Gap eliminating transmission case

A technology of transmission box and transmission shaft, which is applied in the direction of transmission box, metal processing, components with teeth, etc. Accuracy does not meet the requirements and other problems, to achieve the effect of good positioning accuracy and repeated positioning accuracy, simple structure and compact internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

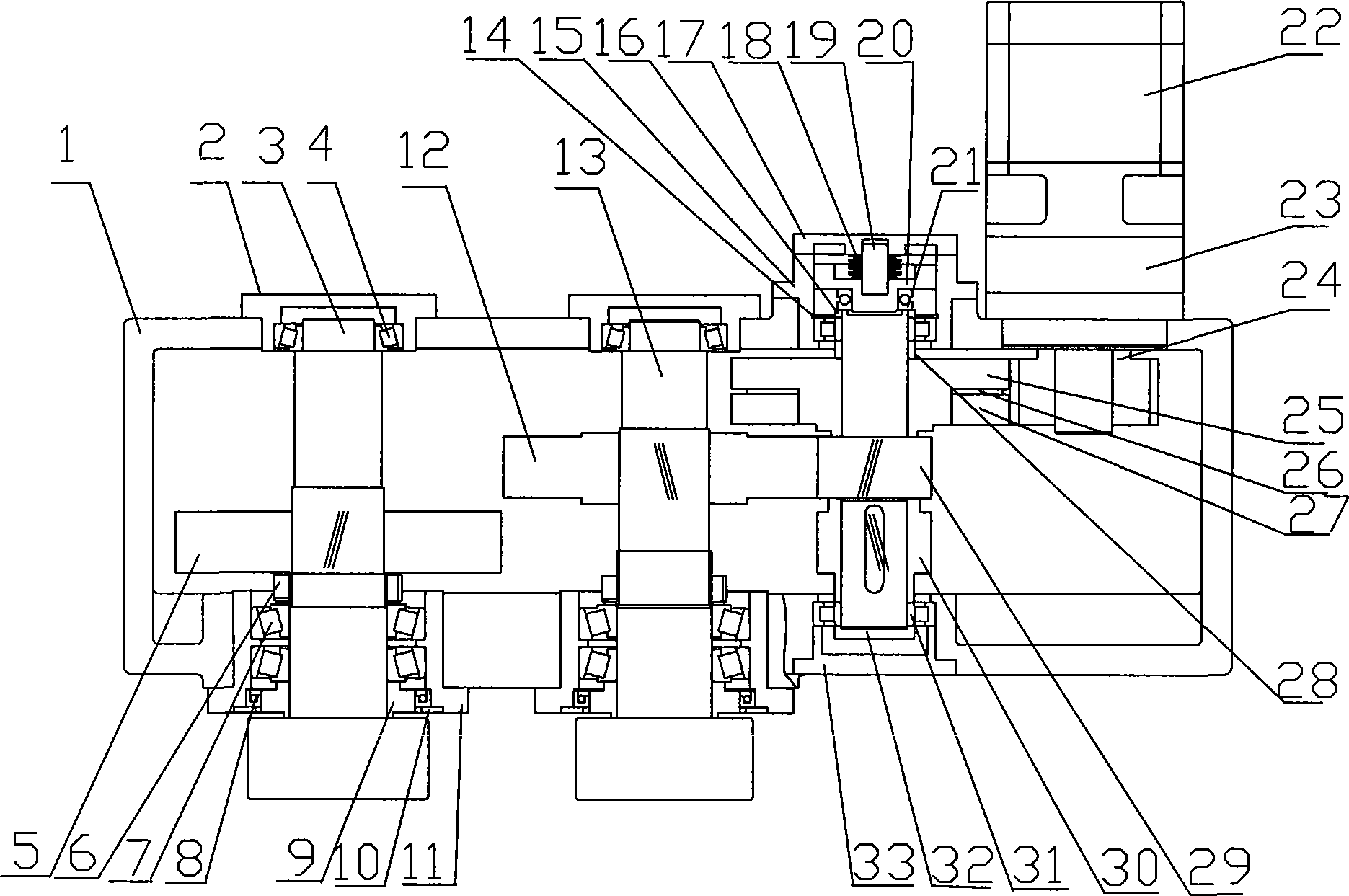

[0013] like figure 1 As shown, it includes box body 1, first bearing seat 2, first output transmission shaft 3, tapered roller bearing 4, first helical gear 5, lock nut 6, tapered roller bearing 7, sealing ring 8, sleeve 9 , the first cover 10, the second bearing seat 11, the second helical gear 12, the second output transmission shaft 13, the retaining ring 14 for the hole, the third bearing seat 15, the first spacer ring 16, the gland 17, the disc spring 18. Shaft 19, spring seat 20, thrust ball bearing 21, motor 22, planetary gearbox 23, third helical gear 24, fourth helical gear 25, adjustment pad 26, fifth helical gear 27, second spacer 28, Helical gear transmission shaft 29, sixth helical gear 30, cylindrical roller bearing 31, second cover 32, third cover 33, and the like.

[0014] This new type of use mainly uses the first output drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com