Carrier taking and placing mechanism

A carrier and cylinder technology, which is applied in the field of carrier pick-and-place equipment, can solve the problems of easy falling off, machining shape size error, etc., and achieve the effect of improving the repeatability of positioning accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0021] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

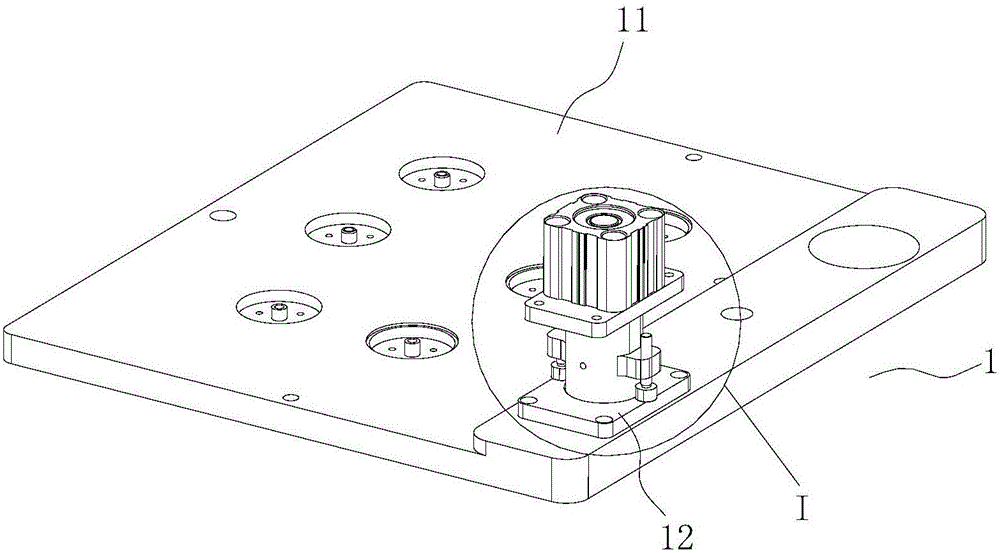

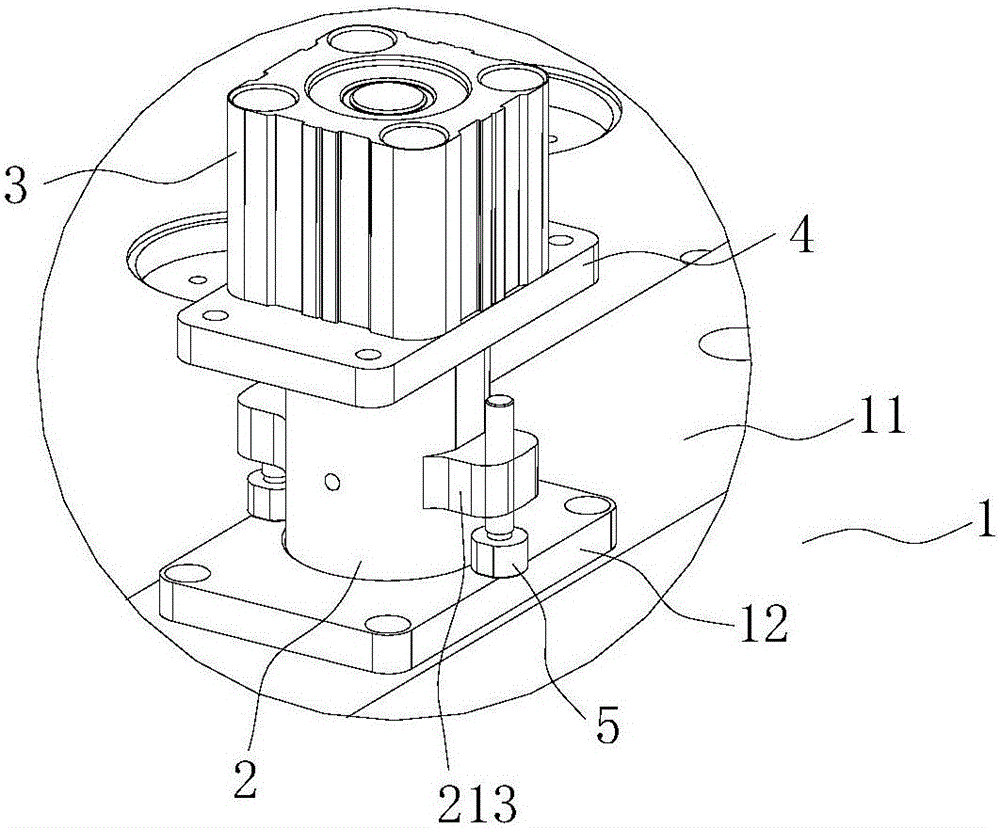

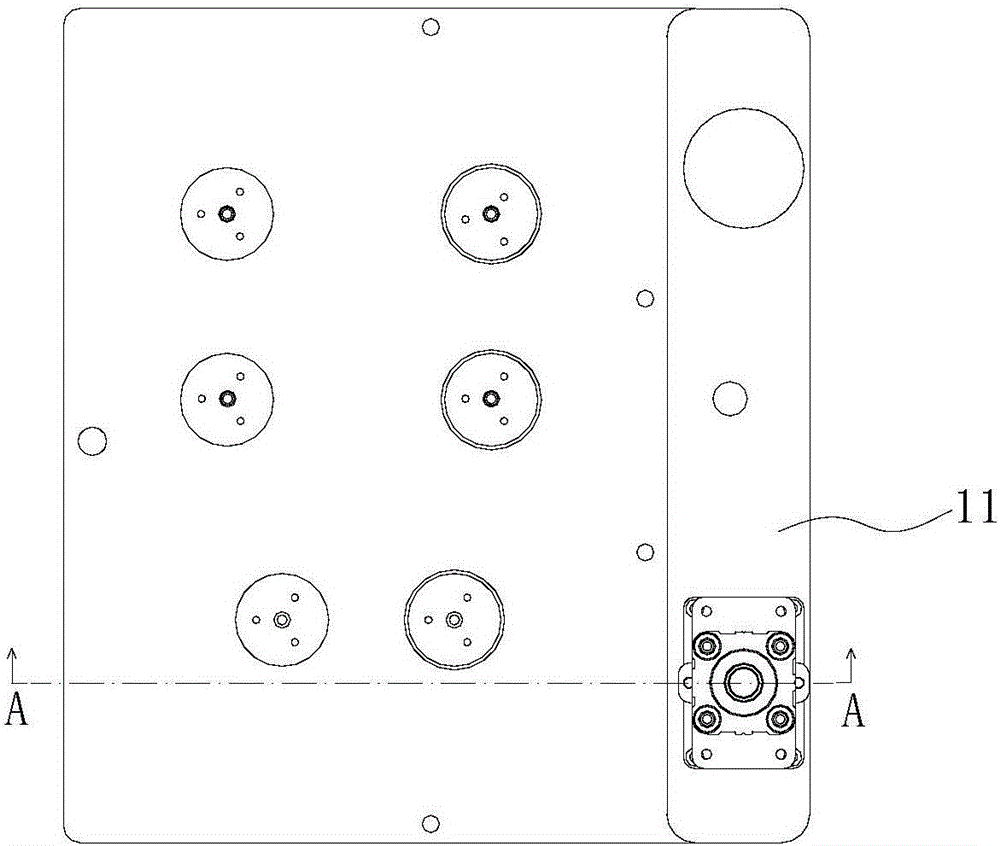

[0022] This embodiment provides a carrier pick-and-place mechanism, such as Figure 1 to 5 As shown, the carrier pick-and-place mechanism includes a carrier 1, an adjusting assembly 2, an air cylinder 3, a fixed plate 4, a ball 6, a moving shaft 8 and a driving assembly (not shown in the figure), wherein,

[0023] The carrier 1 includes a carrier body 11 on which a fixed block 12 is fixedly arranged therethrough, and the carrier body 11 and the fixed block 12 are connected by screws; the fixed block 12 is provided with A perforating hole, one end of the perforating hole is set as a tapered hole 121, the diameter of the tapered hole 121 gradually increasing along the extending direction of the piston rod 31 of the cylinder 3.

[0024] The adjusting component 2 is slidably penetrated through the carrier 1. Specifically, refer to Fig...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap