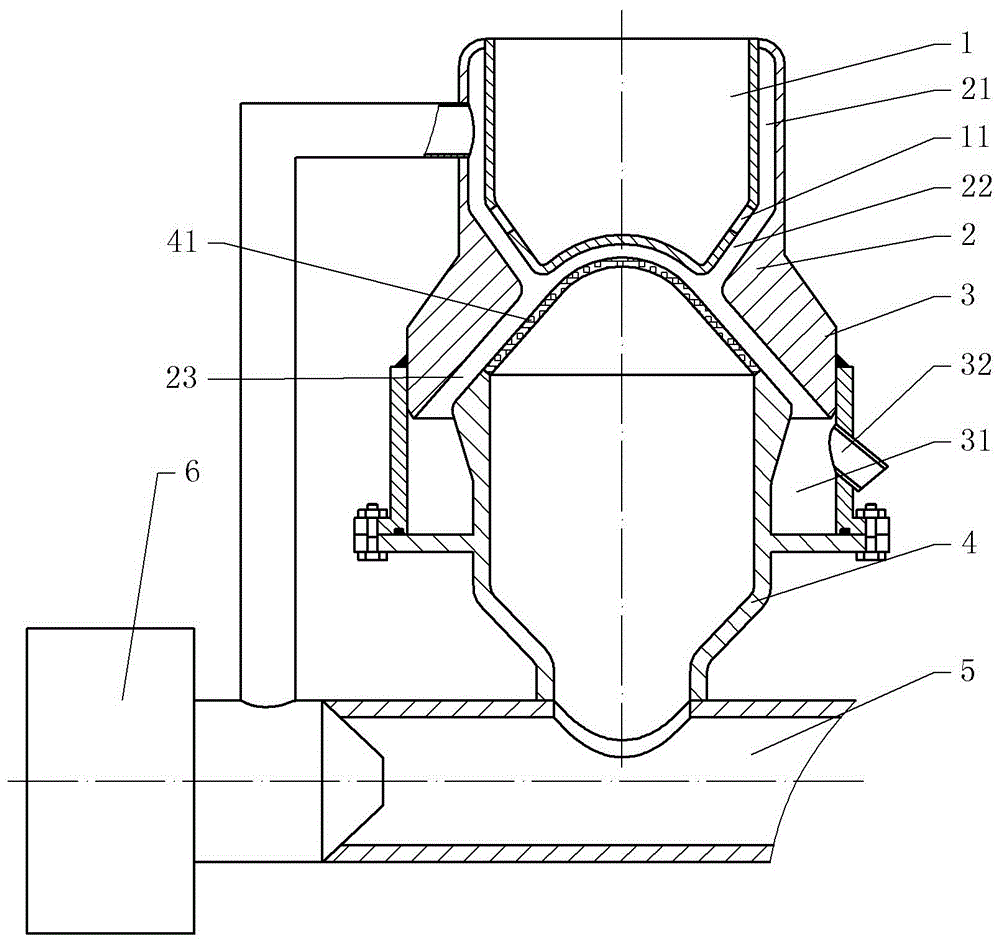

[0018] The reference signs in the drawings of the description include: hopper 1, discharge joint 2, connecting pipe 3, material selection pipe 4, feeding pipe 5, feeding fan 6, discharge hole 11, air duct 21, discharge loop 22, Annular feed port 23, waste bin 31, waste outlet 32, conical screen 41,.

[0019] The embodiment is basically as figure 1 Shown:

[0020] The screening and feeding device of this embodiment includes a hopper 1, a discharge joint 2, a material selection pipe 4, a feed pipe 5 and a feed fan 6; the discharge joint 2 is socketed on the outer periphery of the hopper 1, and the upper end of the discharge joint 2 is welded on On the side wall of the hopper 1; the lower end of the hopper 1 is in the shape of an inverted cone, and the upper side wall of the inverted tapered side wall is provided with a discharge hole 11; a gap with equal spacing is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com